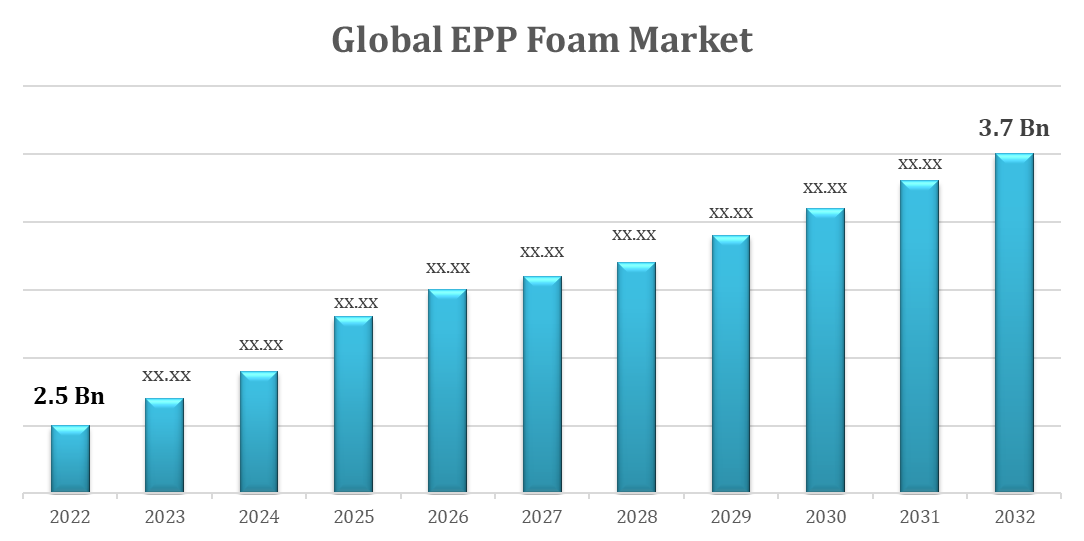

Global EPP Foam Market Size to Worth USD 3.7 Billion by 2032. | CAGR 12.1%

Category: Chemicals & MaterialsGlobal EPP Foam Market Size to Worth USD 3.7 Billion by 2032.

According to a research report published by Spherical Insights & Consulting, the Global EPP Foam Market Size to grow from USD 2.5 Billion in 2022 to USD 3.7 Billion by 2032, at a Compound Annual Growth Rate (CAGR) of 12.1% during the Forecast period.

Get more details on this report -

Browse key industry insights spread across 200 pages with 150 market data tables and figures & charts from the report on the "Global EPP Foam Market Size By Product (Low Density, Medium Density, High Density), By Application (Bumpers, Roof Pillars, Seat Bracing, Armrests, Others), By Region, And Segment Forecasts, By Geographic Scope And Forecast". Get Detailed Report Description Here : https://www.sphericalinsights.com/reports/epp-foam-market

The EPP foam market has been growing, and this trend is expected to continue. Due to its unique combination of lightweight construction, impact resistance, thermal insulation, and recyclability, the material is preferred by many industries. EPP foam is frequently used in the manufacturing of parts for automobiles, including bumpers, interior components, and safety features. Due to its ability to absorb energy following crashes, it increases vehicle safety. Due to its cushioning capabilities, EPP foam makes a great material for protective packaging. It is widely used to carry delicate and fragile goods in a safe manner. EPP foam is utilised in sports and leisure equipment like helmets, protective clothes, and even some sporting products because of its impact-absorbing properties.

EPP Foam Market Value Chain Analysis

The value chain begins with suppliers of raw materials, mainly polypropylene beads. These vendors provide the raw materials needed to produce EPP foam. EPP foam producers shape polypropylene beads to create expanded polypropylene foam. The beads must first be expanded with steam before being moulded into the desired forms. Businesses in the automotive, packaging, consumer goods, sports and leisure, construction, medical, and other sectors are among the end users of EPP foam products. They purchase EPP foam components to use in their many applications. The final link in the value chain is the person who will use the products made with or using EPP foam. At the end of a product's life cycle, there may be a recycling and waste management phase.

