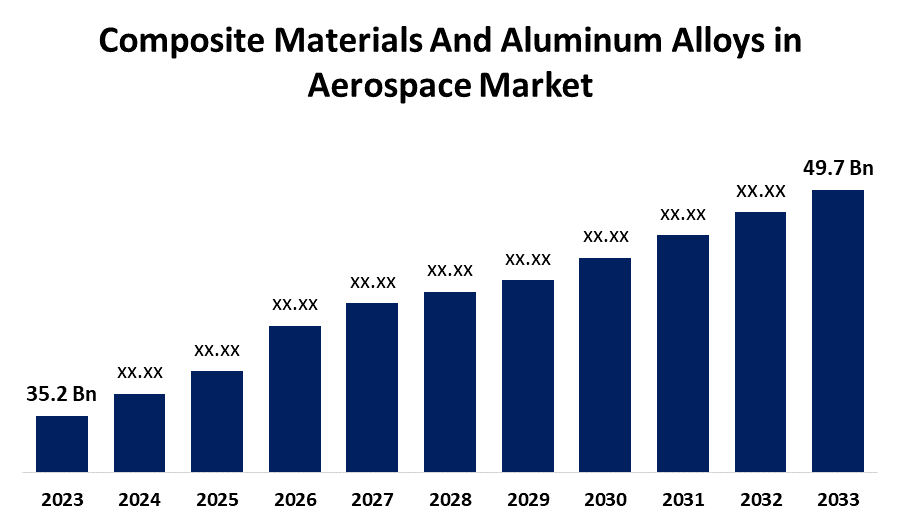

Global Composite Materials And Aluminum Alloys in Aerospace Market Size to Worth USD 49.7 Billion by 2033 | CAGR of 3.51%

Category: Aerospace & DefenseGlobal Composite Materials And Aluminum Alloys in Aerospace Market Size to Worth USD 49.7 Billion by 2033

According to a research report published by Spherical Insights & Consulting, the Global Composite Materials And Aluminum Alloys in Aerospace Market Size to grow from USD 35.2 billion in 2023 to USD 49.7 billion by 2033, at a Compound Annual Growth Rate (CAGR) of 3.51% during the forecast period.

Get more details on this report -

Browse key industry insights spread across 250 pages with 125 Market data tables and figures & charts from the report on the "Global Composite Materials And Aluminum Alloys in Aerospace Market Size, Share, and COVID-19 Impact Analysis, By Type (Aluminum Alloys, Titanium Alloys, Steel Alloys, Composites), By Application (Commercial Aircraft, Military Aircraft, Helicopters, Business and General Aviation, and Others), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2023 - 2033." Get Detailed Report Description Here: https://www.sphericalinsights.com/reports/composite-materials-and-aluminum-alloys-in-aerospace-market

The aerospace market is increasingly adopting composite materials and aluminum alloys for their beneficial properties, such as lightweight construction and high strength, essential for improving fuel efficiency and aircraft performance. Composites, including carbon fiber reinforced polymers, provide outstanding strength-to-weight ratios and resistance to corrosion, making them well-suited for contemporary aircraft designs. At the same time, aluminum alloys remain essential due to their cost-effectiveness and ease of manufacturing. The rising demand for fuel-efficient and environmentally friendly aircraft is driving innovation in these materials. Furthermore, advancements in manufacturing processes and a focus on sustainability are promoting the development of hybrid materials, broadening the applications of composites and aluminum alloys in the aerospace sector and ultimately contributing to safer and more efficient aviation solutions.

