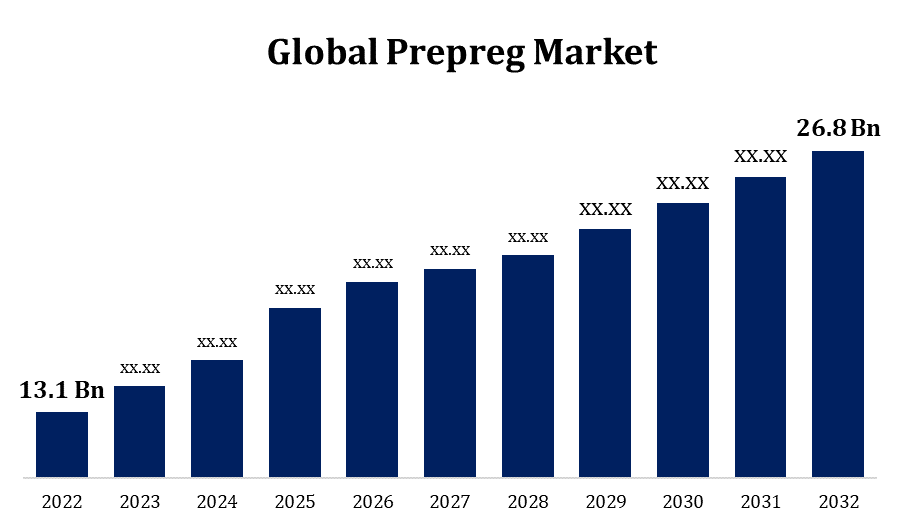

Global Prepreg Market Size To Worth USD 26.8 Billion by 2032 | CAGR of 11.9%

Category: Chemicals & MaterialsGlobal Prepreg Market Size To Worth USD 26.8 Billion by 2032

According to a research report published by Spherical Insights & Consulting, the Global Prepreg Market Size to Grow from USD 13.1 Billion in 2022 to USD 26.8 Billion by 2032, at a Compound Annual Growth Rate (CAGR) of 11.9% during the forecast period.

Get more details on this report -

Browse key industry insights spread across 200 pages with 110 Market data tables and figures & charts from the report on the "Global Prepreg Market Size By Manufacturing Process (Solvent Dip, Hot-Melt); By End-Use (Automotive, Aerospace, Electronics, Wind Energy, Others); By Resin (Thermoset Prepreg, Thermoplastic Prepreg), By Fiber (Carbon Fiber Prepreg, Glass Fiber Prepreg, Aeamid Fiber Prepreg, Other), By Region, And Segment Forecasts, By Geographic Scope And Forecast 2032." Get Detailed Report Description Here: https://www.sphericalinsights.com/reports/prepreg-market

Rising demand for lightweight and high-strength materials, particularly in aircraft, automotive, and wind energy, spurred this expansion. The trend towards more fuel-efficient and environmentally friendly solutions impacted the increased use of composites. Innovations in manufacturing processes and the development of advanced prepreg materials were also significant. Continuous R&D efforts were concentrated towards improving the performance, durability, and cost-effectiveness of prepreg materials, hence driving market growth.

Prepreg Market Value Chain Analysis

The process begins with the production of raw materials such as reinforcing fibres such as carbon, glass, or aramid and resin systems such as epoxy, phenolic, or thermoplastic resins. The next stage is the production of reinforcing fibres. Such methods include carbonisation for carbon fibres and spinning for glass fibres. Resin systems are tailored to the unique requirements of the application. This may require combining various chemicals to achieve desired properties such as flexibility, strength, and cure time. To make the actual prepreg, the resin system is infused into the reinforcing fibres. This is a crucial stage because it determines the composite material's ultimate qualities. Pregnancies are then terminated, frequently using heat and pressure. The cured prepreg material is then cut into the shapes and sizes that the customer has specified. It is packaged and ready for dispatch. Distributors are in charge of distributing prepreg materials to manufacturers. Manufacturers in a variety of industries, including aerospace, automotive, and sports, employ prepreg materials to build components.

