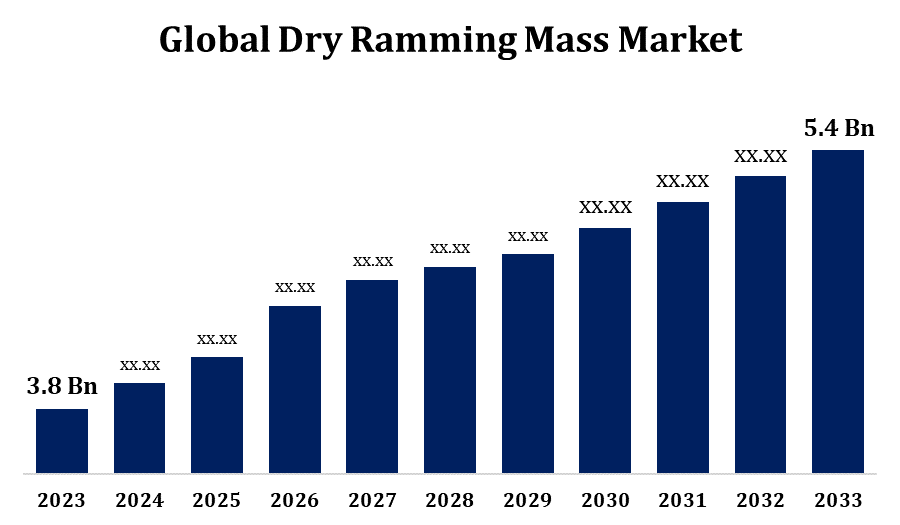

Global Dry Ramming Mass Market Size To Worth USD 5.4 Billion By 2033 | CAGR of 3.58%

Category: Chemicals & MaterialsGlobal Dry Ramming Mass Market Size To Worth USD 5.4 Billion By 2033

According to a research report published by Spherical Insights & Consulting, the Global Dry Ramming Mass Market Size to Grow from USD 3.8 Billion in 2023 to USD 5.4 Billion by 2033, at a Compound Annual Growth Rate (CAGR) of 3.58% during the forecast period.

Get more details on this report -

Browse key industry insights spread across 221 pages with 110 Market data tables and figures & charts from the report on the "Global Dry Ramming Mass Market Size, Share, and COVID-19 Impact Analysis, By Type (Alumina Ramming Mass, Silica Ramming Mass, Magnesia Based Ramming Mass and Others), By Application (Foundries, Blast Furnace, Electric Arc Furnace, Steel, Non steel and Others), By Function (Lining, Repairing, Patching and Others), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2023 - 2033." Get Detailed Report Description Here:https://www.sphericalinsights.com/reports/dry-ramming-mass-market

The dry ramming mass market is experiencing substantial growth, largely due to its expanding applications in the steel and non-ferrous metal industries. Made from refractory materials, dry ramming mass is crucial for lining induction furnaces, offering excellent thermal stability and durability against mechanical wear. This market is driven by the rising demand for high-efficiency furnaces and the pursuit of energy-efficient solutions in metal production. Key growth factors include rapid industrialization, the growth of the automotive and construction sectors, and strict regulations encouraging the use of eco-friendly materials. The Asia-Pacific region leads the market, supported by vigorous industrial activity, followed by North America and Europe. Additionally, innovations in product formulations and increased investments in research and development further bolster growth prospects.

Dry Ramming Mass Market Value Chain Analysis

The value chain of the dry ramming mass market consists of several critical stages, beginning with the sourcing of raw materials such as alumina and silica. These refractory materials are processed and blended to formulate the dry ramming mass, customized for specific applications. The manufacturing process includes mixing, granulating, and packaging the final product, with stringent quality control measures at each stage. Following manufacturing, distribution logistics manage the transportation of products to various end-users, including producers in the steel and non-ferrous metal industries. End-users utilize dry ramming mass in induction furnaces to achieve optimal performance. User feedback plays a crucial role in guiding manufacturers on performance enhancements and opportunities for innovation. Overall, effective collaboration among suppliers, manufacturers, and end-users is essential for improving product quality and addressing market needs.

