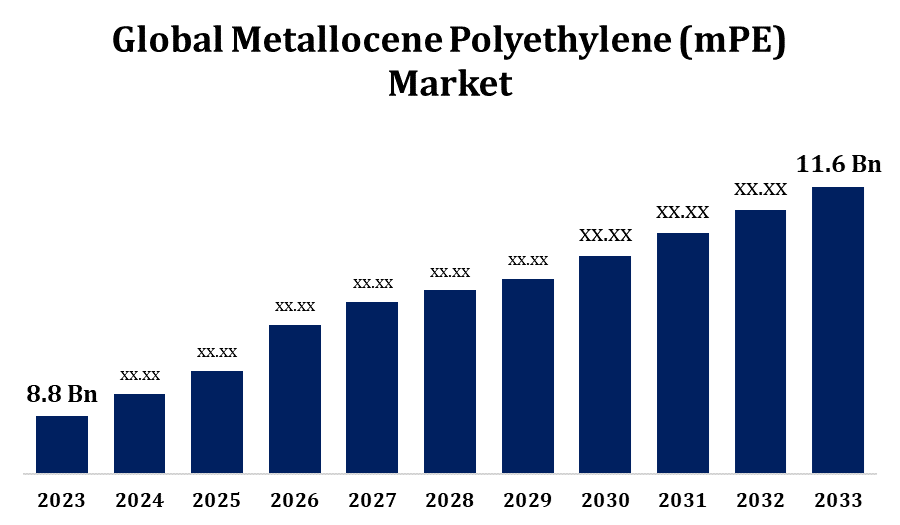

Global Metallocene Polyethylene (mPE) Market Size To Worth USD 11.6 billion By 2033 | CAGR of 2.80%

Category: Chemicals & MaterialsGlobal Metallocene Polyethylene (mPE) Market Size To Worth USD 11.6 billion By 2033

According to a research report published by Spherical Insights & Consulting, the Global Metallocene Polyethylene (mPE) Market Size to grow from USD 8.8 billion in 2023 to USD 11.6 billion by 2033, at a Compound Annual Growth Rate (CAGR) of 2.80% during the forecast period.

Get more details on this report -

Browse key industry insights spread across 230 pages with 115 Market data tables and figures & charts from the report on the "Global Metallocene Polyethylene (mPE) Market Size, Share, and COVID-19 Impact Analysis, By Product (mLLDPE, mHDPE, Others), By Application (Films, Sheets, Injection Moulding, Extrusion Coating, Others), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2023 – 2033." Get Detailed Report Description Here: https://www.sphericalinsights.com/reports/metallocene-polyethylene-mpe-market

The metallocene polyethylene (mPE) market is experiencing growth, fueled by its distinctive properties such as enhanced durability, clarity, and flexibility. mPE, a polyethylene variant produced with metallocene catalysts, allows for greater precision in polymer structure, leading to performance advantages over traditional polyethylene. This versatile material is popular across industries like packaging, healthcare, automotive, and consumer goods, thanks to its high impact resistance and durability against punctures and tears. Demand is rising particularly in food and pharmaceutical packaging, where sustainable, high-performance materials are essential. Furthermore, mPE’s recyclability aligns well with heightened environmental awareness and stricter regulations on single-use plastics. To capitalize on these trends, leading companies are investing in R&D to create new mPE products, further advancing market growth.

Metallocene Polyethylene (mPE) Market Value Chain Analysis

The metallocene polyethylene (mPE) market value chain comprises several essential stages, from raw material sourcing to end-user applications. It starts with the extraction and refinement of ethylene, the primary feedstock. During polymerization, metallocene catalysts are introduced to create high-quality mPE with enhanced properties. This production phase is typically led by major petrochemical companies investing in advanced manufacturing technologies. After production, mPE resin is sent to converters and processors, who shape it into films, sheets, and other forms for applications in packaging, medical products, and consumer goods. Distributors and suppliers play a crucial role, connecting manufacturers with end-users to ensure a steady supply and meet specific industry requirements. R&D efforts, regulatory standards, and increasing demand for sustainable materials further shape this value chain.

Metallocene Polyethylene (mPE) Market Opportunity Analysis

The metallocene polyethylene (mPE) market offers considerable growth opportunities, particularly in the packaging, automotive, and healthcare industries. Demand is rising for durable and flexible packaging materials that extend shelf life and ensure product integrity, driving mPE adoption in food and pharmaceutical packaging. With high puncture resistance, clarity, and recyclability, mPE is an appealing option aligned with the global trend toward sustainable, eco-friendly packaging. In the automotive sector, mPE films are gaining traction as lightweight materials that support fuel efficiency and reduce emissions. Advances in metallocene catalyst technology are also improving product quality and enabling specialized applications. Increased R&D investments are further expanding mPE’s properties and uses, propelling the market’s growth trajectory.

Demand for metallocene polyethylene (mPE) is growing in the packaging sector, a major factor driving its market expansion. Valued for its strength, flexibility, and clarity, mPE is increasingly preferred for high-performance packaging applications in food, pharmaceuticals, and personal care products. Its excellent impact and puncture resistance make it ideal for ensuring product safety, extending shelf life, and enhancing consumer appeal. Furthermore, mPE's recyclability aligns with the industry’s push for sustainable materials, appealing to eco-conscious brands and consumers alike. As the need for flexible, durable, and lightweight packaging solutions continues to grow globally, mPE is set to become a vital material. Advances in metallocene catalyst technology are also enhancing mPE’s quality, enabling custom packaging solutions and driving its adoption across various sectors.