Composite Materials And Aluminum Alloys in Aerospace Market Value Chain Analysis

The value chain analysis of composite materials and aluminum alloys in the aerospace market consists of several critical stages. It starts with raw material sourcing, where suppliers provide essential components like carbon fibers, resins, and aluminum alloys. The subsequent stage is material processing, where these inputs are converted into usable forms using methods such as pultrusion, molding, and casting. Following this, manufacturers employ advanced engineering and design techniques to develop aircraft components, prioritizing weight reduction and structural integrity. The assembly stage brings these components together into aircraft, emphasizing quality assurance and compliance with regulations. Finally, distribution and aftermarket services ensure the efficient delivery of these materials and components to OEMs and MROs. This integrated approach fosters collaboration and innovation, ultimately supporting the growth and sustainability of the aerospace industry.

Composite Materials And Aluminum Alloys in Aerospace Market Opportunity Analysis

The aerospace market offers considerable opportunities for composite materials and aluminum alloys, driven by shifting industry trends. The increasing demand for fuel-efficient aircraft is leading manufacturers to seek lighter materials, with composites providing a significant advantage due to their excellent strength-to-weight ratios. The growth of sustainable aviation practices is further encouraging the use of eco-friendly composites, as regulatory frameworks increasingly emphasize environmental sustainability. Moreover, advancements in manufacturing technologies, such as 3D printing and automated fiber placement, are improving the production efficiency of these materials. The rising interest in electric and hybrid aircraft also boosts the demand for lightweight components. Additionally, the expansion of the aerospace sector in emerging markets opens new growth avenues, positioning composite materials and aluminum alloys as vital for future aviation innovations.

As manufacturers develop next-generation aircraft, they focus on weight reduction, fuel efficiency, and enhanced structural integrity. Composites like carbon fiber reinforced polymers deliver outstanding strength-to-weight ratios, enabling the production of lighter, more efficient aircraft. At the same time, advanced aluminum alloys provide superior durability and corrosion resistance, which are essential in the challenging aerospace environment. These materials support innovative designs, facilitating aerodynamic enhancements and reduced drag. Furthermore, the integration of composites and aluminum alloys assists manufacturers in meeting environmental regulations, as lighter aircraft lead to lower emissions. Overall, the synergy of these advanced materials is crucial in shaping the future of aerospace engineering.

One major challenge is the high cost of raw materials and manufacturing processes, which can hinder widespread adoption, particularly for smaller manufacturers. Additionally, the complexity of working with composites necessitates specialized skills and advanced technologies, potentially leading to skill shortages in the workforce. Quality control and testing procedures for composite materials tend to be more stringent than those for traditional metals, raising concerns regarding certification and compliance. Moreover, the repair and recycling of composite materials present difficulties due to their unique characteristics, complicating maintenance and end-of-life management. Lastly, the fluctuating prices of aluminum alloys and raw materials can affect budgeting and project feasibility, adding another layer of complexity to aerospace manufacturing.

Insights by Type

The aluminium alloys segment accounted for the largest market share over the forecast period 2023 to 2033. As aircraft manufacturers aim to improve fuel efficiency and lower emissions, advanced aluminum alloys are increasingly being employed in airframes, wings, and other essential components. These alloys provide a blend of strength, durability, and corrosion resistance, making them well-suited for contemporary aerospace applications. Furthermore, innovations in alloy formulations and manufacturing techniques are broadening their application in next-generation aircraft. The growing emphasis on cost-effective solutions, coupled with strong demand from emerging markets, is driving the segment’s expansion. As the aerospace industry progresses, the versatility and performance of aluminum alloys will be crucial in advancing sustainable aviation goals and enhancing overall aircraft performance.

Insights by Application

The commercial aircraft segment accounted for the largest market share over the forecast period 2023 to 2033. As airlines work to lower operational costs, manufacturers are increasingly integrating lightweight composite materials and advanced aluminum alloys into aircraft designs. Composites, such as carbon fiber reinforced polymers, provide exceptional strength-to-weight ratios, allowing for significant weight reductions and enhanced fuel efficiency. Meanwhile, aluminum alloys remain essential due to their durability and ease of fabrication. The rise of low-cost carriers and the growth of air travel in emerging markets are further driving the demand for new commercial aircraft. Additionally, advancements in manufacturing technologies are improving production processes, leading to faster delivery times and bolstering the segment's expansion in the global aerospace market.

