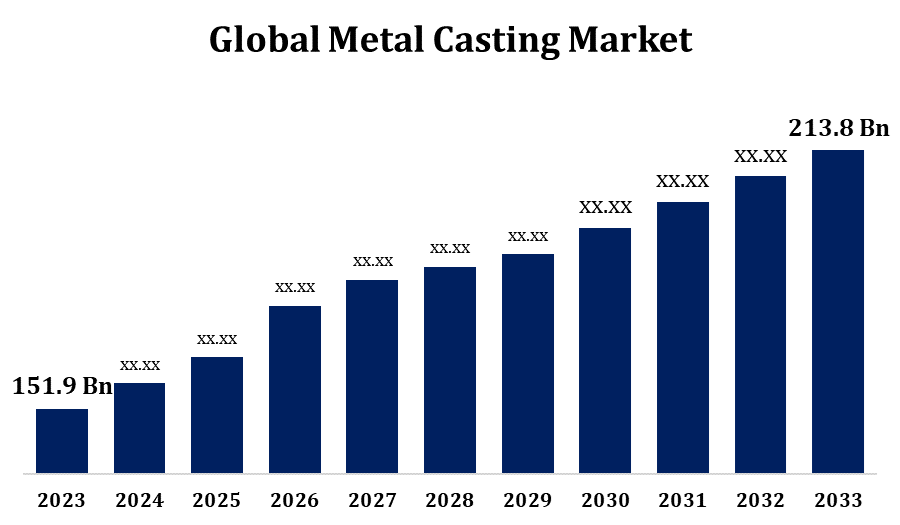

Global Metal Casting Market Size To Worth USD 213.8 Billion By 2033 | CAGR of 3.48%

Category: Automotive & TransportationGlobal Metal Casting Market Size To Worth USD 213.8 Billion By 2033

According to a research report published by Spherical Insights & Consulting, the Global Metal Casting Market Size to grow from USD 151.9 billion in 2023 to USD 213.8 billion by 2033, at a Compound Annual Growth Rate (CAGR) of 3.48% during the Forecast period.

Get more details on this report -

Browse key industry insights spread across 230 pages with 105 Market data tables and figures & charts from the report on the "Global Metal Casting Market Size, Share, and COVID-19 Impact Analysis, By Material Type (Cast Iron, Aluminum, Stainless Steel, Zinc, Magnesium), By Process (Sand Casting, Die Casting, Shell Mold Casting, Gravity Casting, Vacuum Casting), By End-Use (Automotive & Transportation, Building & Construction, Mining, Equipment & Machine, Consumer Goods), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2023 - 2033." Get Detailed Report Description Here: https://www.sphericalinsights.com/reports/metal-casting-market

The metal casting market is growing steadily, driven by increasing demand across industries such as automotive, aerospace, construction, and industrial machinery. This process, which involves pouring molten metal into molds to form complex shapes, remains popular due to its cost-effectiveness and suitability for mass production. The rising focus on lightweight and high-performance materials, especially in the automotive sector to enhance fuel efficiency and reduce emissions, is propelling market expansion. Additionally, innovations in casting technologies, including 3D printing and automation, are improving precision and lowering production costs. Despite challenges like environmental concerns and high initial investments, the market continues to expand. The Asia-Pacific region, led by China and India, dominates due to rapid industrialization and increasing infrastructure development.

Metal Casting Market Value Chain Analysis

The metal casting market value chain involves several key stages, beginning with raw material suppliers who provide metals like iron, aluminum, steel, and copper. Foundries and casting manufacturers then transform these materials using techniques such as sand casting, die casting, and investment casting to create specific components. Equipment and technology providers contribute by offering advanced machinery, automation solutions, and quality control systems to improve efficiency. Distributors and suppliers facilitate the connection between manufacturers and end-users across industries such as automotive, aerospace, construction, and machinery. End-users incorporate these cast components into their final products. Additionally, recycling and waste management play a vital role in sustainability by reprocessing scrap metal. Advancements in technology, streamlined supply chains, and regulatory compliance are crucial for enhancing productivity and maintaining market competitiveness.

Metal Casting Market Opportunity Analysis

The metal casting market offers significant growth opportunities fueled by technological advancements, rising industrialization, and sustainability initiatives. Increasing demand for lightweight and high-strength materials, particularly in the automotive and aerospace sectors, is driving the adoption of advanced casting techniques such as precision casting and 3D printing. Rapid infrastructure development and expanding manufacturing activities in emerging economies, especially in Asia-Pacific, further contribute to market expansion. The shift toward eco-friendly casting methods and the use of recycled metals support global sustainability efforts by reducing waste and energy consumption. Additionally, automation and digitalization in foundries are enhancing efficiency and quality, attracting investments in smart manufacturing. Companies that prioritize innovation, cost-effective production, and customization will strengthen their competitive position in this evolving market landscape.

The growth of the metal casting market is being driven by the expanding manufacturing sector, as industries increasingly depend on cast components for complex, high-performance applications. The automotive industry plays a key role, with rising demand for lightweight, fuel-efficient vehicles boosting the need for precision-cast parts. Likewise, the aerospace, construction, and industrial machinery sectors are adopting advanced casting techniques to enhance durability and efficiency. Emerging economies, particularly in Asia-Pacific, are investing heavily in large-scale manufacturing, further accelerating market demand. Additionally, advancements in automation, 3D printing, and improved alloy compositions are enhancing casting efficiency and quality. As manufacturers emphasize cost-effective and sustainable production, the metal casting market is set for substantial growth in the coming years.

