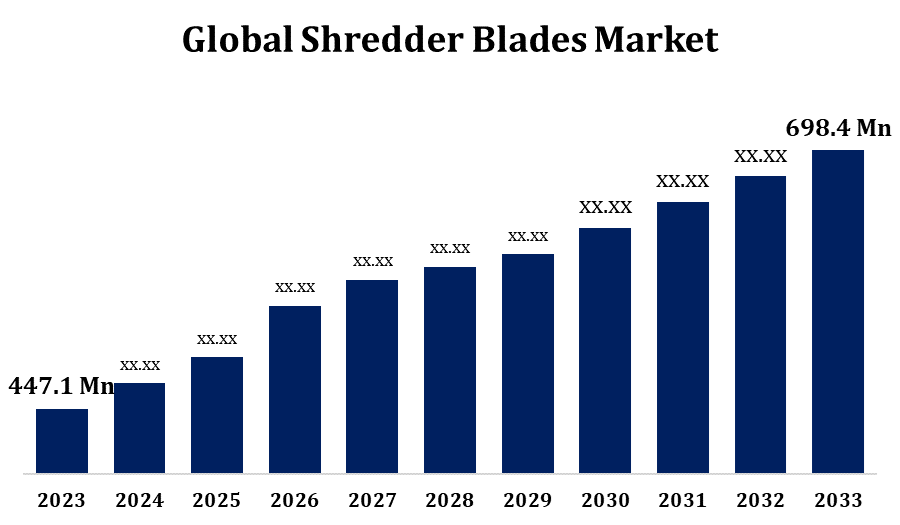

Global Shredder Blades Market Size To Worth USD 698.4 Million By 2033 | CAGR of 4.56%

Category: Machinery & EquipmentGlobal Shredder Blades Market Size To Worth USD 698.4 Million By 2033

According to a research report published by Spherical Insights & Consulting, the Global Shredder Blades Market Size to grow from USD 447.1 million in 2023 to USD 698.4 million by 2033, at a Compound Annual Growth Rate (CAGR) of 4.56% during the forecast period.

Get more details on this report -

Browse key industry insights spread across 235 pages with 102 Market data tables and figures & charts from the report on the "Global Shredder Blades Market Size, Share, and COVID-19 Impact Analysis, By Blade Material (Carburizing Steel, Tool Steel, Case Hardened, and Chromium Low Alloy Steel), By Blade Design (Hook and Square), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2023 - 2033." Get Detailed Report Description Here: https://www.sphericalinsights.com/reports/shredder-blades-market

The shredder blades market is experiencing growth driven by rising demand in industries such as recycling, waste management, and manufacturing. These blades are essential for efficient shredding machines and serve a variety of applications, including the shredding of plastics, metals, and wood. Increasing environmental awareness and government regulations regarding waste disposal are boosting the need for high-quality, durable blades that provide precise shredding and minimize waste volumes. Technological innovations, including the creation of wear-resistant and energy-efficient blades, are transforming the market landscape, appealing to eco-conscious businesses looking for sustainable options. The Asia-Pacific region leads in market growth, fueled by rapid industrialization and expanding recycling efforts, followed by North America and Europe. Key players are emphasizing product innovation and strategic partnerships to enhance their market presence and meet the growing demand for cost-effective, customized shredding solutions.

Shredder Blades Market Value Chain Analysis

The value chain of the shredder blades market comprises several stages, starting from raw material procurement to distribution to end users. Manufacturers utilize high-quality metals, such as alloy and stainless steel, to ensure the required durability and wear resistance. The processing phase involves forging, machining, and heat treatment to produce blades with precise cutting angles and hardness tailored for various applications. These blades are then distributed through direct sales, third-party suppliers, and online channels, serving industries like recycling, waste management, and metal processing. Each stage adds value through quality control and customization, enabling manufacturers to address specific industry demands for precision and efficiency. Additionally, aftermarket services like sharpening and maintenance enhance the overall product lifecycle, improving cost-effectiveness for end users and promoting market growth through extended usability.

Shredder Blades Market Opportunity Analysis

The value chain of the shredder blades market comprises several stages, starting from raw material procurement to distribution to end users. Manufacturers utilize high-quality metals, such as alloy and stainless steel, to ensure the required durability and wear resistance. The processing phase involves forging, machining, and heat treatment to produce blades with precise cutting angles and hardness tailored for various applications. These blades are then distributed through direct sales, third-party suppliers, and online channels, serving industries like recycling, waste management, and metal processing. Each stage adds value through quality control and customization, enabling manufacturers to address specific industry demands for precision and efficiency. Additionally, aftermarket services like sharpening and maintenance enhance the overall product lifecycle, improving cost-effectiveness for end users and promoting market growth through extended usability.

