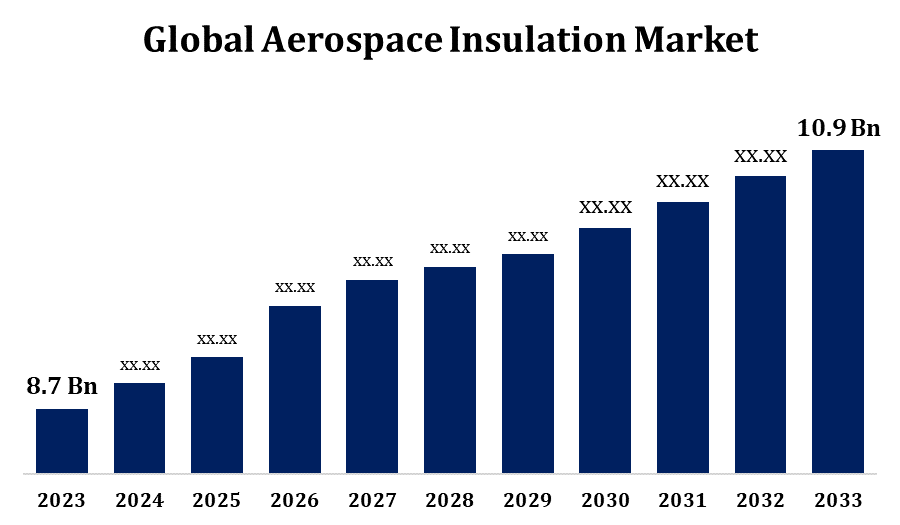

Global Aerospace Insulation Market Size To Worth USD 10.9 Billion By 2033 | CAGR of 2.28%

Category: Aerospace & DefenseGlobal Aerospace Insulation Market Size To Worth USD 10.9 Billion By 2033

According to a research report published by Spherical Insights & Consulting, the Global Aerospace Insulation Market Size to Grow from USD 8.7 Billion in 2023 to USD 10.9 Billion by 2033, at a Compound Annual Growth Rate (CAGR) of 2.28% during the forecast period.

Get more details on this report -

Browse key industry insights spread across 226 pages with 110 Market data tables and figures & charts from the report on the “Global Aerospace Insulation Market Size, Share, and COVID-19 Impact Analysis, By Product (Thermal, Acoustic, Electric), By Material (Ceramic Materials, Mineral Wool, Foamed Plastics, Fiberglass, Others), By End Use (Commercial Aircraft, Military Aircraft), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2023 – 2033.” Get Detailed Report Description Here:https://www.sphericalinsights.com/reports/aerospace-insulation-market

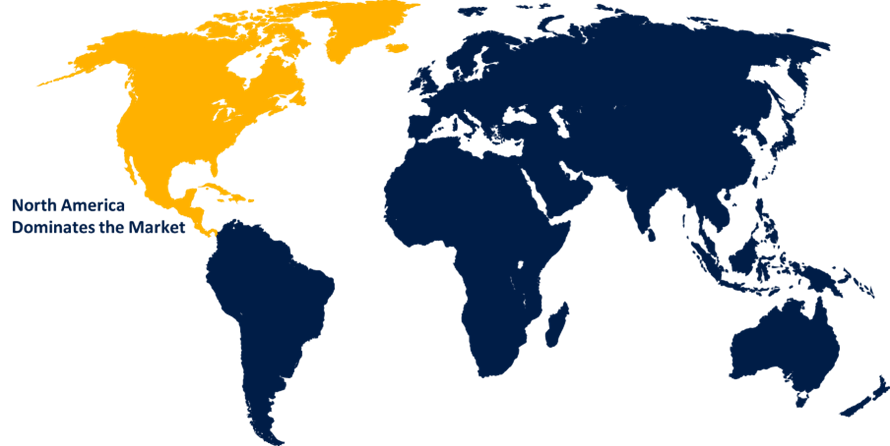

Due to strict regulations that prioritise noise reduction and fuel efficiency, as well as an increase in air travel, the aerospace insulation market is expanding rapidly. Foams, fibreglass, and ceramic-based goods are examples of insulation materials that are widely used in aeroplanes to improve fire safety, acoustic comfort, and thermal management. One major trend influencing the industry is the growing need for lightweight materials that reduce total weight without sacrificing functionality. Manufacturers are now able to provide creative insulation solutions specifically suited for the general aviation, military, and commercial aviation sectors because to technological and material science advancements. The market is dominated by the well-established aerospace industries of North America and Europe, with the Asia-Pacific area emerging as a promising hub for growth due to the expansion of regional aircraft fleets.

Aerospace Insulation Market Value Chain Analysis

The value chain for the aerospace insulation market includes multiple critical phases, ranging from acquiring raw materials to delivering final products. The first step involves obtaining raw ingredients from chemical and material manufacturers, such as fibreglass, ceramics, and foams. Manufacturers of insulation next process and transform these materials into a variety of insulation products, including panels, blankets, and coatings. After that, in order to satisfy legal requirements for fire safety, weight optimisation, and thermal and acoustic insulation, these goods go through extensive testing. In order to guarantee that these items are available to aircraft manufacturers and maintenance, repair, and overhaul (MRO) service providers, distributors and suppliers are essential. Finally, the integration of insulation solutions by aerospace businesses into aircraft systems results in improved passenger comfort, safety, and fuel efficiency for both commercial and military aircraft.

