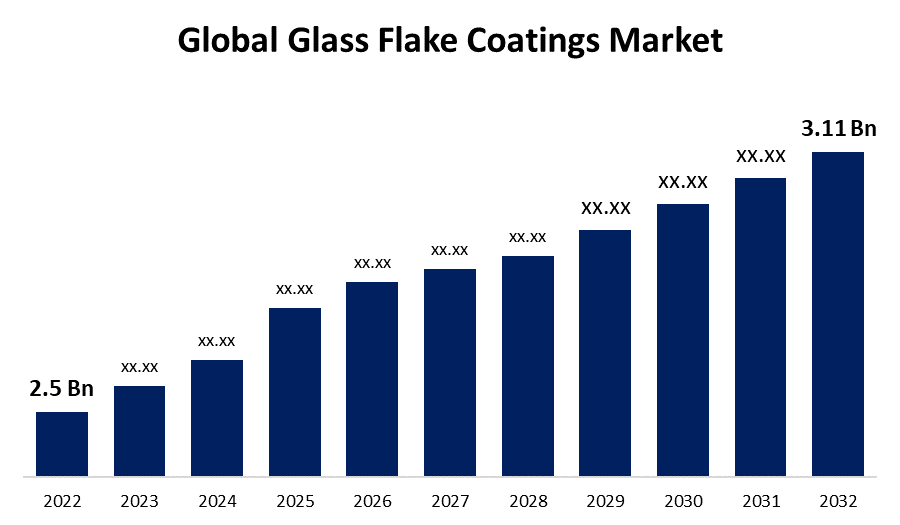

Global Glass Flake Coatings Market Size To Worth USD 3.11 Billion By 2032 | CAGR of 4.9%

Category: Chemicals & MaterialsGlobal Glass Flake Coatings Market Size To Worth USD 3.11 Billion By 2032.

According to a research report published by Spherical Insights & Consulting, the Global Glass Flake Coatings Market Size to grow from USD 2.5 Billion in 2022 to USD 3.11 Billion by 2032, at a Compound Annual Growth Rate (CAGR) of 4.9% during the forecast period.

Get more details on this report -

Browse key industry insights spread across 200 pages with 120 Market data tables and figures & charts from the report on the "Global Glass Flake Coatings Market Size, Share, and COVID-19 Impact, By Resin Type, By Substrate Type, By End-use, by Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2022 – 2032." Get Detailed Report Description Here: https://www.sphericalinsights.com/reports/glass-flake-coatings-market

Glass flake coatings are one type of protective coating that is used on a variety of products to provide excellent corrosion resistance and other protective properties. To make them, glass flakes—thin, flat bits of glass—are mixed with the coating substance. These glass flakes are typically made from different glass types, such as borosilicate, soda-lime, or E-glass, which have high mechanical strength and are resistant to chemical attack. Glass flake coatings work very well to protect substrates from corrosion caused by chemicals, moisture, and environmental exposure. They are thus especially useful in circumstances when protection from hazardous environments is essential. Because they can withstand prolonged exposure to ultraviolet (UV) radiation without significantly deteriorating, glass flake coatings are suitable for outdoor applications.

COVID 19 Impact

The raw materials and chemicals used in the coatings industry are sourced from a wide variety of suppliers worldwide. The pandemic may have had an impact on the supply chain, producing delays and shortages of crucial ingredients required to produce glass flake coatings. These effects may have included delays in transportation, industrial shutdowns, and border restrictions. The epidemic's lockdowns and economic slowdowns had an impact on industries like the automotive, aerospace, construction, and manufacturing. These industries consume a significant amount of coatings, notably glass flake coatings. Reduced demand in some industries may have had an effect on the overall market for coatings.

The necessity for efficient corrosion protection solutions in industries like oil and gas, maritime, chemical processing, and infrastructure has increased demand for glass flake coatings. High corrosion protection is provided by these coatings, extending the useful life of equipment, buildings, and other assets. Expanding infrastructure projects, particularly in developing countries, have raised the demand for protective coatings like glass flake coatings. Construction of bridges, pipelines, water treatment facilities, and other infrastructure requires dependable corrosion protection. Glass flake coatings are well known for their low permeability and chemical resistance, which can help contain hazardous substances and prevent environmental pollution. As environmental regulations tighten, it is more important than ever to utilise protective coatings that minimise environmental damage.

Glass flake coatings can be relatively expensive when compared to other types of protective coatings. Their higher price is due to the labor-intensive manufacturing method and the expensive raw materials, particularly premium glass flakes. This cost factor may limit their adoption, especially in industries where money is scarce. Glass flake coatings must be applied properly, which necessitates the use of qualified professionals and specific equipment. They must have a consistent thickness and coverage in order to function. Because of the possibility for improper application to result in coating flaws and reduced protection, some users may be deterred from utilising these coatings. Glass flake coatings need to be carefully prepared in order to provide excellent adherence to the substrate.