EPP Foam Market Price Analysis

The primary raw material used to make EPP foam, polypropylene beads, directly affects the price of manufacture. Polypropylene costs are subject to change, which may have an impact on the overall cost of EPP foam products. The complexity of the manufacturing process, which includes energy costs for steam expansion and moulding, labour costs, and overhead costs, has an impact on the entire cost structure. If specific upgrades or additives, such as flame retardants, colourants, or other upgrades, are incorporated into the EPP foam, the overall cost and future pricing may alter. The complexity of the design and the moulds used to produce EPP foam goods can have an impact on costs. More time and materials may be required to process drawings or moulds with more elaborate details.

The exceptional ability of EPP foam to absorb impact is well known. A major problem is the security of children's toys and recreational products. EPP foam is used to create protective components including helmet liners, padding for sporting equipment, and even toys to decrease the effects of falls and accidents. Toys and sporting products frequently require materials that are both lightweight and durable. The best choice is EPP foam. Due to its ability to offer the necessary strength without adding weight, it is ideal for items like toys and light athletic equipment. Toys and sporting products frequently require materials that are both lightweight and durable. The best choice is EPP foam.

Polypropylene, the primary material of EPP foam, has a price that is subject to market fluctuations. This volatility may affect the manufacturing costs for firms. EPP foam is in competition with other materials that possess equivalent or different properties. Business owners may select different foams, polymers, or even bio-based materials based on their own needs and preferences. The moulding process used in the production of EPP foam can require significant initial equipment investments. This entry barrier may limit the number of new businesses that can enter the market. While it is possible to recycle EPP foam, not all locations could have simple access to collection and recycling facilities. Different ways of disposal are available, and improper disposal may cause environmental problems.

Insights by Product

The high density segment accounted for the largest market share over the forecast period 2023 to 2032. High-density EPP foam is frequently used in the automotive industry for safety applications. Among other things, it's used to create bumper cores, energy-absorbing materials, and interior parts. The high density makes it possible for higher impact resistance and energy absorption, which contributes to increased vehicle safety. High-density EPP foam is utilised in industrial packaging applications where strength and protection are crucial. It is used to give bulky or delicate products packaging choices when they need the maximum level of impact resistance while being transported. In the medical industry, high-density EPP foam is utilised to wrap delicate medical equipment.

Insights by Application

Bumpers segment is witnessing the fastest market growth over the forecast period 2023 to 2032. The famed lightness of EPP foam is well known. In automotive applications where reducing vehicle weight is a priority for fuel economy, EPP foam is advised. Without significantly increasing the vehicle's weight, it provides the necessary impact resistance. Important safety features include vehicle bumpers, which are designed to deflect and disperse energy during collisions. Due to its ability to absorb impact energy and spread it across a larger surface area, EPP foam is particularly helpful in this application and helps to boost safety. Due to the globalisation of the automotive industry, particularly in regions with high production volumes, there is a greater demand for materials like EPP foam for bumpers.

