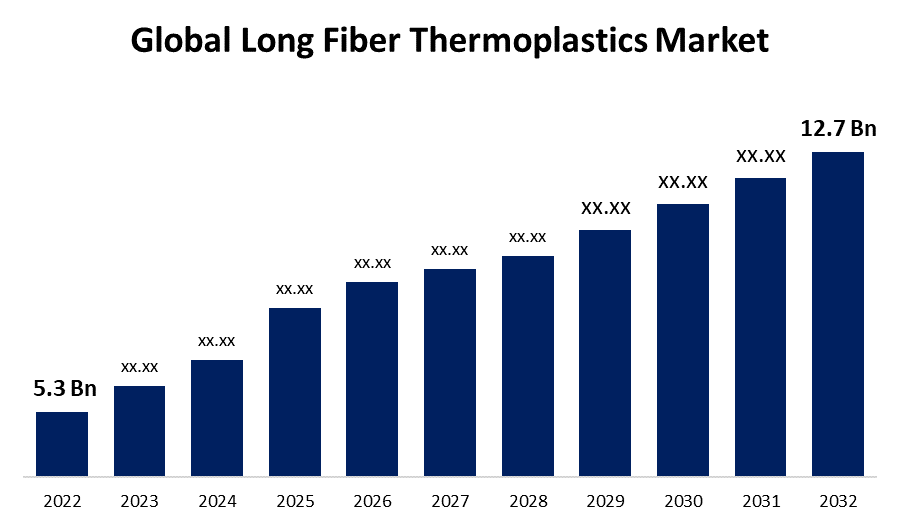

Global Long Fiber Thermoplastics Market Size To Worth USD 12.7 Billion by 2032 | CAGR of 11.8%

Category: Chemicals & MaterialsGlobal Long Fiber Thermoplastics Market Size To Worth USD 12.7 Billion by 2032

According to a research report published by Spherical Insights & Consulting, the Global Long Fiber Thermoplastics Market Size to grow from USD 5.3 billion in 2022 to USD 12.7 billion by 2032, at a Compound Annual Growth Rate (CAGR) of 11.8% during the forecast period.

Get more details on this report -

Browse key industry insights spread across 200 pages with 120 market data tables and figures & charts from the report on the "Global Long Fiber Thermoplastics Market Size, Share, and COVID-19 Impact By Resin Type (Polypropylene, Polyamide), By Fiber Type (Carbon, Glass), By End-User (Automotive, Building and Construction), By Manufacturing Process (Pultrusion, D-LFT), by Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2022 – 2032." Get Detailed Report Description Here: https://www.sphericalinsights.com/reports/long-fiber-thermoplastics-market

Long Fiber Thermoplastics (LFT), a type of composite material, are constructed from long reinforcing fibers and a thermoplastic matrix. The material created by this combination has better mechanical qualities than traditional short-fiber composites. LFT materials have the following qualities: strength, stiffness, impact resistance, and design flexibility. LFT materials are extensively used in the automotive industry for lightweight structural components such underbody shields, front-end modules, interior panels, and more. They help make cars lighter and more fuel-efficient.

COVID 19 Impact

Global supply networks were disrupted by the pandemic, which had an effect on the availability of raw materials and components. If manufacturers had a difficult time locating the fibers and thermoplastic resins they required, it might have had an impact on the development of LFT materials. Lockdowns and a decline in consumer demand may have led to production slowdowns in industries that heavily rely on composite materials, such as automotive and aerospace. The requirement for LFT in various sectors may have been impacted by this. The outbreak caused a shift in manufacturing priorities, with certain industries focusing on needs. This might have affected the production of non-essential items that use LFT.

One of the main drivers of the market's growth was the demand for lightweight materials across numerous industries, including the automotive and aerospace sectors. Due to their high strength-to-weight ratios, LFT composites are attractive for applications where weight reduction is crucial for improving overall performance, fuel efficiency, and emissions reduction. The automotive sector has made substantial use of LFT materials. Due to the need for lighter, more fuel-efficient vehicles as well as the need for strong, impact-resistant components, LFT composites are being utilized increasingly frequently for structural elements, interior panels, and underbody shields in automobiles. LFT materials provide design flexibility, allowing manufacturers to construct complex shapes and enhance component performance. Their versatility allows for a wide range of applications across numerous industries, which promotes market growth. These materials' uses are expanding outside of traditional industries (such automotive and aerospace) and into fields like building, consumer goods, and industrial machines as a result of the benefits they offer.

Despite having significant performance advantages, LFT materials might be more expensive than traditional short-fiber composites or alternative materials like metals. The higher production and material costs could make adoption more difficult, especially for price-sensitive industries. The perfect combination of reinforcing fibers and thermoplastic matrix must be chosen in order to produce the desired performance characteristics. This necessitates testing and knowledge in order to optimize the material for particular needs. The complexity of material choices may be challenging for producers. LFT materials are in competition with other lightweight materials including metals and continuous fiber-reinforced composites (CFRPs), each of which has advantages for specific applications. In order for LFT to successfully compete, it must present its unique value proposition.