Prepreg Market Opportunity Analysis

With the aerospace industry always looking for lightweight materials to improve fuel efficiency and performance, prepreg materials offer a lot of potential in aircraft manufacturing. With the aerospace industry always looking for lightweight materials to improve fuel efficiency and performance, prepreg materials offer a lot of potential in aircraft manufacturing. Prepreg materials have a promising market in the wind energy sector, specifically in the manufacture of wind turbine blades. The strength-to-weight ratio of composites is perfect for large, long-lasting blades. Prepreg materials, due to their strength and flexibility, present a potential in the sports equipment sector, including the fabrication of high-performance bicycles, tennis rackets, and other sporting products. Composites are increasingly being used in bridge, construction, and other infrastructure projects.

Automobile makers are researching ways to reduce vehicle weight in order to increase fuel efficiency and environmental sustainability. Prepreg materials are appealing for use in automotive components because they are lightweight yet strong, contributing to overall fuel efficiency. Prepregs have a high strength-to-weight ratio and excellent mechanical properties. As a result, they are suitable for use in high-performance vehicles where weight reduction is essential for improved acceleration, handling, and overall performance. As the automotive industry transitions to electric vehicles (EVs), there is a greater need for lightweight materials to offset the weight of batteries. Prepregs can aid in the development of lightweight, structurally robust EV components.

High-quality fibres and resins, for example, can be expensive raw ingredients in the prepreg manufacturing process. This cost is usually passed on to end users, lowering prepreg materials' competitiveness in price-sensitive sectors. A variety of sophisticated procedures, including fibre impregnation with resin and curing, are used to generate prepreg materials. This complexity may increase manufacturing costs since it demands specialised equipment and trained staff. The lack of standardised testing and processing techniques for prepreg materials might make it difficult to ensure consistent quality across manufacturers and applications. This can be a barrier to widespread adoption, especially in high-quality firms. Due to a lack of awareness, potential consumers may stick to traditional materials due to familiarity.

Insights by Resin

The thermoset resin segment accounted for the largest market share over the forecast period 2023 to 2032. Epoxy, phenolic, and other thermoset resins have several applications in a number of industries. They are widely used in aerospace, automotive, wind energy, and sports equipment manufacture due to their exceptional mechanical properties and high heat resistance. To make lightweight and high-strength components, the aerospace industry mainly relies on thermoset resin-based prepregs. Because of the goal for fuel-efficient aircraft and the need for robust yet lightweight materials, this sector is expanding. The use of thermoset resin-based prepregs is required for wind turbine blades. The growth of the wind energy sector, driven by greater investments in renewable energy, increases the need for these materials.

Insights by Fiber

The carbon fiber segment accounted for the largest market share over the forecast period 2023 to 2032. Carbon fiber-reinforced prepregs are widely used in the aerospace industry to manufacture lightweight, high-strength components such aircraft fuselages, wings, and interior structures. The growing demand for fuel-efficient aeroplanes has hastened the emergence of carbon fibre composites in this industry. In the automotive industry, lightweighting is becoming increasingly necessary in order to improve fuel efficiency and overall performance. Carbon fibre prepregs are utilised in the manufacturing of automotive components such as body panels, chassis parts, and interior elements. Carbon fibre prepregs are used to create high-performance equipment such as bicycles, tennis rackets, golf clubs, and sports gear in the sports and leisure business. The lightweight and strong qualities of carbon fibre contribute to improved athletic performance.

Insights by Manufacturing Process

The hot melt process segment accounted for the largest market share over the forecast period 2023 to 2032. The thermoplastic polymers used in the hot melt process melt when heated and solidify when cooled. This technology is notable for its efficiency and reduced processing time when compared to typical prepreg production methods. The hot melt technique is ideal for use in the automotive industry, notably for the fabrication of interior components. It allows for the quick production of interior panels, trim pieces, and acoustic components. The ability of the hot melt process to achieve fast cycle times is beneficial in areas where quick production turnaround is required. This is extremely important in the car sector and other businesses that demand high-volume production.

