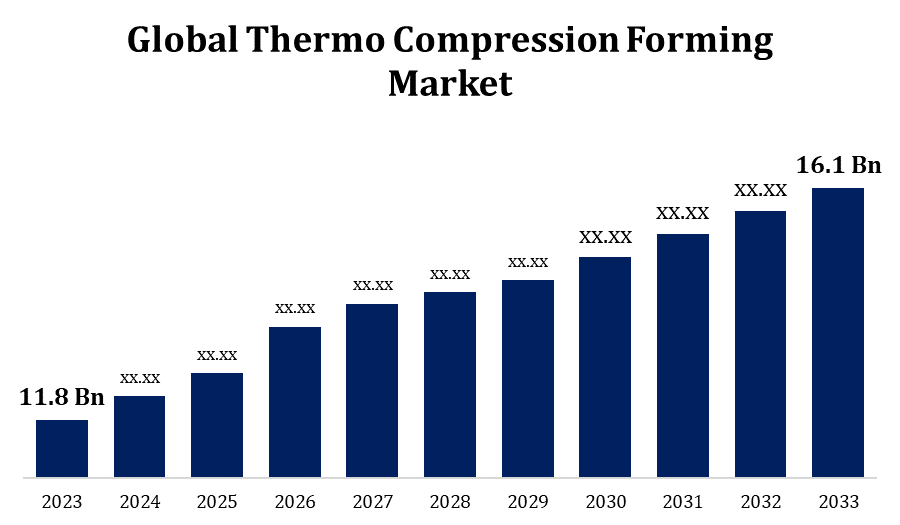

Global Thermo Compression Forming Market Size To Worth USD 16.1 Billion by 2033 | CAGR of 3.16%

Category: Advanced MaterialsGlobal Thermo Compression Forming Market Size To Worth USD 16.1 Billion by 2033

According to a research report published by Spherical Insights & Consulting, The Global Thermo Compression Forming Market Size to Grow from USD 11.8 Billion in 2023 to USD 16.1 Billion by 2033, at a Compound Annual Growth Rate (CAGR) of 3.16% during the forecast period.

Get more details on this report -

Browse key industry insights spread across 218 pages with 105 Market data tables and figures & charts from the report on the "Global Thermo Compression Forming Market Size, Share, and COVID-19 Impact Analysis, By Foam Type (Thermoplastic Foams, Needle-Punch Nonwovens, and Lightweight Glass Mat Thermoplastic), End-Use Industry (Automotive, Aerospace, Medical, Construction, Electrical & Electronics), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2023 - 2033." Get Detailed Report Description Here: https://www.sphericalinsights.com/reports/thermo-compression-forming-market

The thermo compression forming market is experiencing considerable growth, driven by its use across various industries such as automotive, aerospace, and consumer goods. This process entails heating thermoplastic materials until they become pliable and then compressing them into molds to produce complex shapes and components. The escalating demand for lightweight and high-strength materials is fueling the adoption of thermo compression forming, particularly in sectors prioritizing sustainability and energy efficiency. Advances in material science, along with improvements in manufacturing technologies, are enhancing the effectiveness of this process. Moreover, the surge in electric vehicles and renewable energy solutions is likely to stimulate market growth, as manufacturers seek efficient production techniques to satisfy the increasing consumer demand for eco-friendly products.

Thermo Compression Forming Market Value Chain Analysis

The value chain of the thermo compression forming market consists of several critical stages, beginning with raw material suppliers who provide thermoplastics and additives. These materials are processed by manufacturers utilizing thermo compression forming techniques to create finished components, requiring precise control of temperature and pressure to achieve optimal material performance. After production, the components are distributed to various end-use industries, including automotive, aerospace, and electronics. Each stage adds value through innovations in material properties and manufacturing efficiency, improving product performance and minimizing waste. Following manufacturing, components undergo rigorous quality control and testing before reaching consumers. The collaboration among suppliers, manufacturers, and end-users is essential for fostering technological advancements and promoting sustainability within the thermo compression forming market.

Thermo Compression Forming Market Opportunity Analysis

The thermo compression forming market offers significant opportunities fueled by the rising demand for lightweight materials across various sectors, especially in automotive and aerospace. With manufacturers focusing on energy efficiency and sustainability, the integration of advanced thermoplastic composites allows for substantial weight reduction without sacrificing strength, thereby improving overall performance. Moreover, the increasing trend towards electric vehicles necessitates innovative manufacturing processes for producing high-strength, durable components. The growing applications in consumer goods and electronics further enhance the market's potential. Additionally, emerging technologies like automation and advanced molding techniques are anticipated to optimize production and lower costs. Partnerships between material suppliers and manufacturers can drive the creation of new products, enabling companies to leverage changing market trends and fulfill consumer demands for eco-friendly solutions.

Increased investments in infrastructure development are playing a crucial role in the growth of the thermo compression forming market. With governments and private organizations directing funds toward enhancing transportation networks, energy facilities, and urban projects, the demand for high-performance materials and components capable of enduring challenging conditions is rising. Thermo compression forming, recognized for its capacity to produce lightweight and durable thermoplastic parts, is being increasingly adopted in construction equipment, transportation vehicles, and energy solutions. This trend not only drives innovation in material science but also fosters collaborations between manufacturers and infrastructure developers. Consequently, companies within the thermo compression forming sector are strategically positioned to capitalize on this growing demand, facilitating market expansion and improving product offerings to address the evolving requirements of infrastructure projects.

