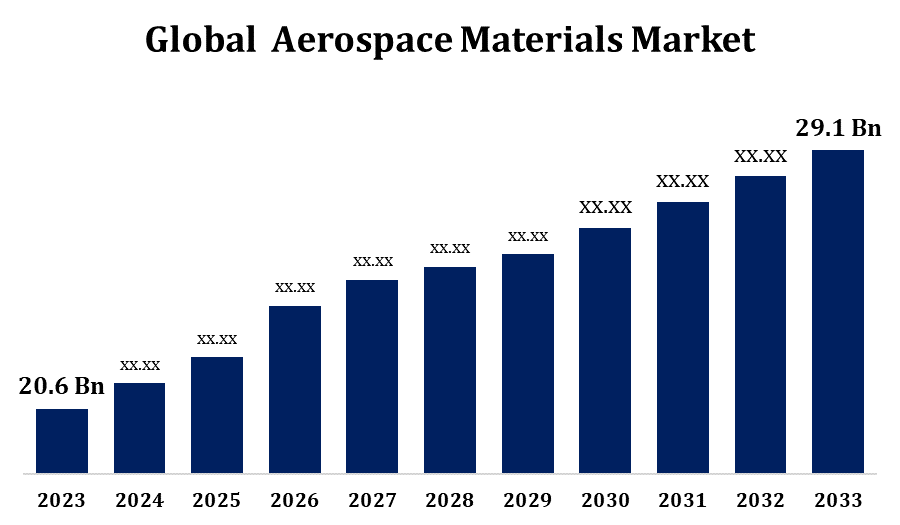

Global Aerospace Materials Market Size To Worth USD 29.1 Billion By 2033 | CAGR of 3.51%

Category: Aerospace & DefenseGlobal Aerospace Materials Market Size To Worth USD 29.1 Billion By 2033

According to a research report published by Spherical Insights & Consulting, the Global Aerospace Materials Market Size to Grow from USD 20.6 Billion in 2023 to USD 29.1 Billion by 2033, at a Compound Annual Growth Rate (CAGR) of 3.51% during the forecast period.

Get more details on this report -

Browse key industry insights spread across 218 pages with 110 Market data tables and figures & charts from the report on the “Global Aerospace Materials Market Size, Share, and COVID-19 Impact Analysis, By Product (Aluminum, Composites), By Application (Aerostructure, Propulsion System), By Aircraft Type (Commercial, Military), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2023 - 2033." Get Detailed Report Description Here:https://www.sphericalinsights.com/reports/aerospace-materials-market

Strong expansion in the aerospace materials market is being driven by the growing need for lighter, more fuel-efficient aircraft. Advanced materials with high strength-to-weight ratios, resistance to corrosion, and longevity, like composites, aluminium alloys, titanium, and superalloys, are being used more and more. In order to reduce weight and increase fuel efficiency, composite materials like carbon fibre reinforced polymers (CFRP) are being used more often in military and commercial aircraft. Further developments in manufacturing technologies, like 3D printing and additive manufacturing, are opening the door to more intricate designs and economical production methods. Increased air traveler volume and fleet growth, particularly in developing nations, support market demand even more. In order to create novel materials that will improve performance and sustainability in the aerospace industry, key players are concentrating on research and development as well as strategic partnerships.

Aerospace Materials Market Value Chain Analysis

Strong expansion in the aerospace materials market is being driven by the growing need for lighter, more fuel-efficient aircraft. Advanced materials with high strength-to-weight ratios, resistance to corrosion, and longevity, like composites, aluminium alloys, titanium, and superalloys, are being used more and more. In order to reduce weight and increase fuel efficiency, composite materials like carbon fibre reinforced polymers (CFRP) are being used more often in military and commercial aircraft. Further developments in manufacturing technologies, like 3D printing and additive manufacturing, are opening the door to more intricate designs and economical production methods. Increased air traveler volume and fleet growth, particularly in developing nations, support market demand even more. In order to create novel materials that will improve performance and sustainability in the aerospace industry, key players are concentrating on research and development as well as strategic partnerships.

