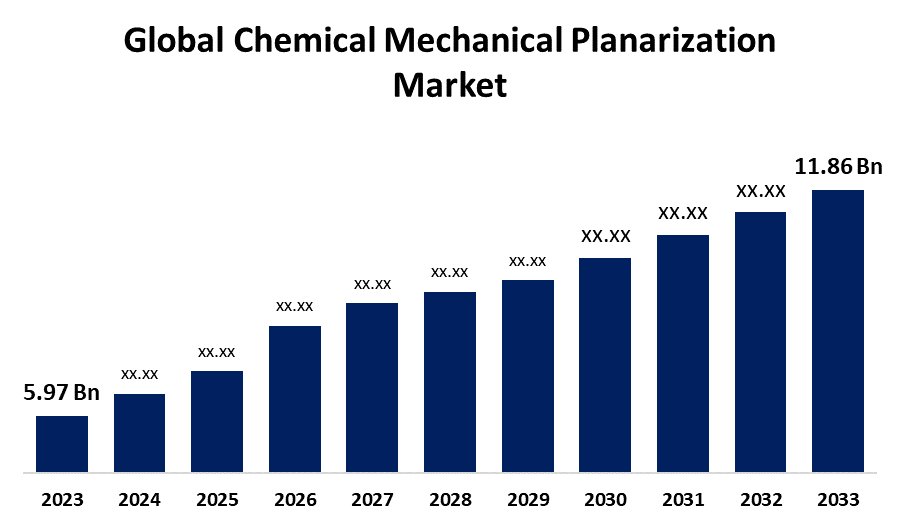

Global Chemical Mechanical Planarization Market Size To Worth USD 11.86 Billion by 2033 | CAGR of 7.11%

Category: Chemicals & MaterialsGlobal Chemical Mechanical Planarization Market Size To Worth USD 11.86 Billion by 2033

According to a research report published by Spherical Insights & Consulting, the Global Chemical Mechanical Planarization Market is to Grow from US 5.97 Billion in 2023 to USD 11.86 Billion by 2033, at a Compound Annual Growth Rate (CAGR) of 7.11% during the projected period.

Get more details on this report -

Browse key industry insights spread across 222 pages with 115 Market data tables and figures & charts from the report on the "Global Chemical Mechanical Planarization Market Size, Share, and COVID-19 Impact Analysis, By Equipment (Polishing & Grinding, Slurry Testing, Laboratory), By Consumables (Slurry, Pad Conditioners), By Application (Integrated Circuits, Optics, Compound Semiconductors, MEMS & NEMS), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2023 – 2033." Get Detailed Report Description Here: https://www.sphericalinsights.com/reports/chemical-mechanical-planarization-market

Chemical mechanical planarization, or CMP, is the process of planarizing and smoothing surfaces, which usually consist of two or more separate materials. Local planarization is the process of modifying the height differences between adjacent structures; global planarization is the process of modifying the height differences throughout the entire substrate surface. The sole method available for achieving global planarization is CMP surface processing. CMP is a common tool used in the semiconductor industry to planarize thin sheets. Treatable materials include dielectrics, polysilicon, and metals. Polished surfaces are of superior quality. The CMP technique was initially created to planarize silica, the most often used dielectric material. As the need for processing power in microelectronic devices grows, more sophisticated CMP procedures are being implemented. This is because sophisticated materials, such as polymeric dielectrics and metal interconnects like Cu and Ge, are being employed in radio frequency (RF), automotive technologies, and photovoltaics applications where efficiency and frequency are crucial. However, reducing errors in various CMP techniques could stop the market's growth.

The segment with the largest market share is polishing and grinding.

Based on equipment, the chemical mechanical planarization is divided into polishing & grinding, slurry testing, and laboratory. Among these, the segment with the largest market share is polishing and grinding. It is projected that the polishing and grinding equipment industry can lead the worldwide market. Under realistic and economical working conditions, the aim of chemical mechanical paired grinding is to greatly eliminate flaws. Chemical mechanical polishing is used to remove material and achieve very high planarities. By employing chemical oxidation and mechanical abrasion, it polishes semiconductor wafers or any other substrate. Many industries employ grinding and polishing technologies, which increase the value of products. In addition to conventional processing techniques, many types of polishing and grinding processes have been developed and implemented in industrial settings.