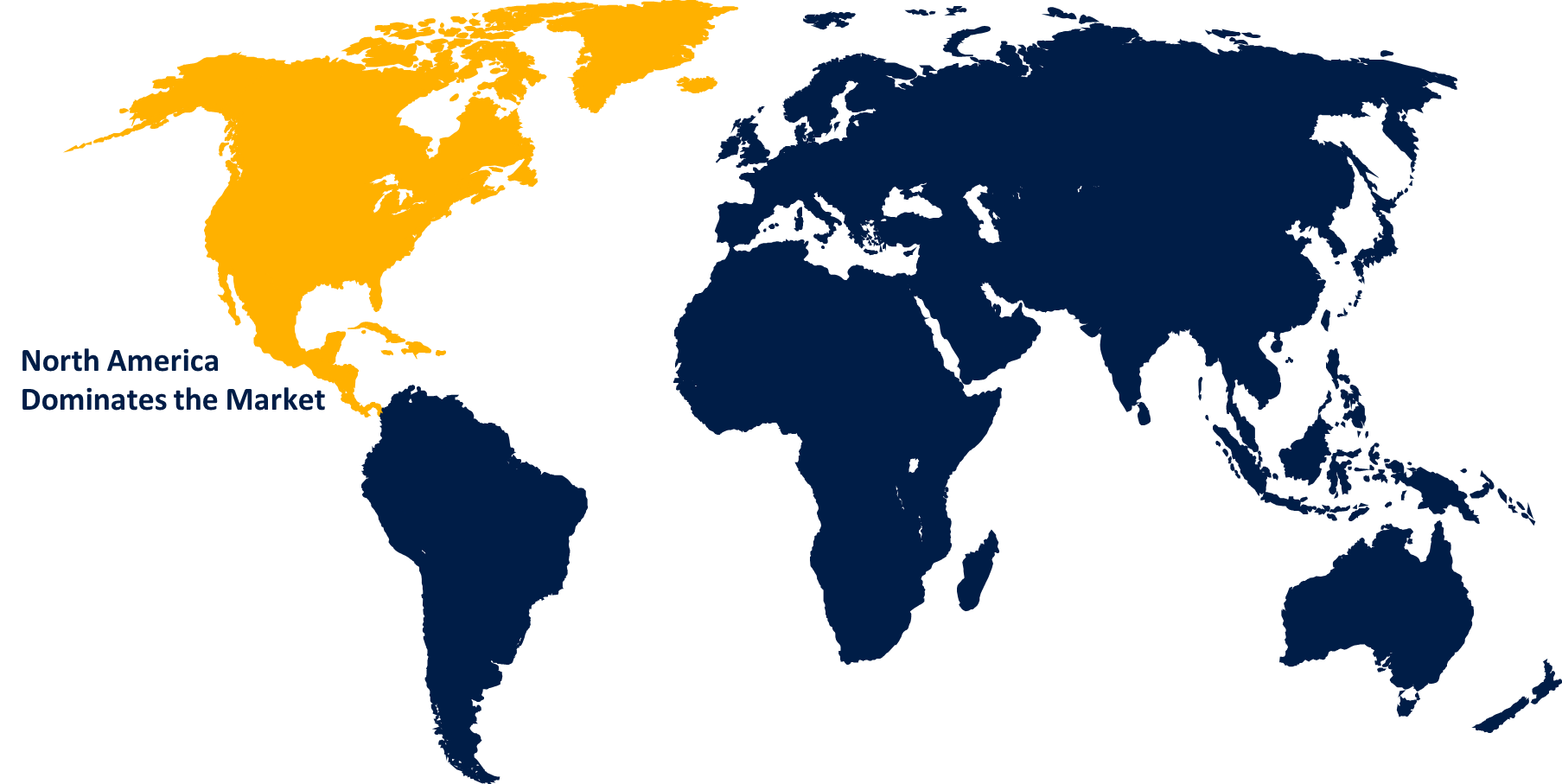

North America Market Statistics

Get more details on this report -

North America is anticipated to dominate the EPP Foam market from 2023 to 2032. EPP foam is widely used in the automobile sector in North America. EPP foam is used to construct several automobile components, including bumpers, interior fixtures, and safety systems. Its ability to absorb energy during collisions accounts for a substantial part of its importance in the automotive industry. EPP foam is frequently used for packaging in North America. Due to its small weight and cushioning capabilities, it is a fantastic choice for protecting delicate and valuable items during shipping. EPP foam is used in the creation of consumer goods and electronics. Because of its impact resistance and small weight, it can be used to make appliances and electrical equipment. In the medical sector, EPP foam is used to package delicate medical equipment.

Asia Pacific Market Statistics

Asia Pacific is witnessing the fastest market growth between 2023 to 2032. In the Asia-Pacific region, which includes countries like China, India, and Japan, industrialization has advanced quickly. The demand for goods like EPP foam, which is utilised in the packaging, automotive, and other industries, has increased as a result of this expansion. The Asia-Pacific automotive sector dominates the EPP foam market. EPP foam is often used in the production of automotive components due to its light weight and ability to absorb impact energy. The growing e-commerce business in Asia-Pacific has increased the demand for protective packaging materials. Due to its cushioning capabilities, EPP foam is ideal for ensuring the secure transit of goods.

Major players in the market

- JSP

- BASF SE

- KANEKA CORPORATION

- DS Smith

- FURUKAWA ELECTRIC CO. LTD.

- Hanwha Group

- Sonoco Products Company

- Knauf Industries

- Izoblok

- DONGSHIN INDUSTRY INCORPORATED

- Clark Foam Products Corporation

- Paracoat Products Ltd.

- Molan-Pino South Africa

- Signode Industrial Group LLC

- Armacel

Market Segmentation

This study forecasts revenue at global, regional, and country levels from 2023 to 2032.

EPP Foam Market, Product Analysis

- Low Density

- Medium Density

- High Density

EPP Foam Market, Application Analysis

- Bumpers

- Roof Pillars

- Seat Bracing

- Armrests

- Others

EPP Foam Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- South America

- Brazil

- Argentina

- Colombia

- Middle East & Africa

- UAE

- Saudi Arabia

- South Africa

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?