Aerospace Materials Market Opportunity Analysis

A major development opportunity in the aerospace materials market is being driven by the growing demand for next-generation aircraft that prioritise fuel efficiency and sustainability. As manufacturers look to reduce weight and improve performance, the use of innovative materials such as ceramic matrix composites, titanium alloys, and carbon fibre composites is growing. More need for specialised materials that can tolerate high electrical and thermal loads is being created by the growth of electric and hybrid aircraft. Furthermore, developments in nanomaterials and additive manufacturing are creating more affordable production and improved material qualities, which are creating new opportunities for innovation. Increased investments in aviation infrastructure are being made in emerging countries in Latin America, the Middle East, and Asia-Pacific, which presents vendors with profitable opportunities.

The aerospace materials market is experiencing tremendous growth due to the increasing rate of replacement of ageing aircraft. The need for sophisticated materials is rising as airlines upgrade their fleets to increase safety, fuel efficiency, and environmental compliance. A move away from traditional metals is being driven by newer aircraft models that use lightweight composites, high-strength aluminium alloys, and titanium to lower total weight and fuel consumption. The phase-out of older aeroplanes is being accelerated by strict limits on emissions and noise pollution in developed nations such as North America and Europe. This replacement wave is also being fuelled by a surge in air travel and the demand for more dependable, long-lasting aircraft, which presents significant potential for producers and suppliers of materials specialising in next-generation aerospace materials.

The aerospace materials market is confronted with various obstacles, such as elevated production expenses and intricate manufacturing procedures linked to sophisticated materials like superalloys and composites. Adoption may be constrained, particularly by smaller businesses, due to the increased cost and duration of production caused by the requirement for specialised machinery and expert labour. Complying with strict regulations and testing specifications for materials used in aerospace applications can be difficult because it prolongs development schedules and necessitates strict compliance and certification. The dynamics of the market are further complicated by supply chain interruptions and the volatility of raw material prices, such as those of titanium and aluminium. Furthermore, the high expense of research and development required to innovate and enhance material attributes like strength and heat resistance could be a deterrent for new entrants and hinder the expansion of the industry as a whole.

Insights by Product

The titanium segment accounted for the largest market share over the forecast period 2023 to 2033. As titanium alloys reduce overall weight and improve fuel efficiency, they are being used more and more in vital aviation components like airframes, landing gears, and engine parts. The need for titanium materials is being driven by the expansion of commercial aircraft production as well as the growing emphasis on replacing ageing fleets. Additionally, the manufacturing of sophisticated fighter planes and military aircraft, which heavily rely on titanium, is rising as a result of increased defence spending and air traffic. Technological developments in titanium recycling and processing have also reduced the material's cost, encouraging broader use. As a result, it is anticipated that the titanium market sector would maintain its rapid growth trajectory in the aerospace materials market.

Insights by Application

The aerostructure segment accounted for the largest market share over the forecast period 2023 to 2033. Aerostructures need materials with great strength, durability, and lightweight qualities because they comprise vital parts like wings, fuselages, and empennages. Manufacturers are using more modern composites, such as carbon fibre reinforced polymers (CFRP) and high-strength aluminium and titanium alloys, in an effort to reduce aircraft weight, improve fuel efficiency, and minimise emissions. Furthermore, the trend in aircraft design towards modular aerostructures is increasing the need for creative material solutions. The use of new materials in aerostructures is being further accelerated by growing investments in next-generation aircraft, including electric and hybrid models, which is cementing the market expansion of this segment.

Insights by Aircraft Type

The commercial segment accounted for the largest market share over the forecast period 2023 to 2033. Airlines are making investments in lightweight materials including titanium, aluminium alloys, and composites in order to meet strict pollution rules, save maintenance costs, and improve fuel efficiency. Further driving demand for sophisticated materials is the tendency of replacing older aeroplanes with newer, fuel-efficient variants. Furthermore, the necessity for longer-haul aircraft and the emergence of low-cost airlines in emerging markets are driving up demand for high-performance materials from manufacturers. The commercial aerospace industry is seeing continuous growth because to the novel designs made possible by technological breakthroughs in materials and production methods.

