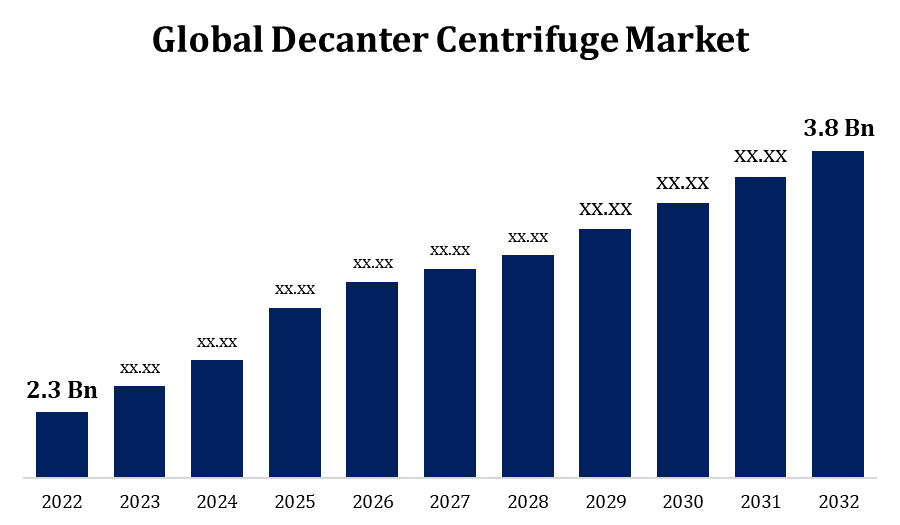

Global Decanter Centrifuge Market Worth USD 3.8 Billion by 2032 | CAGR Of 5.6%

Category: Machinery & EquipmentGlobal Decanter Centrifuge Market worth USD 3.8 Billion by 2032

According to a research report published by Spherical Insights & Consulting, the Global Decanter Centrifuge Market Size to grow from USD 2.3 Billion in 2022 to USD 3.8 Billion by 2032, at a Compound Annual Growth Rate (CAGR) of 5.6% during the forecast period.

Get more details on this report -

Browse key industry insights spread across 200 pages with 110 Market data tables and figures & charts from the report on the "Global Decanter Centrifuge Market Size By Design Type (Horizontal, Vertical), By Application (Waste Water Treatment, Oil/Gas Exploration and Petrochemical Industry, Food and Beverages, Mining and Metal Processing, Chemical, Pharmaceutical and Biotechnology, Pulp and Paper, Polymer Industry, Water Purification and Others), By Region, And Segment Forecasts, By Geographic Scope And Forecast". Get Detailed Report Description Here: https://www.sphericalinsights.com/reports/decanter-centrifuge-market

The decanter centrifuge market has expanded rapidly in recent years. The demand for efficient and cost-effective separation technology across industries has been a main driving. As environmental regulations become more stringent, industries are investing in technologies such as decanter centrifuges for wastewater treatment and sludge dewatering. Decanter centrifuges are used in the oil and gas industry to separate solids from drilling mud and wastewater, which contributes to the market's overall growth. In the food processing sector, these devices are used to separate particles from liquids in procedures such as juice extraction and oil clarification.

Decanter Centrifuge Market Value Chain Analysis

Suppliers of raw materials such as metals, polymers, and other components required for the manufacture of decanter centrifuges. Companies that design and build decanter centrifuges. This covers the design, construction, and testing of the machinery. Distributors are sales channels that connect producers with end users. Examples include wholesalers, retailers, and direct sales to industries. Decanter centrifuges are used in a range of industries, including wastewater treatment, oil and gas processing, food and beverage production, medicines, and so on. Companies that offer decanter centrifuge maintenance, repair, and support services to ensure peak performance for the life of the machine. Waste created during the separation process may be further processed or recycled in fields such as wastewater treatment.

Decanter Centrifuge Market Opportunity Analysis

Examine opportunities in emerging markets where industrialization is accelerating. These areas may experience an increase in demand for decanter centrifuges across a wide range of industries. Examine opportunities in emerging markets where industrialization is accelerating. These areas may experience an increase in demand for decanter centrifuges across a wide range of industries. Collaborate with other companies or research institutions to exploit complimentary technology. Partnerships can lead to the development of integrated solutions as well as the expansion of market reach. To build long-term client relationships, develop substantial after-sales services and maintenance contracts. Continuous assistance can increase consumer pleasure and loyalty. Decanter centrifuge systems should incorporate digital technologies and data analytics. This data can be utilised to improve predictive maintenance, general performance, and efficiency.

Decanter centrifuges are particularly successful at separating solid particles from liquid, making them invaluable in process industries where such separation is crucial. Particle removal from liquids is beneficial to businesses such as medicine, chemicals, and food and beverage. The global expansion of process industries is increasing demand for technology that can improve production efficiency. Decanter centrifuges satisfy the demands of expanding industrialization by providing a scalable and versatile solution for a wide range of industrial applications. Decanter centrifuges are used to separate solids from drilling mud and effluent in the oil and gas industry. Decanter centrifuges are in high demand in this sector as exploration and extraction activities continue.

The initial cost of obtaining and installing decanter centrifuges could be substantial. For smaller businesses or industries with limited resources, this first investment may be tough. Decanter centrifuges are efficient, but they must be repaired on a regular basis to maintain top performance. Maintenance costs can quickly build up, and firms must account for them in their operating budgets. Decanter centrifuge operation can be sophisticated, necessitating the use of trained personnel for setup, monitoring, and maintenance. Some industries may struggle to train and retain skilled workers. Decanter centrifuges can be very energy-intensive, especially when processing large amounts of material. More energy-efficient centrifuge designs are necessary as energy costs rise and environmental concerns grow.