The market expansion could be bolstered by the spike in demand for the slurry segment.

Based on consumables, the chemical mechanical planarization is divided into slurry and pad conditioners. Among these, the market expansion could be bolstered by the spike in demand for the slurry segment. The industry with the largest predicted share of the worldwide market is Slurry. Slurries are liquid dispersions containing active chemicals and micro-abrasive grains that are employed in chemical mechanical planarization. Typically, they consist of a nanopowder abrasive combined with a chemically reacting fluid. Chemical etching softens the material, but mechanical abrasion removes it, smoothing the surface and flattening the topographic features. CMP pads and slurries are mixed and frequently applied to a polishing tool during the compound semiconductor fabrication process in order to planarize both die-level and wafer-level topography.

The segment with the biggest market share during the course of the forecast period is integrated circuits.

Based on application, the chemical mechanical planarization is divided into integrated circuits, optics, compound semiconductors, MEMS & NEMS. Among these, the segment with the biggest market share during the course of the forecast period is integrated circuits. In the semiconductor and microelectronics sectors, integrated circuits are now a distinct field. They are composed of extremely dense arrays on tiny semiconducting substrates, comprising hundreds to millions of discrete electrical elements. For many years, silicon (Si) and, to a lesser extent, gallium arsenide (GaAs) have been the main materials used in microelectronic substrates, even though intensive research and development has yielded a large number of innovative semiconductors suitable for the production of integrated circuits. Although integrated circuits are actually substrate materials extracted from semiconductor ingots, the term "chip" is commonly used to refer to them.

North America is having the biggest share of the global chemical mechanical planarization market over the forecast period.

Get more details on this report -

North America's substantial R&D spending provides it a competitive edge in the development of next-generation semiconductor technologies. The present circumstances are increasing the need for CMP technologies, which are necessary to produce semiconductor wafers with a high degree of consistency and precision. Furthermore, North America's position as a major hub for semiconductor manufacturing is cemented by government regulations and infrastructure assistance. Due to its propensity for adopting new technologies and expanding its market into other high-tech industries, the region has been a significant player in the growth of the global CMP market.

Asia-Pacific is predicted to grow fastest pace throughout the forecast period. As Asia-Pacific's capability for producing semiconductors increases, so does the requirement for CMP technologies to guarantee high yields and quality in semiconductor wafers. Because of its talented workforce, infrastructure investments, and advantageous government policies, the region is more appealing for the fabrication of semiconductors. As a result, Asia-Pacific is being known as the CMP market area growing at the fastest rate, which is encouraging competitiveness and innovation in the global semiconductor industry.

Major vendors in the global chemical mechanical planarization market include, Lam Research Corporation, Intel Corporation, Samsung Electronics Co., Ltd, Micron Technology, Inc, Taiwan Semiconductor Manufacturing Company Limited, Okamoto Machine Tool Works, Ltd, Alpsitec SAS, Axus Technology, Revasum, GlobalFoundries Inc, Hitachi Chemical Co., Ltd, Ebara Corporation, Versum Materials, Inc, DuPont Electronic Solutions, BASF SE, and Others.

Recent Developments

- In July 2022, with the addition of the range of products from CMC Materials, Entegris now offers the broadest portfolio in the industry together with enhanced operating capabilities for applications in the semiconductor ecosystem and in the fab environment.

Key Target Audience

- Market Players

- Investors

- End-users

- Government Authorities

- Consulting And Research Firm

- Venture capitalists

- Value-Added Resellers (VARs)

Market Segment

This study forecasts revenue at global, regional, and country levels from 2020 to 2033. Spherical Insights has segmented the global chemical mechanical planarization market based on the below-mentioned segments:

Global Chemical Mechanical Planarization Market, By Equipment

- Polishing & Grinding

- Slurry Testing

- Laboratory

Global Chemical Mechanical Planarization Market, By Consumables

- Slurry

- Pad Conditioners

Global Chemical Mechanical Planarization Market, By Application

- Integrated Circuits

- Optics

- Compound Semiconductors

- MEMS & NEMS

Global Chemical Mechanical Planarization Market, By Regional

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?