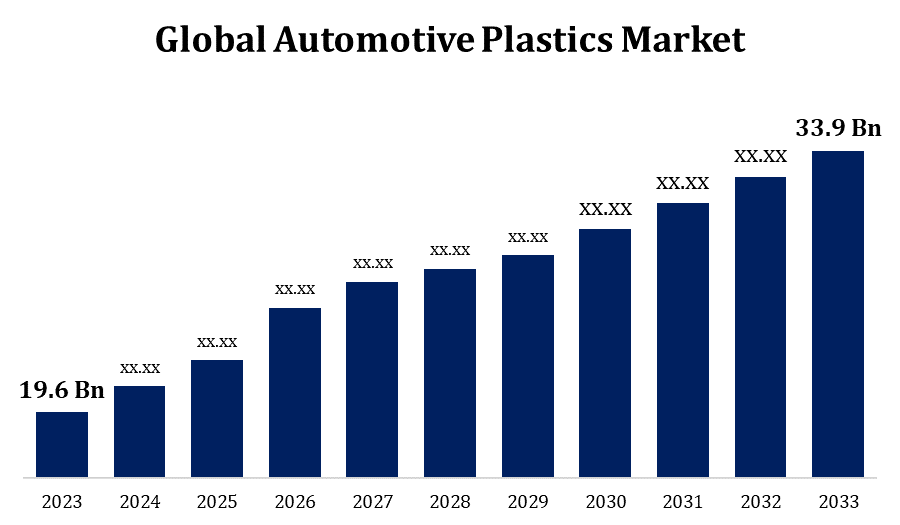

Global Automotive Plastics Market Size To Worth USD 33.9 Billion By 2033 | CAGR of 5.63%

Category: Chemicals & MaterialsGlobal Automotive Plastics Market Size To Worth USD 33.9 Billion By 2033

According to a research report published by Spherical Insights & Consulting, the Global Automotive Plastics Market Size to grow from USD 19.6 Billion in 2023 to USD 33.9 Billion by 2033, at a Compound Annual Growth Rate (CAGR) of 5.63% during the forecast period.

Get more details on this report -

Browse key industry insights spread across 200 pages with 120 Market data tables and figures & charts from the report on the "Global Automotive Plastics Market Size By Type (ABS, Polyamide, Polypropylene), By Application (Interior, Exterior, Under bonnet), By Region, And Segment Forecasts, By Geographic Scope And Forecast to 2033." Get Detailed Report Description Here: https://www.sphericalinsights.com/reports/automotive-plastics-market

The automotive plastics market is expanding and playing an important role in the evolution of the automotive industry. Plastics are replacing traditional materials in a range of automotive components due to their lightweight nature, fuel efficiency, and design flexibility. This modification contributes to improved vehicle performance and a lower environmental impact. The rising demand for lightweight automobiles to improve fuel efficiency, stringent environmental restrictions, and the need for creative design solutions are all driving forces in the automotive plastics business. Plastics are used in interior and exterior components, as well as under-the-hood and battery components in electric vehicles.

Automotive Plastics Market Value Chain Analysis

The value chain starts with the creation of raw materials used in the production of automotive plastics, such as petrochemicals or bio-based polymers. Polymer makers convert basic materials into a variety of polymers with the properties required for automotive applications. Polymer resins are used by plastic component manufacturers to build specific automotive parts and components. Injection moulding, extrusion, and thermoforming are all examples of this. Automotive manufacturers incorporate plastic components into the overall car assembly process. The final plastic components are transported to vehicle assembly plants via a logistical network. The third stage is concerned with consumer automobile use. Plastic components contribute to the overall design, safety, and functionality of the vehicle.

Automotive Plastics Market Opportunity Analysis

The vehicle industry is seeing a surge in demand for lightweight materials as it places a greater emphasis on fuel efficiency and environmental sustainability. Automotive plastics offer a solution because they are lighter than traditional materials like metal, resulting in better fuel efficiency. The increasing popularity of electric vehicles creates a significant potential for the automotive plastics industry. Plastics are used in components of electric vehicles such as battery casings, interior parts, and lightweight structural sections. Plastics in automobiles are critical for increasing interior aesthetics and design flexibility. The desire for visually appealing and configurable interiors creates an opportunity for plastics manufacturers to offer novel automobile interior solutions. Because the vehicle industry is global, there are opportunities for market expansion in a variety of regions.

When disposable income rises, consumers' purchasing power may improve, resulting in increased demand for vehicles. As a result, demand for automotive plastics, which are widely used in current car production, is increasing. A preference for premium and high-end vehicles is typically correlated with higher discretionary money. High-quality automotive plastics, for example, are widely utilised in these vehicles to improve appearances, performance, and overall driving experience. Vehicles with current characteristics, such as smart technologies, lightweight materials, and improved safety components, may appeal to more affluent customers. Automotive plastics play a significant role in the integration of these characteristics, which contributes to market growth. Electric and hybrid vehicles are becoming more affordable to people with more disposable income.