Insights by Design Type

The horizontal type segment accounted for the largest market share over the forecast period 2023 to 2032. Horizontal decanter centrifuges are well-known for their flexibility to adapt to a wide range of materials and applications. They may efficiently separate solids from liquids in industries like as wastewater treatment, food and beverage, chemicals, and oil and gas. Horizontal decanter centrifuges are designed to run continuously, ensuring a consistent and continuous separation process. This quality is highly prized in businesses where continuous manufacturing is crucial for efficiency. The horizontal form allows for high throughput and processing capacity. Horizontal decanter centrifuges are ideal for applications that require large amounts of material to be processed efficiently. For conditions needing effective solids discharge, the horizontal shape is typically favoured. The design enables good separation of separated solids, which improves total efficiency.

Insights by Application

The chemical segment accounted for the largest market share over the forecast period 2023 to 2032. In chemical processes, it is customary to handle mixtures comprising solid particles suspended in liquid. Decanter centrifuges are crucial for quickly separating these components and ensuring the required purity and quality of the chemical output. Decanter centrifuges serve in the acceleration of chemical manufacturing operations. They enable continuous and effective phase separation, reducing the need for additional processing stages and increasing overall manufacturing efficiency. Decanter centrifuges are employed in chemical industry operations such as the separation of APIs (Active Pharmaceutical Ingredients), the purification of chemical compounds, and the manufacture of high-purity chemicals. In the polymer processing business, decanter centrifuges are used to extract polymer solids from liquid monomers or solvents.

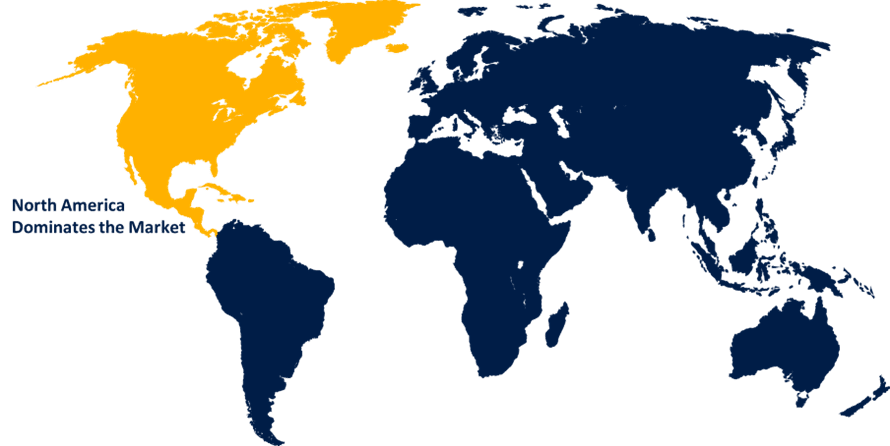

Insights by Region

Get more details on this report -

North America is anticipated to dominate the Decanter Centrifuge Market from 2023 to 2032. Decanter centrifuges are employed in the North American oil and gas sector for a variety of purposes, including the separation of solids from drilling mud and effluent. The continued exploration and production of oil and gas in the region adds to the demand for decanter centrifuges. Decanter centrifuges are used in the food and beverage industry in North America to clear liquids, extract oils, and separate particles from various food processing streams. The industry's emphasis on quality and efficiency drives the implementation of enhanced separation technology. Decanter centrifuges are employed in the pharmaceutical and chemical industries in North America for operations such as the separation of chemical compounds, the purification of pharmaceutical goods, and the recovery of precious materials.

Asia Pacific is witnessing the fastest market growth between 2023 to 2032. Rising industrialization and infrastructure development in nations such as China and India are driving demand for effective separation technologies. Decanter centrifuges are utilised in many industries, including wastewater treatment, mining, food and beverage, and many more. As the rate of urbanisation increases, so does the demand for wastewater treatment solutions. Decanter centrifuges play an important role in the effective separation of solids from wastewater, hence meeting the increasing demand for environmentally sustainable and efficient water management solutions. Decanter centrifuges are used to dewater and separate mining slurries in the Asia-Pacific mining industry. The demand for solid-liquid separation technology remains high, owing to ongoing mining operations in Australia, Indonesia, and other countries.

Recent Market Developments

- In March 2022, Flottweg SE decanters for juice extraction were introduced. This device's key feature was its low cost juice extraction while keeping high product quality. This will allow the company to broaden its food and beverage solution portfolio.

Major players in the market

- GEA (Germany)

- Flottweg SE (Germany)

- Pieralisi (Italy)

- Alfa Laval (Sweden)

- ANDRITZ (Austria)

- SLB (US)

- IHI ROTATING MACHINERY ENGINEERING CO LTD (Japan)

- Mitsubishi Kakoki Kaisha, Ltd (Japan)

- Tomoe Engineering Co Ltd (Japan)

- Fismidth (Denmark)

Market Segmentation

This study forecasts revenue at global, regional, and country levels from 2023 to 2032.

Decanter Centrifuge Market, Design Type Analysis

- Horizontal

- Vertical

Decanter Centrifuge Market, Application Analysis

- Waste Water Treatment

- Oil/Gas Exploration and Petrochemical Industry

- Food and Beverages

- Mining and Metal Processing

- Chemical

- Pharmaceutical and Biotechnology

- Pulp and Paper

- Polymer Industry

- Water Purification

- Others

Decanter Centrifuge Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- South America

- Brazil

- Argentina

- Colombia

- Middle East & Africa

- UAE

- Saudi Arabia

- South Africa

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?