Dry Ramming Mass Market Opportunity Analysis

The dry ramming mass market offers significant opportunities fueled by the rising demand for efficient and durable refractory materials across various industries. The increase in steel production, particularly in emerging economies, creates a strong market for dry ramming mass, which is crucial for induction furnaces. Furthermore, the shift towards energy-efficient and environmentally friendly manufacturing processes aligns with the advantages of dry ramming mass, enhancing thermal efficiency and lowering energy consumption. Innovations in product formulations can help overcome specific performance challenges, broadening market potential. Additionally, the growing use of advanced technologies in metal production, along with the expansion of the automotive and construction sectors, presents lucrative opportunities. Strategic partnerships and collaborations within the supply chain can further enhance market penetration and support sustainable growth.

The growth of the expanding steel industry is a significant driver for the dry ramming mass market. As global steel production continues to rise, the demand for high-performance refractory materials in induction furnaces is increasing. Dry ramming mass is essential for enhancing the efficiency and lifespan of these furnaces, offering excellent thermal resistance and reducing wear. The transition towards more efficient manufacturing processes and the emphasis on energy conservation further boost this demand, as dry ramming mass improves thermal management and lowers energy costs. Additionally, the growth of emerging economies, which are increasing their steel production capacities, creates further opportunities for market expansion. Overall, the alignment of growth in the steel industry with the dry ramming mass market presents a strong outlook for future development.

The dry ramming mass market encounters several challenges that could affect its growth trajectory. A primary concern is the volatility of raw material prices, which can influence production costs and profitability for manufacturers. Additionally, the rising emphasis on sustainability and the demand for eco-friendly materials present a challenge, as companies need to innovate and develop greener alternatives while maintaining performance standards. Competition from alternative refractory materials may also impede market growth, as technological advancements could result in the adoption of substitute products. Moreover, the complexity of manufacturing processes and the need for skilled labor can lead to operational challenges. Lastly, fluctuations in demand from the steel and non-ferrous metal industries, shaped by global economic conditions, can create uncertainty in market dynamics.

Insights by Type

The Alumina Ramming Mass segment accounted for the largest market share over the forecast period 2023 to 2033. Alumina-based formulations provide exceptional thermal resistance, mechanical strength, and corrosion protection, making them well-suited for use in induction furnaces and other high-temperature applications. As industries seek to improve efficiency and lower operational costs, the demand for alumina ramming mass is rising, particularly in steel and non-ferrous metal production. Furthermore, the shift towards energy-efficient manufacturing processes is boosting the adoption of alumina ramming mass, which enhances thermal management and decreases energy consumption. Ongoing technological advancements in alumina formulations are also broadening their application range, supporting the growth of this segment and establishing it as a favored choice among manufacturers in the dry ramming mass market.

Insights by Application

The foundries segment accounted for the largest market share over the forecast period 2023 to 2033. As foundries strive to improve production efficiency and minimize downtime, the use of high-quality dry ramming mass becomes crucial for optimal furnace performance. This material is essential for lining induction furnaces, providing exceptional thermal stability and wear resistance necessary for metal melting processes. The growth of the automotive, aerospace, and construction sectors is further increasing the demand for casting solutions, thereby enhancing the foundries segment. Additionally, technological advancements and the creation of innovative ramming mass formulations designed for specific applications make this segment even more appealing. Overall, the expansion of the foundries segment is expected to play a significant role in the overall growth of the dry ramming mass market.