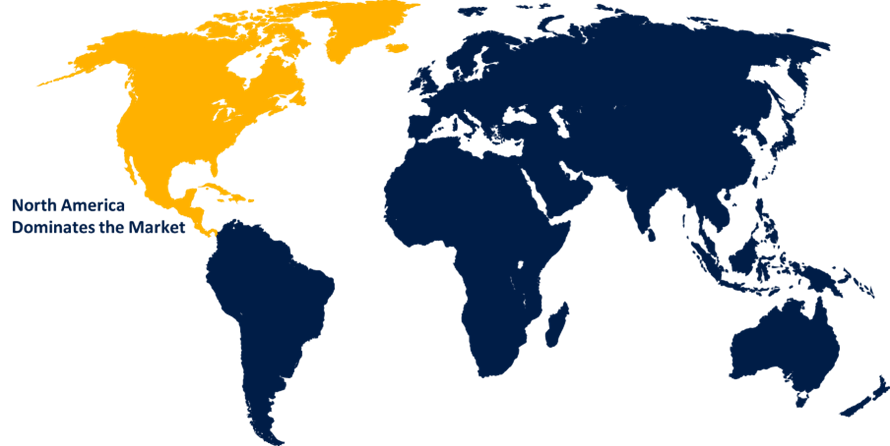

Insights by Region

Get more details on this report -

North America is anticipated to dominate the Aerospace Materials Market from 2023 to 2033. The region's growth is mostly driven by large investments in space exploration and defence, along with a major emphasis on modernising the fleets of commercial aircraft. The focus on improving fuel efficiency and lowering emissions is driving up demand for lightweight materials like carbon fibre composites and titanium alloys. In addition, the increasing rate at which outdated aeroplanes are being replaced is driving up material demand. The market for advanced materials in North America is growing as a result of partnerships between material suppliers and aircraft original equipment manufacturers (OEMs) and advancements in production methods like additive manufacturing.

Asia Pacific is witnessing the fastest market growth between 2023 to 2033. Due to investments in new manufacturing facilities and MRO (maintenance, repair, and overhaul) centres, the region is starting to emerge as a major player in aerospace production. The need for cutting-edge materials including composites, speciality metals, and aluminium alloys has increased as a result. The adoption of lightweight materials to improve fuel efficiency and performance is being further driven by the development of domestic aircraft programs, such as Japan's Mitsubishi SpaceJet and China's COMAC C919. Moreover, the region's emphasis on growing its space and defence industries opens up profitable prospects for manufacturers of aerospace materials, establishing Asia-Pacific as a major player in the market.

Recent Market Developments

- In December 2023, Teijin Limited declared that production and sales of TenaxTM Carbon Fibre will commence. Remaining components from biomass products and sustainable acrylonitrile (AN) waste are used to make TenaxTM Carbon Fibre. Among other businesses, the aerospace industry uses the product.

Major players in the market

- Huntsman International LLC

- Toray Composites America, Inc.

- VSMPO-AVISMA

- Arconic Inc.

- Kobe Steel, Ltd.

- Allegheny Technologies

- Cytec Solvay Group

- Hexcel Corp.

- Novelis

- Constellium N.V.

- SGL Carbon

- thyssenkrupp Aerospace

- Formosa Plastics Corp.

- Strata Manufacturing PJSC

- Teijin Ltd.

- Others

Market Segmentation

This study forecasts revenue at global, regional, and country levels from 2023 to 2033.

Aerospace Materials Market, Product Analysis

- Aluminum

- Composites

Aerospace Materials Market, Application Analysis

- Aerostructure

- Propulsion System

Aerospace Materials Market, Aircraft Type Analysis

- Commercial

- Military

Aerospace Materials Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?