Aerospace Insulation Market Opportunity Analysis

Growing air travel demand, aircraft modernisation initiatives, and strict safety and environmental impact rules are driving growth in the aerospace insulation market. There is room for innovation in the move towards eco-friendly and lightweight materials, especially in the creation of sophisticated composites and nanomaterials that lighten weight and increase fuel economy. Growing aeroplane fleets are opening up new markets for insulation suppliers, particularly in the developing economies of the Asia-Pacific region and the Middle East. The need for high-performance insulation solutions is further fuelled by the growing emphasis in the premium and business class segments on improving passenger comfort and minimising cabin noise. Technological innovations that offer new growth opportunities for enterprises looking to meet changing industry standards and sustainability goals include 3D printing and smart insulating materials with self-healing and adaptable capabilities.

The aerospace insulation market is experiencing a surge in demand for corrosion-resistant insulation solutions and fuel-efficient engine technologies. This trend stems from the necessity to improve aircraft longevity, performance, and environmental sustainability. Materials like ceramic-based composites and advanced polymers are essential for safeguarding critical aircraft components against harsh operating conditions, moisture, and temperature variations. Additionally, the focus on fuel-efficient engines is driving the use of lightweight insulation products that aid in overall weight reduction while preserving thermal and acoustic properties. These advancements are particularly significant for newer aircraft models, which require advanced materials to comply with strict regulatory standards and promote energy-efficient performance. As a result, manufacturers are investing in research and development to create innovative insulation solutions that fulfill the dual needs of durability and efficiency in aerospace applications.

Insights by Material

The ceramic material segment accounted for the largest market share over the forecast period 2023 to 2033. Ceramics are becoming more and more popular in applications where high-temperature insulation is needed, like heat shields, exhaust systems, and engine nacelles. They are perfect for use in hostile situations because of their innate resistance to fire and corrosion, which ensures the safety and longevity of important components. The use of ceramic-based insulation is increasing due to the need for lightweight, fuel-efficient aircraft, as it can lower overall weight of the aircraft without sacrificing performance. Furthermore, developments in ceramic matrix composites (CMCs) are making it possible to create next-generation insulating solutions that support greater operating temperatures and improve engine performance, which lowers emissions and improves fuel efficiency.

Insights by Product

The thermal insulation segment accounted for the largest market share over the forecast period 2023 to 2033. Thermal insulation materials are crucial for preserving operating efficiency and passenger comfort in modern aeroplanes since they operate in extremely cold temperatures, ranging from high altitudes to below zero. Fibreglass, foam, and ceramic-based products are examples of lightweight, high-performance insulating materials that are commonly used to minimise heat transmission, increase fuel efficiency, and reduce energy loss. The category is growing due in part to an increasing focus on creating innovative materials with improved fire resistance and thermal conductivity. In addition, growing investments in the development of recyclable, environmentally friendly thermal insulation materials support industry sustainability objectives and open up new market prospects.

Insights by End Use

The commercial segment accounted for the largest market share over the forecast period 2023 to 2033. In order to lower noise levels, increase thermal and acoustic performance in cabins, and improve in-flight comfort—particularly in premium classes—airlines are investing in cutting-edge insulation materials. Adoption of lightweight insulating materials is also occurring in order to meet strict environmental laws and promote fuel efficiency. Demand in this market is being further stimulated by the spike in deliveries of new aircraft from significant manufacturers such as Boeing and Airbus, as well as by retrofitting activities for already-existing fleets. Furthermore, expanding airline operations in developing nations, especially in the Middle East and Asia-Pacific region, are giving insulation suppliers significant chances to meet a range of demands in the commercial aviation industry.

Insights by Region

Get more details on this report -

North America is anticipated to dominate the Aerospace Insulation Market from 2023 to 2033. Key growth factors in the region include the adoption of improved materials for thermal, acoustic, and fire insulation solutions, as well as a focus on technological innovation. Manufacturers are forced to utilise high-performance insulating materials due to strict regulatory criteria set by organisations such as the Federal Aviation Administration (FAA), which drives up demand in the industry. The main contributor is the United States, which produces more military and commercial aircraft than any other country and has a robust defence industry. Furthermore, the demand for fuel-efficient, lightweight aircraft as well as other aspects of sustainable aviation has raised the use of sophisticated insulating technologies. Canada contributes as well, increasing its funding for regional aviation initiatives.

Asia Pacific is witnessing the fastest market growth between 2023 to 2033. Leading nations in the world with strong need for both military and commercial aircraft are China, India, and Japan. The region's increasing emphasis on producing aircraft domestically and updating its current fleets encourages the use of cutting-edge insulating materials. High-performance thermal and acoustic insulation solutions are also becoming more and more necessary in order to improve passenger comfort and operational efficiency as low-cost airlines and new routes open up. Government regulations that are conducive to the development of aerospace and partnerships between domestic producers and multinational corporations are creating new avenues for insulation providers to build a significant presence in this profitable and quickly changing industry.

Recent Market Developments

- In January 2023, Aerogel Core Ltd. has created next-generation materials specifically designed for the aerospace and automotive industries. The company has launched ultra-light, low-carbon 'aerogel' insulation materials that are suitable for soundproofing and heat shielding in both aviation and automotive applications.

Major players in the market

- Duracote Corporation

- Rogers Corporation

- Dupont

- BASF SE

- 3M

- Esterline Technologies Corporation

- Triumph Group Inc.

- Zodiac Aerospace

- Evonik Industries

- Polymer Technologies Inc.

- Zotefoams

- UPF Corporation

- Boyd Corporation

- Johns Manville

- Orcon

- AVS Industries

- Others

Market Segmentation

This study forecasts revenue at global, regional, and country levels from 2023 to 2033.

Aerospace Insulation Market, Product Analysis

- Thermal

- Acoustic

- Electric

Aerospace Insulation Market, Material Analysis

- Ceramic Materials

- Mineral Wool

- Foamed Plastics

- Fiberglass

- Others

Aerospace Insulation Market, End Use Analysis

- Commercial Aircraft

- Military Aircraft

Aerospace Insulation Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?