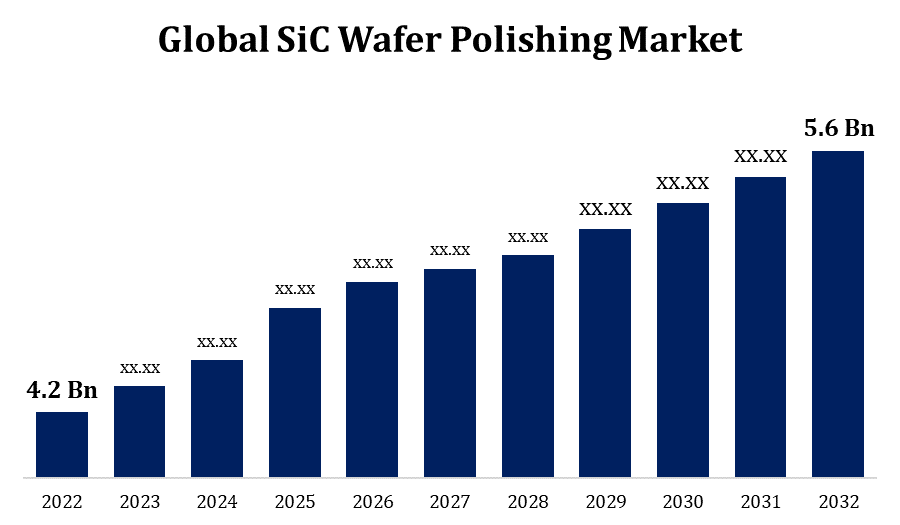

Global SiC Wafer Polishing Market Size To Worth USD 5.6 Billion by 2032 | CAGR Of 6.7%

Category: Semiconductors & ElectronicsGlobal SiC Wafer Polishing Market Size worth USD 5.6 Billion by 2032

According to a research report published by Spherical Insights & Consulting, the Global SiC Wafer Polishing Market Size to Grow from USD 4.2 Billion in 2022 to USD 5.6 Billion by 2032, at a Compound Annual Growth Rate (CAGR) of 6.7% during the forecast period.

Get more details on this report -

Browse key industry insights spread across 200 pages with 110 market data tables and figures & charts from the report on The "Global SiC Wafer Polishing Market Size By Product Type (Abrasive Powders, Polishing Pads, Diamond Slurries, Colloidal Silica Suspensions), By Application (Power Electronics, Light-emitting diodes (LEDs), Sensors and detectors, Rf and microwave devices, Others), By Region, And Segment Forecasts, By Geographic Scope And Forecast". Get Detailed Report Description Here: https://www.sphericalinsights.com/reports/global-sic-wafer-polishing-market

SiC (silicon carbide) wafers are becoming more popular, notably in power electronics and automotive applications. The polishing method is crucial for achieving the desired surface finish and quality. The increased demand for high-performance semiconductors in a variety of industries has increased the demand for SiC wafers. As technology advances, so does the desire for more efficient and long-lasting materials like silicon carbide. Polishing is critical for enhancing wafer surface flatness, smoothness, and overall quality. It's fascinating to examine how seemingly trivial actions contribute to electrical equipment's overall functionality.

SiC Wafer Polishing Market Value Chain Analysis

The basic raw material, silicon carbide (SiC), is utilised to begin the value chain. The extraction or synthesis of SiC powder is required. Sublimation or the modified Lely technique are then used to shape SiC powder into ingots or boules. These ingots are sliced into wafers using diamond wire saws or other cutting procedures. Wafers are lapped and ground to get the desired thickness and flatness. This is when the SiC wafer polishing comes into play. Chemical mechanical polishing (CMP) is a popular technique for removing surface flaws. After polishing, wafers are completely cleaned to remove any polishing residue. Inspection techniques ensure that quality standards are met.

SiC Wafer Polishing Market Opportunity Analysis

Determine the sectors and applications that are driving the demand for SiC wafers. Frequently included are power electronics, automobiles, telephones, and renewable energy. Examine the opportunities afforded by advancements in polishing technology. Innovations that boost productivity, reduce costs, or improve the quality of polished wafers can be potent motivators. Look at new and upcoming applications for SiC wafers. As technology progresses, SiC wafers may find applications outside of traditional semiconductor manufacturing. Examine the possibility for market expansion in various regions. As more industries adopt SiC technology, there may be untapped markets with increased demand. Analyse the supply chain to identify potential weaknesses and opportunities for improvement. The ability to maintain a resilient and efficient supply chain may be vital to market success.

In the polishing process, innovations in abrasive materials and tools contribute to finer surface finishes and better consistency. This can lead to higher yields and better wafer quality. The incorporation of automation and robotics into polishing operations improves efficiency and consistency. Automated solutions can enable real-time monitoring and correction, reducing human error and enhancing overall productivity. The polishing process may be examined in real time thanks to in-situ metrology and monitoring tools. This helps to maintain precise control of settings, optimise polishing results, and reduce flaws. Advances in slurry chemistry, such as the creation of customised abrasive particles and chemical compositions, aid in improving material removal rates and surface quality during polishing.

Silicon carbide is well-known for its hardness and brittleness. Polishing hard and brittle materials is tough because it requires precision to achieve the desired surface polish while avoiding defects. The abrasive nature of SiC wafers can induce tool wear and abrasion during polishing. Manufacturers are always challenged to keep polishing tools reliable and durable. While polishing, there is a risk of adding flaws such as scratches or surface damage. Furthermore, edge exclusion (the process of retaining the quality of the wafer's outside edges) might be challenging. Consumables like polishing slurries and abrasive powders can be costly. Finding cost-effective solutions while maintaining quality is a delicate balancing act that manufacturers must manage. It is vital to rely on a reliable supply network for raw materials.