Resin Type Insights

Polypropylene segment is dominating the market over the forecast period

On the basis of resin type, the global Long Fiber Thermoplastics Market is segmented into polypropylene, polyamide, polyether ether ketone, and others. Among these, the polypropylene segment is dominating the market with the largest market share over the forecast period. The automotive sector, a large consumer of LFT materials, is using LFT composites based on polypropylene more frequently for a range of components. PP-LFT materials provided a combination of lightweight design, exceptional impact resistance, and affordability for non-structural vehicle components. The use of PP-LFT materials was expanding outside the vehicle sector. The benefits of polypropylene-based LFT composites for lightweight, robust, and inexpensive components were being investigated by the consumer goods, industrial equipment, and construction industries. Polypropylene works well with injection molding, a common processing method used in the plastics sector. PP-LFT materials can be successfully molded into complicated shapes, making them applicable for a range of applications.

Fiber Type Insights

Glass fiber segment holds the highest market share over the forecast period

Based on the fiber type, the global long fiber thermoplastics market is segmented into carbon, glass, and others. Among these glass fiber segment holds the highest market share over the forecast period. Comparatively cheaper than other types of reinforcing materials like carbon fibers are glass fibers. This cost advantage makes glass fiber-reinforced LFT composites interesting for various applications, particularly those where cost considerations are crucial. Due to their widespread availability in a number of forms, such as rovings, chopped strands, and fabrics, glass fibers are easily incorporated into the LFT production process. The availability of glass fibers has an impact on production scalability. Glass fiber-reinforced LFT materials were becoming more popular outside of the automotive industry. Aircraft, consumer goods, and industrial equipment were among the sectors looking at the benefits of glass fiber-reinforced LFT composites for their mechanical performance and design flexibility.

End User Insights

The automotive segment dominates the market with the largest market share

On the basis of end user, the global long fiber thermoplastics market is segmented into automotive, building and construction, electrical and electronics, sporting goods, and others. Among these, the automotive segment is dominating the market over the forecast period. One of the key factors driving the usage of LFT materials is the focus on lightweighting in the automobile industry. LFT composites offer a desirable balance of high strength and low weight, particularly those produced with glass or carbon fibers. This is necessary to increase the overall performance of the vehicle, reduce emissions, and boost fuel efficiency. In the automotive industry, LFT materials are increasingly employed in underbody shields, non-structural exterior and interior portions, and structural and non-structural external and interior sections. LFT's benefits are now more extensively utilized throughout the vehicle.

Manufacturing Process Insights

Injection Molding segment holds the highest market share over the forecast period

Based on the manufacturing process, the global long fiber thermoplastics market is segmented into Pultrusion, D-LFT, injection molding, and others. Among these, the injection molding segment holds the highest market share over the forecast period. Due to its ability to produce intricate and sophisticated part designs, injection molding is preferred for making parts with unique shapes, multifunctional components, and complex geometries. Injection molding can make use of LFT materials to expand the range of component design options. Injection molding is a repeatable and highly effective process. It provides cost advantages over various other manufacturing processes in terms of labor savings, material use, and improved production efficiency. The total cost-effectiveness of the injection molding process can be increased by LFT materials, particularly those produced utilizing cost-effective thermoplastic matrices like polypropylene (PP). Injection-molded LFT materials are extensively used for a number of components in the automotive and aerospace industries, including interior panels, structural elements, underbody shields, and more.

Regional Insights

Asia Pacific is dominating the market over the forecast period

Get more details on this report -

Asia Pacific is dominating the market with the largest market share over the forecast period. Asia-Pacific has long been a manufacturing powerhouse for a variety of various industries and is a major producer of consumer electronics, industrial equipment, vehicle parts, and more. The need for lightweight materials has increased as a result of fuel economy and performance standards in these sectors, which has contributed to the growth of the LFT market. Demand for consumer goods, durable products, and automobiles has increased as the middle class has grown in many Asia-Pacific countries. In response, this has raised demand for strong, lightweight materials like LFT composites.

North America is witnessing the fastest market growth over the forecast period. North America, especially the United States, is a significant market for the automobile industry. The drive for lightweighting in the automotive sector to meet fuel efficiency standards and enhance vehicle performance has led to the development of LFT composites for numerous automotive components. The region has a thriving consumer goods industry, so manufacturers there routinely seek out durable, lightweight materials for everything from electronics to sporting goods. LFT composites offer a solution to meet these demands.

Market Segment

This study forecasts revenue at global, regional, and country levels from 2019 to 2032. Spherical Insights has segmented the global Long Fiber Thermoplastics Market based on the below-mentioned segments:

Long Fiber Thermoplastics Market, Resin Type Analysis

- Polypropylene

- Polyamide

- Polyether ether ketone

- Others

Long Fiber Thermoplastics Market, Fiber Type Analysis

- Carbon

- Glass

- Others

Long Fiber Thermoplastics Market, End User Analysis

- Automotive

- Building and construction

- Electrical and electronics

- Sporting goods

- Others

Long Fiber Thermoplastics Market, Manufacturing Process Analysis

- Pultrusion

- D-LFT, injection molding

- Others

Long Fiber Thermoplastics Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of Middle East & Africa

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?