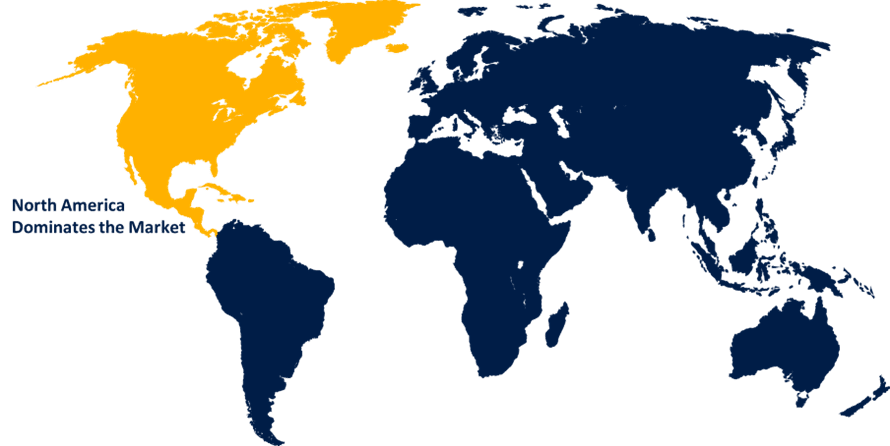

Insights by Region

Get more details on this report -

North America is anticipated to dominate the Composite Materials And Aluminum Alloys in Aerospace Market from 2023 to 2033. The region hosts major aircraft manufacturers like Boeing and Airbus, which are increasingly adopting advanced materials to improve fuel efficiency and lower emissions. The growing focus on lightweight designs is driving demand for composites, such as carbon fiber reinforced polymers, widely used in both commercial and military aircraft. Furthermore, North America benefits from a strong supply chain and advanced manufacturing technologies that promote innovation in material development. Government initiatives that support research and development, alongside investments in sustainable aviation, are also fueling market growth. Additionally, the region's strategic emphasis on aerospace defense and the rising demand for next-generation aircraft highlight the essential role of composite materials and aluminum alloys in North America's aerospace sector.

Asia Pacific is witnessing the fastest market growth between 2023 to 2033. Driven by rising demand for air travel and the expansion of airline fleets, countries are making significant investments in aerospace manufacturing and R&D. Composites, recognized for their lightweight nature and high strength, are being incorporated into both commercial and military aircraft to enhance fuel efficiency and minimize environmental impact. Furthermore, the region's increasing focus on domestic aircraft production has spurred advancements in material technologies. Collaboration between international manufacturers and local suppliers is also strengthening the supply chain and production capabilities. Government backing for aerospace initiatives, combined with growing disposable incomes and urbanization, further increases the demand for advanced materials, establishing Asia-Pacific as a key player in the global aerospace industry.

Recent Market Developments

- On February 2022, Sovay has pledged to increase its PVDF production capacity in Europe to address the rising demand for electric vehicle (EV) batteries.

Major players in the market

- Spirit AeroSystems

- General Dynamics

- Hexcel Corporation

- Safran

- Lockheed Martin

- Solvay

- Cytec Industries

- L3Harris Technologies

- Airbus

- Raytheon Technologies

- Boeing

- Toray Industries

- Dassault Aviation

- Northrop Grumman

- Alcoa Corporation

Market Segmentation

This study forecasts revenue at global, regional, and country levels from 2023 to 2033.

Composite Materials And Aluminum Alloys in Aerospace Market, Type Analysis

- Aluminum Alloys

- Titanium Alloys

- Steel Alloys

- Composites

Composite Materials And Aluminum Alloys in Aerospace Market, Application Analysis

- Commercial Aircraft

- Military Aircraft

- Helicopters

- Business and General Aviation

- Others

Composite Materials And Aluminum Alloys in Aerospace Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?