Insights by Product Type

Diamond slurries segment accounted for the largest market share over the forecast period 2023 to 2032. The tremendous hardness of diamond particles is well recognised. The use of diamond slurries as polishing abrasives enables for more efficient material removal from SiC wafers, resulting in a smoother, more uniform surface. Diamond slurries aid in improving the surface quality of SiC wafers. Diamond abrasives remove surface defects and scratches, hence enhancing the overall quality of polished wafers. Diamond slurries are regularly modified by manufacturers to meet specific polishing requirements. Because of this flexibility, the polishing process can be adjusted based on factors such as particle size, concentration, and carrier fluid.

Insights by Application

Power Electronics segment accounted for the largest market share over the forecast period 2023 to 2032. SiC wafer utilisation in power electronics is being driven by increased demand for high-power electronic devices, notably in sectors such as electric vehicles, renewable energy, and industrial automation. The automobile industry's shift towards electric vehicles (EVs) and hybrid electric vehicles (HEVs) is a significant factor. SiC wafers are essential in the development of EV power electronics, resulting in the growth of the power electronics sector. SiC-based power electronics are widely used in renewable energy applications such as solar inverters and wind turbines. The increased emphasis on clean energy solutions is driving demand for SiC wafers in power electronics.

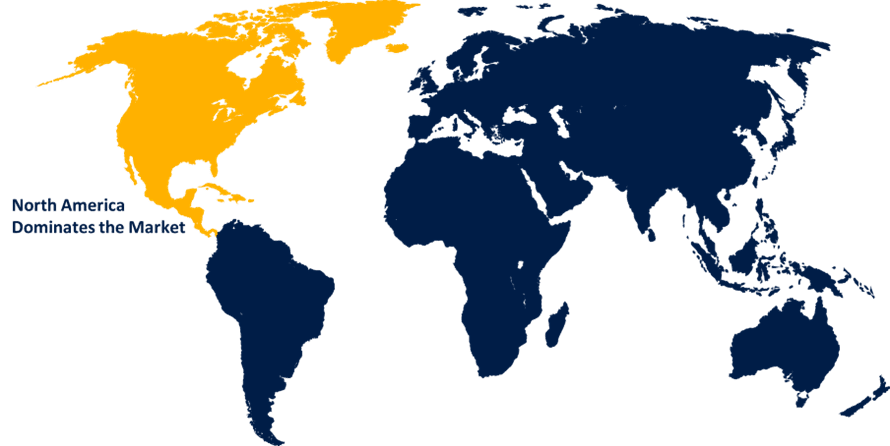

Insights by Region

Get more details on this report -

North America is anticipated to dominate the SiC Wafer Polishing Market from 2023 to 2032. The increased use of SiC wafers in power electronics applications such as inverters and power modules is driving demand in North America. This is especially essential in the field of renewable energy and the manufacture of electric cars (EVs). The increased emphasis on electric vehicles in North America has raised demand for SiC wafers, which are required for the development of efficient power electronics in electric vehicles. In addition to power electronics, SiC wafers are used in the aerospace, telecommunications, and defence industries. The diverse industrial landscape of North America contributes to the market's resilience. SiC is highly suited for application in harsh situations due to its ability to withstand high temperatures.

Asia Pacific is witnessing the fastest market growth between 2023 to 2032. Asia-Pacific, specifically Japan, South Korea, and Taiwan, is a global semiconductor manufacturing powerhouse. The region's significant presence in the electronics and semiconductor industries contributes to increased demand for SiC wafers. The Asia-Pacific region is the market leader in electric vehicles. The need for SiC wafers in the manufacturing of power electronics for EVs is increasing as the automotive industry transitions to electric mobility. The Asia-Pacific region is actively investing in renewable energy sources. SiC wafers are critical in power circuits for solar inverters and wind turbines, fueling the demand for polishing technologies. The growing markets of Southeast Asia are undergoing greater industrialization and infrastructure development.

Recent Market Developments

- In February 2023, Hindalco Industries Limited, India's largest nonferrous metals company, and Novelis Inc., the world's leading manufacturer of aluminium rolled products, have inked a definitive deal in which Hindalco will buy Novelis.

Major players in the market

- Kemnet International (UK)

- Entegris (US)

- Ijin Diamond (US)

- Fujimi Corporation (Japan)

- Saint-Gobain (US)

- JSR Corporation (Japan)

- Engis Corporation (US)

- Ferro Corporation (US)

- 3M (US)

- SKC (South Korea)

- DuPont Incorporated (US)

- Fujifilm Holding America Corporation (US)

Market Segmentation

This study forecasts revenue at global, regional, and country levels from 2023 to 2032.

SiC Wafer Polishing Market, Product Type Analysis

- Abrasive Powders

- Polishing Pads

- Diamond Slurries

- Colloidal Silica Suspensions

SiC Wafer Polishing Market, Application Analysis

- Power Electronics

- Light-emitting diodes (LEDs)

- Sensors and detectors

- Rf and microwave devices

- Others

SiC Wafer Polishing Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- South America

- Brazil

- Argentina

- Colombia

- Middle East & Africa

- UAE

- Saudi Arabia

- South Africa

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?