A key challenge in the thermo compression forming market is the substantial initial investment needed for advanced machinery and technology, which may discourage smaller manufacturers from entering the industry. Additionally, the variability in the material properties of thermoplastics can result in inconsistencies in product quality, requiring stringent quality control measures and incurring extra costs. The demand for skilled labor to operate complex equipment and maintain precision during manufacturing further complicates the production process. Furthermore, rising competition from alternative manufacturing techniques, such as injection molding and 3D printing, could restrict market share. Finally, fluctuations in raw material prices and supply chain disruptions can affect production costs and schedules, leading to uncertainty within the market landscape.

Insights by Foam Type

The thermoplastic foams segment accounted for the largest market share over the forecast period 2023 to 2033. These foams deliver exceptional thermal insulation, impact resistance, and cushioning, making them highly suitable for use in automotive, aerospace, and consumer goods applications. As manufacturers place greater emphasis on energy efficiency and sustainability, thermoplastic foams emerge as a viable solution for lightweighting components without sacrificing performance. The growing demand for energy-efficient vehicles and advanced packaging solutions further accelerates the expansion of this segment. Innovations in foam technology, such as improved structural integrity and recyclability, are also driving market growth. Moreover, the increasing focus on eco-friendly materials is in line with global sustainability trends, positioning thermoplastic foams as a significant contributor in the evolving landscape of thermo compression forming.

Insights by End Use Industry

The construction segment accounted for the largest market share over the forecast period 2023 to 2033. Thermo compression forming facilitates the efficient manufacturing of intricate structural components that improve energy efficiency and sustainability in construction projects. The increasing focus on green building practices and regulations encourages the use of advanced thermoplastics, which provide excellent insulation and help reduce carbon footprints. Moreover, the adoption of thermo compression formed components in prefabricated construction methods is becoming more prevalent, allowing for quicker project completion and enhanced quality control. As urbanization accelerates, the construction industry’s demand for innovative materials and techniques positions the thermo compression forming market for substantial growth, addressing the evolving architectural needs and promoting sustainable practices.

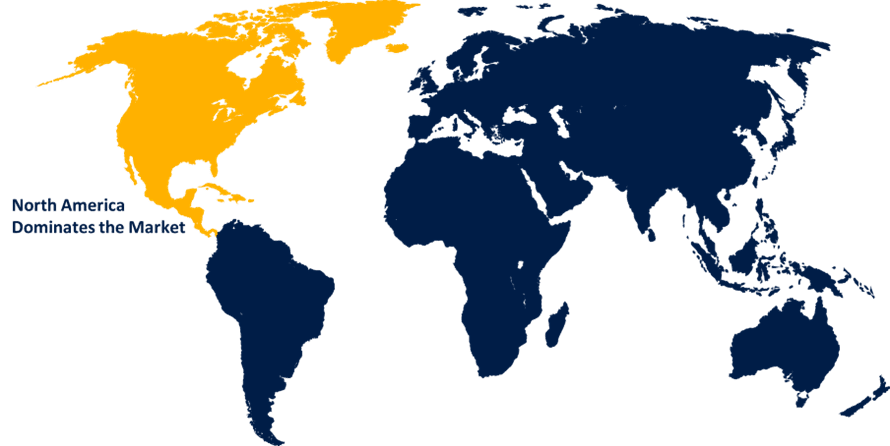

Insights by Region

Get more details on this report -

North America is anticipated to dominate the Thermo Compression Forming Market from 2023 to 2033. The region's focus on lightweight and high-strength materials is in line with the rising production of electric vehicles, which necessitate advanced components for improved efficiency and performance. Furthermore, supportive government initiatives aimed at promoting sustainable manufacturing practices are driving investments in thermo compression technology. The existence of well-established manufacturers and suppliers, along with continuous research and development efforts, encourages innovation and competitiveness within the market. However, challenges such as fluctuating raw material prices and competition from alternative manufacturing methods need to be addressed. Overall, North America's commitment to technological advancement and infrastructure development positions it as a significant player in the global thermo compression forming market.

Asia Pacific is witnessing the fastest market growth between 2023 to 2033. The increasing popularity of electric vehicles and renewable energy solutions is driving the adoption of thermo compression forming techniques, as manufacturers look for efficient production methods. Furthermore, government initiatives that promote sustainable practices and investments in advanced manufacturing technologies are improving market prospects. However, challenges like fluctuating raw material prices and the demand for skilled labor persist. Overall, the Asia Pacific market is poised to play a vital role in the global thermo compression forming landscape, presenting significant opportunities for growth and innovation.

Recent Market Developments

- On July 2024, FLEXTECH and Sun Path Products, Inc. have joined forces to choose and develop materials for the laminated and molded foam components of the Spyn System, which are critical for skydiving equipment.

Major players in the market

- BASF SE

- Core Molding Technologies

- Engineered Plastic Products Inc.

- FLEXTECH

- Formed Solutions

- Janco, Inc.

- Mitsubishi Chemical Group

- Present Advanced Composites Inc.

- Ray Products Company Inc.

- RCO Engineering

- Toray Advanced Composites

Market Segmentation

This study forecasts revenue at global, regional, and country levels from 2023 to 2033.

Thermo Compression Forming Market, Foam Type Analysis

- Thermoplastic Foams

- Needle-Punch Nonwovens

- Lightweight Glass Mat Thermoplastic

Thermo Compression Forming Market, End Use Industry Analysis

- Automotive

- Aerospace

- Medical

- Construction

- Electrical & Electronics

Thermo Compression Forming Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Follow Us: LinkedIn | Facebook | Twitter

Need help to buy this report?