In the shredder blades market, growing awareness of waste recycling practices is fueling demand for efficient, high-quality blades tailored to various industries. As recycling initiatives expand—especially in sectors such as plastics, metals, and paper—companies are increasingly seeking durable and precise blades capable of handling large volumes while effectively reducing waste. Stricter regulations on waste management further motivate businesses to adopt advanced shredding technologies that promote blades designed to minimize energy consumption and prolong machine life. This trend is particularly evident in regions like Asia-Pacific and Europe, where recycling initiatives are rapidly progressing. Manufacturers focusing on sustainable blade materials and innovative designs are uncovering new growth opportunities, aligning with the industry's evolving needs and aiding businesses in achieving their waste reduction objectives.

In the shredder blades market, growing awareness of waste recycling practices is boosting the demand for efficient, high-quality blades tailored to various industries. As recycling initiatives expand—especially in sectors such as plastics, metals, and paper—companies are increasingly seeking durable and precise blades capable of handling high volumes and effectively minimizing waste. Stricter waste management regulations further drive businesses to adopt advanced shredding technologies that promote blades designed to reduce energy consumption and prolong machine life. This trend is particularly significant in regions like Asia-Pacific and Europe, where recycling efforts are advancing rapidly. Manufacturers that focus on sustainable blade materials and innovative designs are uncovering new growth opportunities, aligning with the industry's evolving needs and supporting businesses in achieving their waste reduction objectives.

Insights by Blade Material

The carburizing steel segment accounted for the largest market share over the forecast period 2023 to 2033. Carburizing steel, recognized for its superior surface hardness and impact resistance, is well-suited for blades utilized in heavy-duty shredding of materials like metal and plastic. This process fortifies the blade's exterior while preserving a tough core, enabling it to withstand continuous operation and the demanding conditions commonly found in recycling and waste management industries. The growing focus on cost-efficiency and blade durability in sectors such as metal processing has further increased the demand for carburized steel blades. Manufacturers are investing in carburizing technology to address industry-specific requirements, capitalizing on the high performance of this steel to lower maintenance costs and enhance shredding productivity across various industrial applications.

Insights by Blade Design

The hook segment accounted for the largest market share over the forecast period 2023 to 2033. Hook-shaped blades are particularly favored in industries that handle bulky or irregular materials, including metal scrap, plastic waste, and wood. Their design facilitates aggressive gripping and controlled tearing, making them ideal for applications that require precise and consistent shredding performance. The growing demand for recycling solutions in sectors committed to sustainable waste management has led to a higher adoption of hook blades, which provide enhanced durability and superior cutting efficiency. In response, manufacturers are improving the materials and sharpening techniques for hook blades, focusing on customized solutions that boost throughput and minimize operational downtime, aligning with the industry's needs for increased productivity and cost-effectiveness.

Insights by Region

Get more details on this report -

North America is anticipated to dominate the Shredder Blades Market from 2023 to 2033. Increasing regulatory pressure for environmental compliance has prompted companies to embrace advanced shredding technology, thereby improving waste processing efficiency. In industries such as metal recycling and plastic waste management, high-performance blades are essential, enabling precise and durable shredding to meet stringent quality standards. The United States and Canada are at the forefront of adopting eco-friendly and energy-efficient shredding solutions, driven by corporate sustainability initiatives and government incentives. Additionally, innovation in blade materials, including alloy steels and heat-treated metals, is being fueled by the demand for longer-lasting blades. Market participants are prioritizing research and development, along with strategic partnerships, to provide high-quality, customized shredding solutions that address a wide range of industrial needs.

Asia Pacific is witnessing the fastest market growth between 2023 to 2033. Countries in this region are witnessing increased demand for shredder blades, driven by the expansion of the recycling industry and more stringent environmental regulations. With extensive operations for recycling plastics, metals, and e-waste, the area necessitates efficient, durable blades capable of managing high-capacity shredding. Government initiatives that promote recycling and sustainable waste management further accelerate the adoption of advanced shredding technologies. Moreover, innovations in blade materials, such as wear-resistant alloys, along with customized blade designs, are addressing the diverse industrial requirements of the region. Major manufacturers are investing in local production facilities and forming partnerships to deliver cost-effective solutions, responding to the strong market demand across various sectors.

Recent Market Developments

- On Octobe 2022, AIShred has introduced a new version of its shredder machine that incorporates a single-shaft design.

Major players in the market

- KAMADUR industrial knives B.V (Netherlands)

- SATURN MACHINE KNIVES LTD (UK)

- Servo International (India)

- Anhui Yafei Machine Tool Co. Ltd (China)

- Fordura China (China)

- WANROOE MACHINERY CO., LTD. (China)

- Povelato srl (Italy)

- Miheu d.o.0. (Slovenia)

- Fernite Of Sheffield Ltd. (UK)

- BKS Knives (Belgium)

- Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. (China)

Market Segmentation

This study forecasts revenue at global, regional, and country levels from 2023 to 2033.

Shredder Blades Market, Blade Material Analysis

- Carburizing Steel

- Tool Steel

- Case Hardened

- Chromium Low Alloy Steel

Shredder Blades Market, Blade Design Analysis

- Hook

- Square

Shredder Blades Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?