A major challenge for the metallocene polyethylene (mPE) market is its high production cost relative to traditional polyethylene, driven by the expense of metallocene catalysts and complex manufacturing processes. This cost issue can hinder adoption, particularly in price-sensitive markets. Additionally, while mPE is valued for its recyclability, inadequate recycling infrastructure in many regions limits sustainable disposal and reuse. Fluctuating prices of raw materials, especially ethylene, add to cost volatility, impacting market stability. Environmental regulations and restrictions on plastic usage further push the industry to innovate and comply with sustainability standards. To address these challenges, leading companies are investing in R&D to improve production efficiency and explore sustainable alternatives, though scaling these solutions remains a challenge.

Insights by Type

The mLLDPE segment accounted for the largest market share over the forecast period 2023 to 2033. The growth of the mLLDPE segment is fueled by its unique properties, such as high tensile strength, flexibility, and impact resistance, making it ideal for applications like stretch films, packaging, and industrial films. The packaging industry, in particular, values mLLDPE for its outstanding clarity, puncture resistance, and lightweight nature, which enhance both product protection and shelf appeal. Additionally, demand for mLLDPE is rising as it supports sustainability goals by being recyclable and reducing material use in packaging. Advances in metallocene catalyst technology are further improving mLLDPE’s performance, opening doors for innovation and expansion. As industries increasingly seek high-performance, eco-friendly materials, the mLLDPE segment is well-positioned for significant global growth.

Insights by Application

The mPE films segment accounted for the largest market share over the forecast period 2023 to 2033. The growth of the mLLDPE segment is fueled by its unique properties, such as high tensile strength, flexibility, and impact resistance, making it ideal for applications like stretch films, packaging, and industrial films. The packaging industry, in particular, values mLLDPE for its outstanding clarity, puncture resistance, and lightweight nature, which enhance both product protection and shelf appeal. Additionally, demand for mLLDPE is rising as it supports sustainability goals by being recyclable and reducing material use in packaging. Advances in metallocene catalyst technology are further improving mLLDPE’s performance, opening doors for innovation and expansion. As industries increasingly seek high-performance, eco-friendly materials, the mLLDPE segment is well-positioned for significant global growth.

Insights by Region

Get more details on this report -

North America is anticipated to dominate the Metallocene Polyethylene (mPE) Market from 2023 to 2033. The growth of the mLLDPE segment is fueled by its unique properties, such as high tensile strength, flexibility, and impact resistance, making it ideal for applications like stretch films, packaging, and industrial films. The packaging industry, in particular, values mLLDPE for its outstanding clarity, puncture resistance, and lightweight nature, which enhance both product protection and shelf appeal. Additionally, demand for mLLDPE is rising as it supports sustainability goals by being recyclable and reducing material use in packaging. Advances in metallocene catalyst technology are further improving mLLDPE’s performance, opening doors for innovation and expansion. As industries increasingly seek high-performance, eco-friendly materials, the mLLDPE segment is well-positioned for significant global growth.

Asia Pacific is witnessing the fastest market growth between 2023 to 2033. The growth of the mLLDPE segment is fueled by its unique properties, such as high tensile strength, flexibility, and impact resistance, making it ideal for applications like stretch films, packaging, and industrial films. The packaging industry, in particular, values mLLDPE for its outstanding clarity, puncture resistance, and lightweight nature, which enhance both product protection and shelf appeal. Additionally, demand for mLLDPE is rising as it supports sustainability goals by being recyclable and reducing material use in packaging. Advances in metallocene catalyst technology are further improving mLLDPE’s performance, opening doors for innovation and expansion. As industries increasingly seek high-performance, eco-friendly materials, the mLLDPE segment is well-positioned for significant global growth.

Recent Market Developments

- On June 2019, Reliance Industries Limited (RIL) utilized Univation Technologies' UNIPOL PE Process to build a new polyethylene plant with increased production capacity.

Major players in the market

- Dow Chemical (US)

- Chevron Philips (US)

- ExxonMobil (US)

- LyondellBasell (Netherlands)

- Borealis (Germany)

- Total (US)

- Univation Technologies (US)

- Ineos (UK)

- SABIC (Saudi Arabia)

- Formosa Plastics Corporation (Taiwan)

- Prime Polymer Co., Ltd. (Japan)

- Westlake Chemical Corporation (US)

- China Petrochemical Corporation (China)

- Nova Chemicals Corporation (Canada)

- Sasol Limited (South Africa)

Market Segmentation

This study forecasts revenue at global, regional, and country levels from 2023 to 2033.

Metallocene Polyethylene (mPE) Market, Type Analysis

- mLLDPE

- mHDPE

- Others

Metallocene Polyethylene (mPE) Market, Application Analysis

- Films

- Sheets

- Injection Moulding

- Extrusion Coating

- Others

Metallocene Polyethylene (mPE) Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?