Insights by End Use

The aerospace segment accounted for the largest market share over the forecast period 2023 to 2032. Electric and hybrid-electric aircraft are becoming increasingly popular in the aerospace sector. Lightweight materials are usually prioritised in these aircraft designs for increased economy, offering up opportunities for the utilisation of prepreg materials. In response to rising demand for air travel, aerospace manufacturers are increasing production rates. As a result, there is a larger demand for novel materials, such as prepregs, to meet the production requirements of modern aircraft. The aerospace industry is expanding globally, with emerging markets playing a vital role. As new aircraft manufacturing facilities are created, the demand for advanced materials like as prepregs develops.

Insights from Region

Get more details on this report -

North America is anticipated to dominate the Prepreg Market from 2023 to 2032. The aircraft industry in North America has been a major consumer of prepreg materials. Because of their lightweight and high-strength properties, prepregs are ideal for aeroplane components, contributing to the region's aerospace dominance. The North American automobile industry has been using lightweight materials, like as prepregs, into vehicle design with a focus on fuel efficiency and emission reduction. This tendency is expected to continue as electric vehicles gain popularity. Wind energy has developed dramatically in response to rising demand for renewable energy. Prepreg materials are widely used in the production of wind turbine blades, and the number of wind farm installations in North America has increased. North American prepreg companies may engage in international trade and export activities.

Asia Pacific is witnessing the fastest market growth between 2023 to 2032. The Asia-Pacific area is a global manufacturing hub, and the demand for lightweight and high-performance materials in industries such as aerospace and automotive has pushed prepreg material adoption. Rapid expansion in countries such as China and India has increased demand for advanced materials. Prepregs are regarded for their versatility and strength, which allows them to be used in a wide range of manufacturing applications. Asia-Pacific aerospace and defence sectors are expanding. Prepreg materials are widely used in aircraft components, satellites, and defence applications due to their lightweight and durability. Sports and leisure products are getting more popular in Asia-Pacific. Prepreg materials are utilised in the manufacture of sports equipment such as bicycles, golf clubs, and racquets.

Recent Market Developments

- In April 2022, Hitachi Power Solution has announced the introduction of new services, including "Blade Total Service."

Major players in the market

- Evonik Industries AG (Germany)

- Teijin Limited (Japan)

- SGL Group (Germany)

- DSM (Netherlands)

- SABIC (Saudi Arabia)

- Solvay (Belgium)

- Hexcel Corporation (U.S.)

- Toray Industries Inc, (Japan)

- 3M (U.S.)

- BASF SE (Germany)

- Covestro AG (Germany)

- Dow (U.S.)

- Borealis AG (Austria)

- ZOLTEK (U.S.)

- Celanese Corporation (U.S.)

- Mitsubishi Chemical Corporation (Japan)

- PARK AEROSPACE CORP (U.S.)

- Gurit (Switzerland)

- Teijin Aramid B.V (Japan)

- Axiom Materials (U.S.)

Market Segmentation

This study forecasts revenue at global, regional, and country levels from 2023 to 2032.

Prepreg Market, Manufacturing Process Analysis

- Solvent Dip

- Hot-Melt

Prepreg Market, Fiber Analysis

- Carbon Fiber

- Glass Fiber

- Aeamid Fiber

- Other

Prepreg Market, Resin Analysis

- Thermoset

- Thermoplastic

Prepreg Market, End Use Analysis

- Automotive

- Aerospace

- Electronics

- Wind Energy

- Others

Prepreg Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- South America

- Brazil

- Argentina

- Colombia

- Middle East & Africa

- UAE

- Saudi Arabia

- South Africa

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?