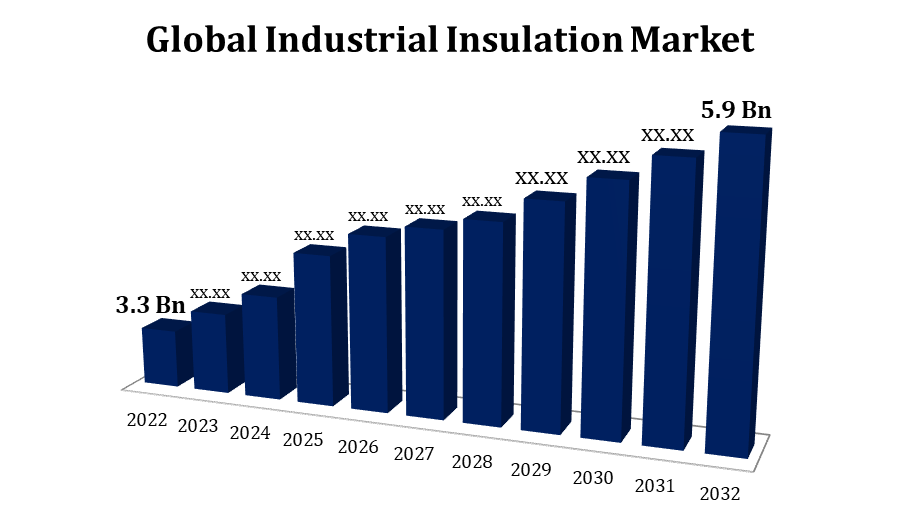

Global Industrial Insulation Market Size to Worth USD 5.9 Billion by 2032 | CAGR of 7.1%

Category: Advanced MaterialsGlobal Industrial Insulation Market Size to Worth USD 5.9 Billion by 2032

According to a research report published by Spherical Insights & Consulting, the Global Industrial Insulation Market Size to Grow from USD 3.3 Billion in 2022 to USD 5.9 Billion by 2032, at a Compound Annual Growth Rate (CAGR) of 7.1% during the forecast period.

Get more details on this report -

Browse key industry insights spread across 200 pages with 110 market data tables and figures & charts from the report on "Global Industrial Insulation Market Size By Form (Pipe, Blanket, Board), By Material (Mineral Wool, Calcium Silicate, Plastic foams), By End-Use Industry (Power, Oil & Gas, Cement), By Region, And Segment Forecasts, By Geographic Scope And Forecast 2022 - 2032." Get Detailed Report Description Here: https://www.sphericalinsights.com/reports/industrial-insulation-market

Industrial insulation makes use of a range of materials and techniques to reduce heat transport and maintain energy inside industrial facilities. The main goal is to create a thermal barrier that prevents heat from escaping, ensuring that processes and equipment operate at optimal efficiency. frequently used because of its adaptability, rust resistance, and heat stability. Pipes, boilers, and equipment are usually the topics. Constructed from natural or synthetic materials, it offers exceptional thermal insulation and fire protection. It is utilised in high-temperature applications. a robust, rigid insulator that is impervious to heat, moisture, and fire. It is often used in severe industrial conditions. Insulation for pipes and ducts reduces energy loss in transit by maintaining a constant temperature for fluids and air.

Industrial Insulation Market Value Chain Analysis

Raw materials used in industrial insulation include mineral wool, cellular glass, fibreglass, and foamed polymers. Suppliers of these commodities play a crucial role in the value chain. Manufacturers transform raw materials into insulating materials through processes including melting, spinning (for fibreglass), or shaping (for mineral wool). Insulation materials are transferred from production locations to distribution centres and finally to end users. Product quality preservation and timely delivery are dependent on efficient logistics management. Distributors and wholesalers function as intermediaries, supplying insulating materials to retailers, builders, and other end users. Insulating materials need to be handled and kept correctly to prevent damage and ensure the integrity of the product. Installers and contractors are vital players in the value chain since they can install industrial insulation projects.

Industrial Insulation Market Opportunity Analysis

Industrial insulation has a great chance because energy efficiency is becoming a more and more significant factor. With governments and businesses throughout the world investing in energy-saving projects, efficient insulation solutions are growing more and more attractive. There is a growing demand for environmentally friendly and sustainable insulating materials. This trend may benefit producers who design and sell environmentally friendly insulation products. By adding smart technology to insulation systems to enable real-time monitoring and control, innovation can be promoted. By providing information about potential issues, energy efficiency, and thermal performance, smart insulation can provide end users extra benefits. The development and industrialization of emerging markets have led to unmet possibilities for industrial insulation.

Industries are beginning to recognise the importance of cost-effectiveness and energy saving in their operations. In order to reduce operational expenses and energy consumption, industrial insulation is crucial for reducing heat absorption or loss. The need for energy efficiency is a significant element promoting the development of effective insulating systems. Many industrial operations require precise temperature control to guarantee high-quality products and operating efficiency.The use of industrial insulation helps keep equipment, pipes, and processing facilities at a steady temperature. This is crucial for industries where specific temperature ranges are required for chemical operations, such as petrochemicals. Stable working conditions are promoted by adequately insulated systems and equipment, which prevent temperature changes. This is crucial for industries like manufacturing and power generating.

Particularly for small and medium-sized enterprises (SMEs), industry may find it difficult to pay the high initial costs of high-quality insulating materials and installation. Although comprehensive insulation solutions could result in long-term energy savings, some businesses might be deterred from incurring the upfront cost. Insulation materials can degrade with time due to factors including moisture, physical damage, or exposure to harsh environments. Retrofitting insulation onto pre-existing industrial structures can provide logistical and financial challenges. If the complexity of retrofitting discourages industries from increasing insulation in older structures, the potential market as a whole may be limited. Providing insulating solutions that are universally applicable is challenging due to the huge differences in industrial processes across different industries.