Despite the benefits of lightweight and versatile automotive plastics, cost remains an issue. Some high-performance polymers are more expensive than conventional materials, making widespread adoption challenging for manufacturers. Metals, for example, may still outperform plastics in terms of strength and durability, especially in certain applications like structural components. It is vital to overcome these performance discrepancies if automotive plastics are to be widely used. The automotive plastics market is vulnerable to supply chain disruptions such as fluctuations in raw material prices, geopolitical crises, and natural disasters. These disruptions can disrupt production plans and increase costs for businesses. Manufacturing automotive plastics can be complicated and necessitates specialised equipment.

Insights by Type

The polypropylene segment accounted for the largest market share over the forecast period 2023 to 2033. Polypropylene is a more cost-effective material when compared to other polymers and conventional materials such as metals. Its low cost makes it desirable to automakers seeking cost-effective alternatives without losing performance. Because of its great impact resistance, polypropylene is perfect for usage in automotive interiors and exteriors. Its impact resistance increases the durability and safety of numerous components. As electric vehicles gain popularity, so does the demand for lightweight materials in battery components. Because of its lightweight and long-lasting characteristics, polypropylene is an excellent choice for certain EV components.

Insights by Application

The interior segment accounted for the largest market share over the forecast period 2023 to 2033. Because of the growing popularity of electric vehicles, new interior design considerations have emerged. Plastics play an important role in the development of lightweight and innovative interior components for electric vehicles such as battery electric vehicles (BEVs) and hybrid electric vehicles (HEVs). Interior components made of lightweight polymers help to reduce vehicle weight. This is an important consideration for automakers aiming to enhance fuel efficiency while meeting regulatory standards. The incorporation of novel features and technology in vehicle interiors, such as touchscreens, infotainment systems, and smart connection, mandates the use of adaptable materials. Plastics offer the versatility needed for the seamless integration of multiple technologies.

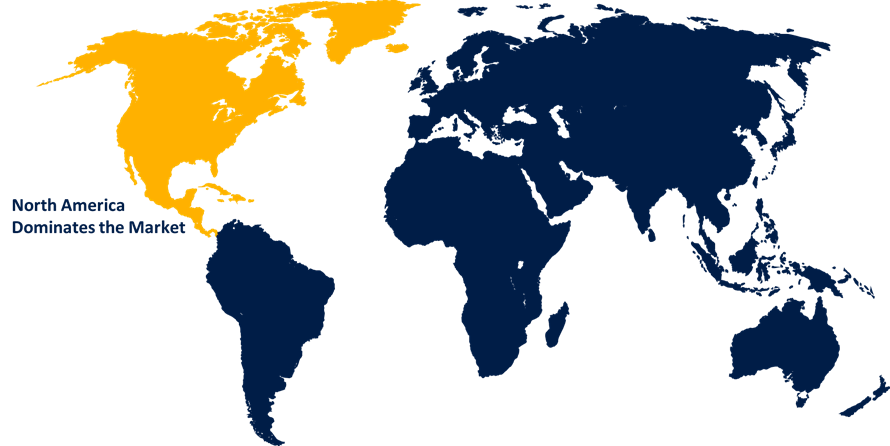

Insights by Region

Get more details on this report -

North America is anticipated to dominate the Automotive Plastics Market from 2023 to 2033. Lightweighting trends, fuel efficiency rules, and technological advancements in the automotive industry have all contributed to market growth. In North America, rising interest in and adoption of electric vehicles pushes up demand for lightweight materials such as automotive plastics. Plastics are used in the production of electric vehicle components, interiors, and battery casings. North America is home to several major automobile manufacturers and plastics suppliers. The competitive landscape is characterised by innovation, with firms seeking to develop and produce high-performance polymers for a wide range of automotive applications.

Asia Pacific is witnessing the fastest market growth between 2023 to 2033. The Asia Pacific region is a major automotive manufacturing hub, and the industry is continuously expanding. This expansion has considerably increased demand for automotive plastics as manufacturers seek lightweight and cost-effective materials. Asia Pacific contributes significantly to global automobile production. The sheer volume of vehicle production in countries such as China, Japan, and India has a direct impact on demand for automotive plastics for interiors, exteriors, and under-the-hood components. Electric and hybrid vehicles are gaining popularity in the region.

Recent Market Developments

- In May 2021, Covestro AG has introduced a new recycled polyethylene terephthalate. 3D pellet printing with recycled PET has been tested.

Major players in the market

- Momentive Performance Materials

- Hexion Inc.

- Arkema Group

- The Dow Chemical Company

- BASF SE

- LyondellBasell Industries Holdings B.V

- Evonik Industries

- Saudi Basic Industries Corporation (SABIC)

- Hanwha Group

- DuPont De Nemours, Inc.

Market Segmentation

This study forecasts revenue at global, regional, and country levels from 2023 to 2033.

Automotive Plastics Market, Type Analysis

- ABS

- Polyamide

- Polypropylene

Automotive Plastics Market, Application Analysis

- Interior

- Exterior

- Under bonnet

Automotive Plastics Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- South America

- Brazil

- Argentina

- Colombia

- Middle East & Africa

- UAE

- Saudi Arabia

- South Africa

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?