Resin Type Insights

Epoxy segment is dominating the market over the forecast period

On the basis of resin type, the global glass flakes coatings market is segmented into epoxy, vinyl ester, polyester. Among these, epoxy segment is dominating the market over the forecast period. Epoxy-based glass flake coatings are one of the most widely used options for corrosion prevention and other protective applications due to their exceptional mechanical, chemical, and adhesive properties. This broad use in a range of industries has resulted from these coatings' superior performance in these areas. Because they have excellent mechanical strength, abrasion resistance, and impact resistance, epoxy-based glass flake coatings are the best choice for demanding situations where surfaces are vulnerable to wear and tear. Many firms are subject to strict environmental and safety regulations. Since they may be modified to meet certain regulatory requirements, epoxy-based glass flake coatings are a popular choice for projects that demand adherence to rigorous standards.

Substrate Type Insights

Steel substrate segment holds the highest market share over the forecast period

Based on the substrate type, the global glass flakes coatings market is segmented into steel and concrete. Among these, steel substrate segment holds the highest market share over the forecast period. Steel is a crucial component in industries like oil and gas, maritime, chemical processing, infrastructure, and transportation. These sectors usually work in challenging environments where corrosion protection is crucial. The need for glass flake coatings on steel substrates has increased as a result in these industries. As infrastructure construction has increased, especially in developing countries, so has the demand for protective coatings on steel substrates. New construction projects in the transportation, water management, and energy sectors typically involve steel components that need to be corrosion-protected.

End Use Insights

Marine segment dominates the market over the forecast period

On the basis of end use, the global glass flakes coatings market is segmented into oil and gas, marine, chemical and petrochemical, others. Among these, marine segment dominates the market with the largest market share over the forecast period. Glass flake coatings are utilised in marine applications to help solve issues brought on by marine growth. These coatings create an impermeable, smooth surface that is resistant to growth and attachment by aquatic organisms. The capacity of glass flake coatings to withstand corrosion also protects the substrate against damage brought on by marine growth and saltwater exposure. The market for glass flake coatings has been growing as a result of increased demand from several sectors, including infrastructure, chemical processing, oil and gas, maritime, and oil and gas. Due to the rise in offshore exploration and production activities as well as the demand for corrosion protection in marine and coastal projects, the industry has expanded.

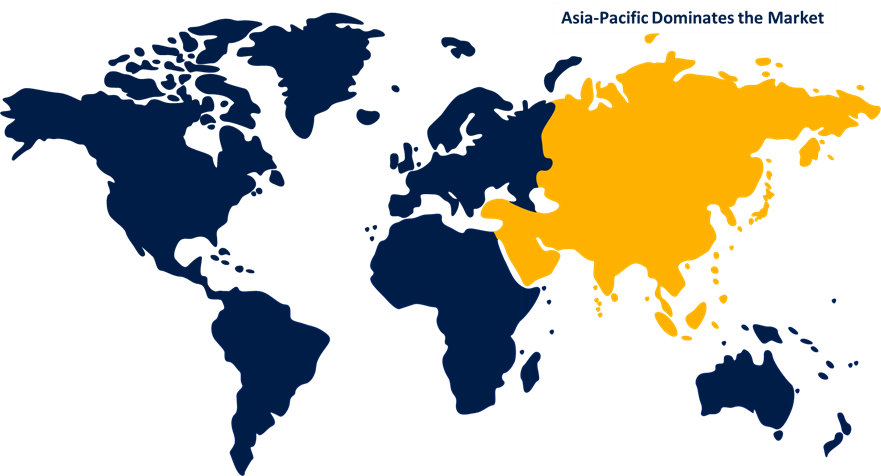

Regional Insights

Asia Pacific region holds the highest market share over the forecast period

Get more details on this report -

Asia Pacific is dominating the market with the highest market share over the forecast period. The region's expanding industrial and infrastructure sectors, which include shipbuilding, offshore oil and gas platforms, and chemical processing plants, have spurred the demand for high-performance coatings that offer corrosion protection and chemical resistance. The Asia Pacific region contains some of the world's busiest ports and maritime trade routes. Glass flake coatings are being used by ship owners and operators to protect their vessels from corrosion and marine growth while also reducing the cost of maintenance. The area's large offshore oil and gas resources have drawn increased attention to exploration and development activities. In such harsh marine environments, glass flake coatings are preferred to protect assets from corrosion and fouling.

North America is witnessing the fastest market growth over the forecast period. The established infrastructure of North America includes facilities for processing chemicals, building bridges, and operating power plants. The demand for high-tech protective coatings to protect and extend the life of these assets has propelled the market for glass flake coatings. The importance of sustainability and energy efficiency is rising in the North American coatings industry. Glass flake coatings can help shorten maintenance cycles, which lowers waste and energy use because of their enduring protective characteristics.

Market Segment

This study forecasts revenue at global, regional, and country levels from 2019 to 2032. Spherical Insights has segmented the global Glass Flake Coatings Market based on the below-mentioned segments:

Glass Flake Coatings Market, Resin Type Analysis

- Epoxy

- Vinyl ester

- Polyester

Glass Flake Coatings Market, Substrate Type Analysis

- Steel

- Concrete

Glass Flake Coatings Market, End Use Analysis

- Oil and gas

- Marine

- Chemical and petrochemical

- Others

Glass Flake Coatings Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of Middle East & Africa

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?