Insights by Function

The lining segment accounted for the largest market share over the forecast period 2023 to 2033. As industries prioritize improving production efficiency and lowering maintenance costs, the demand for high-quality lining materials has increased significantly. Dry ramming mass offers outstanding thermal resistance, mechanical strength, and chemical resistance, making it an ideal option for furnace linings. The growth of the steel and non-ferrous metal industries, coupled with the expansion of foundries, is propelling this segment, as manufacturers seek dependable materials capable of withstanding harsh conditions. Additionally, continuous advancements in ramming mass formulations designed for specific applications are enhancing their performance, thereby contributing to the growth of the lining segment within the larger dry ramming mass market.

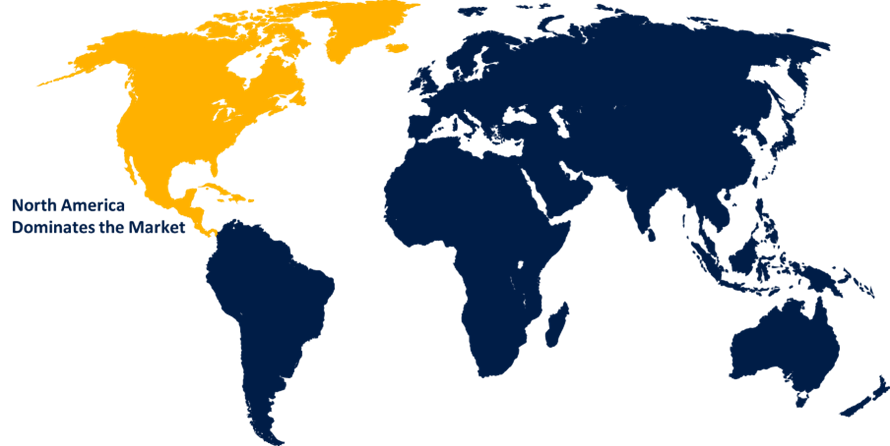

Insights by Region

Get more details on this report -

North America is anticipated to dominate the Dry Ramming Mass Market from 2023 to 2033. Key players in the region are concentrating on technological advancements and innovative formulations to improve product quality and performance. The presence of established steel manufacturers and foundries, especially in the United States, drives the demand for dry ramming mass, which is essential for efficient induction furnace operations. Additionally, stringent environmental regulations are promoting the use of eco-friendly refractory solutions, creating new opportunities for market growth. While challenges such as fluctuating raw material prices and competition from alternative refractory products persist, the North American market is positioned for growth, bolstered by industrial advancements and rising investments in infrastructure.

Asia Pacific is witnessing the fastest market growth between 2023 to 2033. Emerging nations are becoming major steel producers, driving up the demand for refractory materials used in induction furnaces. The region’s emphasis on improving production efficiency and energy conservation further accelerates the adoption of dry ramming mass, recognized for its outstanding thermal stability and durability. Moreover, the expanding automotive and construction industries are increasing the demand for non-ferrous metal applications. Although challenges such as fluctuating raw material prices and environmental regulations persist, the Asia-Pacific market is anticipated to experience significant growth, supported by ongoing infrastructure projects and investments in advanced manufacturing technologies.

Recent Market Developments

- On April 2023, AM/NS India has obtained approval from the National Company Law Tribunal (NCLT) in India to acquire Indian Steel Corporation. This acquisition aims to strengthen its downstream capabilities and broaden its product offerings.

Major players in the market

- Vesuvius

- Calderys

- HarbisonWalker International

- Magnesita Refratários S.A.

- Saint-Gobain

- RHI Magnesita

- Resco Products

- Minteq International Inc.

- Imerys Refractory Minerals

- Morgan Advanced Materials

Market Segmentation

This study forecasts revenue at global, regional, and country levels from 2023 to 2033.

Dry Ramming Mass Market, Type Analysis

- Alumina Ramming Mass

- Silica Ramming Mass

- Magnesia Based Ramming Mass

- Others

Dry Ramming Mass Market, Application Analysis

- Foundries

- Blast Furnace

- Electric Arc Furnace

- Steel

- Non steel

- Others

Dry Ramming Mass Market, Function Analysis

- Lining

- Repairing

- Patching

- Others

Dry Ramming Mass Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?