Environmental issues such as high energy consumption, carbon emissions, and waste generation in foundries present regulatory and sustainability challenges. Stringent government regulations on emissions and waste disposal demand costly compliance measures, raising operational expenses. Additionally, fluctuating prices of raw materials like aluminum, steel, and copper create financial uncertainties for manufacturers. The industry is also grappling with a shortage of skilled labor, as casting processes require specialized expertise that is becoming scarce due to an aging workforce and limited training programs. Moreover, traditional casting techniques face growing competition from alternative manufacturing methods, including additive manufacturing (3D printing) and advanced machining, which are gaining traction for their efficiency and precision.

Insights by Material Type

The cast iron segment accounted for the largest market share over the forecast period 2023 to 2033. Cast iron is extensively utilized in automotive, construction, machinery, and pipe manufacturing due to its superior wear resistance, high compressive strength, and excellent machinability. Growing demand for heavy machinery and infrastructure development, especially in emerging economies, is fueling market growth. Furthermore, advancements in casting techniques, including enhanced mold designs and automation, are improving efficiency and product quality, further driving the expansion of the cast iron segment.

Insights by Process

The sand casting segment accounted for the largest market share over the forecast period 2023 to 2033. Growing demand from industries like automotive, aerospace, construction, and heavy machinery is driving the expansion of the sand casting segment. Innovations in sand mold technology, such as advanced binders and automation, are enhancing precision and efficiency. The increasing preference for customized and low-volume production further contributes to market growth. Additionally, the use of eco-friendly and reusable sand materials supports sustainability initiatives, making sand casting a preferred choice. The ongoing expansion of manufacturing activities, particularly in emerging economies, combined with continuous advancements in casting technologies, ensures sustained demand and long-term growth for the sand casting market.

Insights by End Use

The Automotive & Transportation segment accounted for the largest market share over the forecast period 2023 to 2033. Growth in the metal casting market is driven by rising vehicle production and the increasing demand for lightweight, high-strength components. Automakers are adopting cast aluminum and advanced alloys to enhance fuel efficiency and comply with strict emission regulations. The shift toward electric vehicles (EVs) is further fueling demand for precision-cast components in battery housings, motor casings, and structural parts. Additionally, advancements in casting technologies, including high-pressure die casting and automation, are improving production efficiency and quality. The expanding adoption of hybrid and electric transportation, along with the global rise in commercial and passenger vehicle fleets, is creating significant opportunities. Emerging markets in Asia-Pacific are accelerating growth, driven by increasing automotive manufacturing activities.

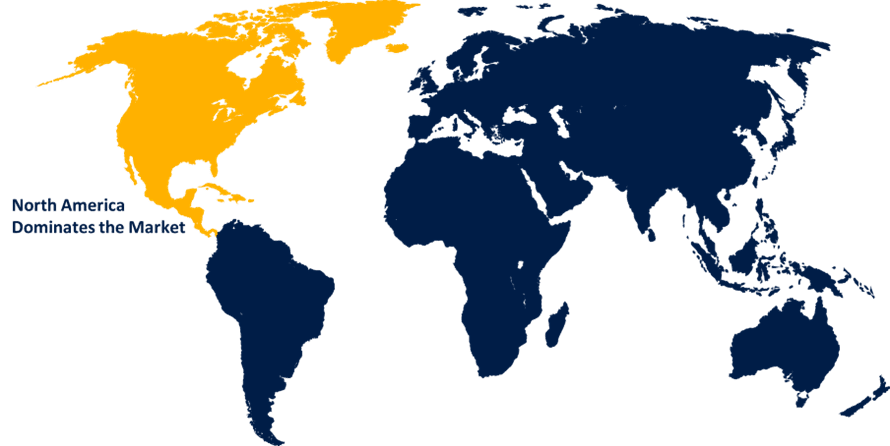

Insights by Region

Get more details on this report -

North America is anticipated to dominate the Metal Casting Market from 2023 to 2033. North America’s metal casting market benefits from advanced manufacturing technologies, strict quality standards, and a well-developed supply chain. The U.S. leads the industry, driven by its strong industrial base and the growing use of lightweight materials in automotive and aerospace applications. Additionally, the shift toward sustainable casting processes and increased use of recycled metals align with environmental regulations. Investments in automation, precision casting, and digital manufacturing are set to improve efficiency and competitiveness. Overall, the metal casting market in North America remains resilient, with steady growth prospects.

Asia Pacific is witnessing the fastest market growth between 2023 to 2033. India and Japan drive the market with their strong manufacturing base, affordable labor, and growing demand for cast components. The region benefits from abundant raw materials and government initiatives that promote domestic manufacturing. Increasing investments in construction, energy, and transportation further accelerate market growth. To stay competitive, manufacturers are integrating automation, precision casting, and eco-friendly processes. With rising demand for lightweight and high-performance materials, Asia-Pacific continues to be the dominant and fastest-growing region in the global metal casting market.

Recent Market Developments

- In July 2023, the American Foundry Society (AFS) introduced the AM for Metal Casting program to promote the adoption of additive manufacturing in metal casting. This initiative aims to help metal casters enhance their products and processes using advanced additive manufacturing technologies.

Major players in the market

- POSCO

- Dynacast

- Arconic

- Ryobi Limited

- Endurance Technologies Limited

- Alcast Technologies

- UNI Abex

- MES, Inc.

- CALMET

- Hitachi, Ltd.

Market Segmentation

This study forecasts revenue at global, regional, and country levels from 2023 to 2033.

Metal Casting Market, Material Type Analysis

- Cast Iron

- Aluminum

- Stainless Steel

- Zinc

- Magnesium

Metal Casting Market, Process Analysis

- Sand Casting

- Die Casting

- Shell Mold Casting

- Gravity Casting

- Vacuum Casting

Metal Casting Market, End Use Analysis

- Automotive & Transportation

- Building & Construction

- Mining

- Equipment & Machine

- Consumer Goods

Metal Casting Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?