Insights by Material

The mineral wool segment accounted for the largest market share over the forecast period 2023 to 2032. Mineral wool that is good at insulating against heat loss includes slag and rock wool. Because mineral wool effectively reduces heat transmission, it is beneficial to industries as an insulation material for machinery, pipelines, and industrial buildings. Mineral wool contributes to the safety of industrial facilities since it naturally resists fire. Because mineral wool insulation can withstand high temperatures and help prevent fires, it is popular in safety-conscious industries such as manufacturing and petrochemical. Mineral wool insulation is versatile and suitable for a wide range of industrial applications. It can be used in many forms to meet the requirements of various industrial installations, such as boards, blankets, and loose-fill insulation. Mineral wool is often thought of as an environmentally beneficial insulating material.

Insights by Form

Pipe segment is witnessing the fastest market growth over the forecast period 2023 to 2032. Energy efficiency in industrial processes is becoming more and more important. Pipe insulation reduces heat gain or loss in pipelines, hence encouraging conservation and energy efficiency. Industries search for solutions that are cost-effective and provide a strong return on investment. Pipe insulation reduces energy usage and yields long-term financial savings, making it a worthwhile investment for businesses. During industrial procedures, it is common to move fluids at different temperatures. Pipe insulation prevents heat loss in hot pipelines and minimises heat gain in cold pipelines, ensuring the stability of carried fluids. Industries require stable, dependable working conditions in order to generate high-quality items. Pipe insulation helps to maintain a constant temperature, ensuring that business operations continue as usual.

Insights by End User

The power segment accounted for the largest market share over the forecast period 2023 to 2032. Energy efficiency in industrial processes is becoming more and more important. Pipe insulation reduces heat gain or loss in pipelines, hence encouraging conservation and energy efficiency. Industries search for solutions that are cost-effective and provide a strong return on investment. Pipe insulation reduces energy usage and yields long-term financial savings, making it a worthwhile investment for businesses. During industrial procedures, it is common to move fluids at different temperatures. Pipe insulation prevents heat loss in hot pipelines and minimises heat gain in cold pipelines, ensuring the stability of carried fluids. Industries require stable, dependable working conditions in order to generate high-quality items. Pipe insulation helps to maintain a constant temperature, ensuring that business operations continue as usual.

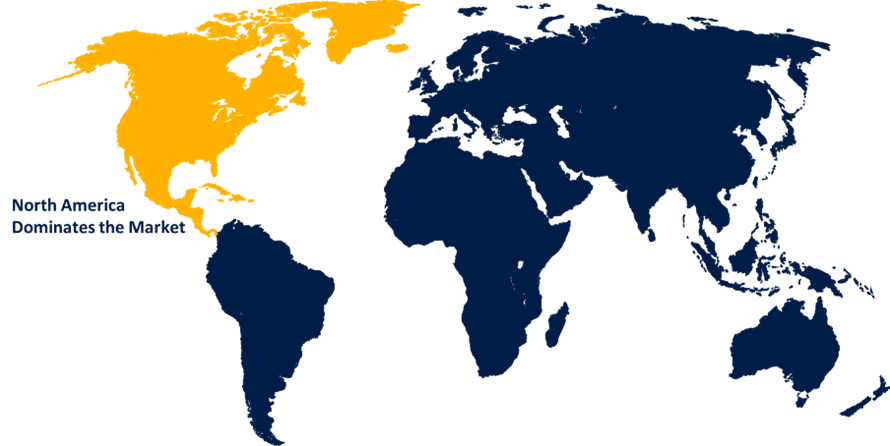

Insights by Region

Get more details on this report -

North America is anticipated to dominate the Industrial Insulation market from 2023 to 2032. Industrial insulation is an investment that businesses need to make in order to comply with regulations, reduce energy use, and boost overall energy efficiency. The construction of new manufacturing facilities, infrastructural projects, and industrial facilities has resulted in an increasing need for insulation in a range of applications. The oil and gas industry's requirement for insulation for processing plants, refineries, and pipelines is driving growth in the industrial insulation market. The use of insulation for thermal efficiency in manufacturing facilities affects the demand for insulation materials in the industrial sector. Industrial insulation is essential for the efficiency and performance of renewable energy installations, which will support the market's growth.

Asia Pacific is witnessing the fastest market growth between 2023 to 2032. The rise of many industries, such as manufacturing, energy, and construction, is driving an increasing demand for industrial insulation solutions. The growth of commercial and industrial establishments, as well as infrastructure developments, drives the need for insulation materials. An increasing number of residential, commercial, and industrial buildings need insulation for their building envelopes and HVAC systems. Manufacturing facilities seeking insulation to boost thermal efficiency are driving growth in the industrial insulation industry.

Major players in the market

- Armacell International S. A.

- Cabot Corporation

- Insulcon B. V.

- Johns Manville

- Kingspan Group PLC

- Knauf Insulation

- Owens Corning

- Promat (Etex Group)

- Rockwool Group and Saint Gobain

Market Segmentation

This study forecasts revenue at global, regional, and country levels from 2023 to 2032.

Industrial Insulation Market, Form Analysis

- Pipe

- Blanket

- Board

Industrial Insulation Market, Material Analysis

- Mineral Wool

- Calcium Silicate

- Plastic foams

Industrial Insulation Market, End Use Analysis

- Power

- Oil & Gas

- Cement

Industrial Insulation Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- South America

- Brazil

- Argentina

- Colombia

- Middle East & Africa

- UAE

- Saudi Arabia

- South Africa

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?