Global 3D Printing Metals Market Size, Share, And COVID-19 Impact Analysis, By Metal Type (Titanium, Nickel, Stainless Steel, Aluminum & Others), By Form (Filament, Ink, Powder), By Vertical (Healthcare, Aerospace & Defense, Automotive, Heavy Industry, Manufacturing, Consumer Goods, Electronics & Electrical, & Others), And By Region (North America, Europe, Asia-Pacific, South America, Middle East, And Africa) Analysis And Forecast 2021 - 2030

Industry: Advanced MaterialsKEY MARKET INSIGHTS

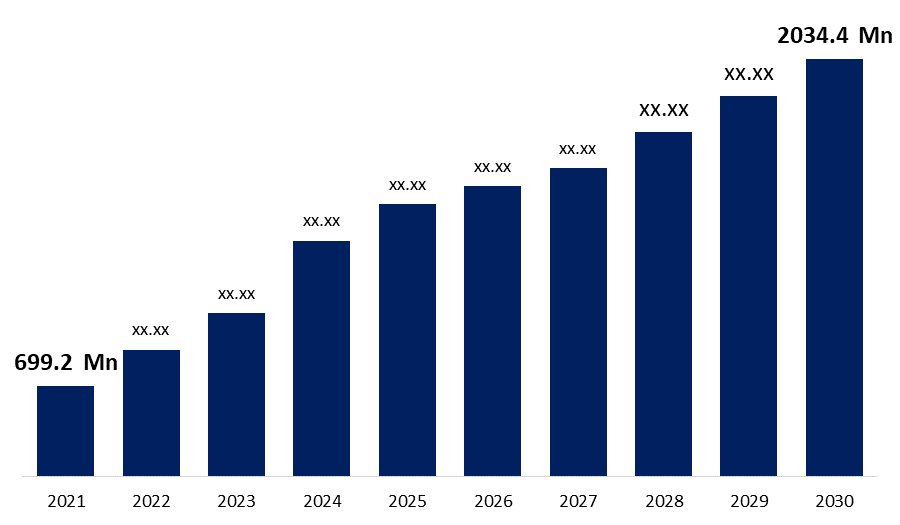

The Global 3D Printing Metals Market was valued at USD 699.2 Million in 2021. The market is projected to grow USD 2034.4 Million in 2030, at a CAGR of 24.6 %. 3D printing metals provide solid items with three-dimensionalities. These materials come in a variety of forms, including liquids, powders, and solids. Due to their high density and efficiency, 3D printing metals are gaining a lot of traction in the global market. These materials are used in aluminum, commercial vehicles, and various household items. 3D printing is suitable for bridging the short-term supply gap since it enables on-demand manufacture, customization, and quick adjustments to meet the needs of various hospitals, doctors, and users of personal protection equipment. It allows for mass customization at the same or equivalent unit costs. 3D printing type is gaining traction due to the increase significantly throughout the forecast period. Moreover, forward integration by major polymer aluminizes is one of the major drivers propelling the growth of the global 3D printing metals market.

Get more details on this report -

The industry is expected to rise due to the ease with which customized products can be developed, as well as favorable government investments making the growth of the global 3D printing metals market. Furthermore, increased demand from end-user industries like Automotive, medical, aerospace, and defense is expected to drive demand. The Automotive sector now has a lot of options thanks to recent breakthroughs in additive manufacturing. It has made it easier to create innovative, stronger, lighter, and safer components and parts with shorter lead times and lower costs. 3D printing was primarily used by OEMs for quick prototyping. As a result, the market expansion is likely to be fueled by increased product demand in the Automotive industry.

The outbreak of COVID-19 has had a significant influence on the worldwide 3D printing plastics market. The pandemic's impact on commercial and other industrial operations is projected to hinder the growth of the 3D printing plastics industry. The emergence of Covid-19 has pushed governments around the world to implement harsh measures such as lockdown, temporary shutdown, and social separation, resulting in a disruption in raw material production and, as a result, a rise in raw material costs. Raw material shipments have decreased, as has money generated. In addition, insufficient raw material supply would limit the manufacturing rate of 3D printing plastics, affecting the supply chain management of 3D printing plastics. Because of the outbreak, many market industries have been forced to suspend operations to follow government restrictions such as social distancing. As a result, the global 3D printing plastic business environment is unstable. This tendency is predicted to reverse in the second part of the year, as consumers grow more concerned about smart automation, energy efficiency, and resource efficiency.

Printing companies have used innovative print technologies to reduce costs, increase efficiency, and fulfill deadlines. 3D organ bioprinting and recyclable footwear are a few applications using advanced technologies for the growth of the global 3D Printing Metals market. 3D printing metals have improved the personalization of vehicle parts while also lowering manufacturing costs. Furthermore, it is also being used in the healthcare industry. The growing need for orthopedic and dental implants is propelling the 3D printing metals sector forward. Similarly, the demand for medical devices and equipment are propelling the expansion of the 3D printing metals market. For instance, EOS offers customized products in demand with 3D printing for various verticals such as automotive, healthcare, manufacturing, transportation, and many others.

The 3D Printing Metals are more expensive than traditional machines are anticipated to restrict the growth of the global 3D Printing Metals market during the forecast period. Industrial solutions have a higher cost and require more upkeep which has resulted in increasing prices. Nonetheless, the demand for maintaining and updating technologies follows the initial capital investments. As a result, the necessity for large initial investments and maintenance re-investments limits the growth of the global 3D printing metals market.

Global 3D Printing Metals Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2021 |

| Market Size in 2021: | USD 699.2 Million |

| Forecast Period: | 2021 - 2030 |

| Forecast Period CAGR 2021 - 2030 : | 24.6 % |

| 2030 Value Projection: | USD 2034.4 Million |

| Historical Data for: | 2017 - 2020 |

| No. of Pages: | 220 |

| Tables, Charts & Figures: | 121 |

| Segments covered: | By Metal Type, By Form, By Vertical, By Region |

| Companies covered:: | 3D Systems Corporation, Arcam AB, ExOne GmbH, Carpenter Technology Corp, Renishaw PLC, Proto Labs, Inc, Honeywell, Materialise NV, 3D Systems Corp, Voxeljet AG, GE, Sandvik AB, Hoganas AB, GKN PLC |

| Pitfalls & Challenges: | The outbreak of COVID-19 has had a significant influence on the worldwide 3D printing plastics market |

Get more details on this report -

SEGMENTATION

The global 3D Printing Metals market is segmented by Metal Type (Titanium, Nickel, Stainless Steel, Aluminum & Others), By Form (Filament, Ink, Powder), By Vertical (Healthcare, Aerospace & Defense, Automotive, Heavy Industry, Manufacturing, Consumer Goods, Electronics & Electrical, & Others) and region. Based on the Metal Type, the market is categorized into titanium, nickel, stainless steel, aluminum, & others. Based on Form, the market is categorized into filament, ink, and powder. Based on vertical, the market is categorized into healthcare, aerospace & defense, automotive, heavy industry, manufacturing, consumer goods, electronics & electrical, & others. Based on the region, the market is categorized into North America, Europe, Asia-Pacific, South America, Middle East and Africa.

Metal Type Insights

Based on the metal type segment, the global 3D Printing Metals market is categorized into titanium, nickel, stainless steel, aluminum & others. The titanium segment has dominated the market share of the global 3D printing metals market in 2020 owing to the rising usage of titanium-based products in different verticals due to its versatile properties such as lightweight, non-corrosion, and high-strength, toughness amongst others.

Form Insights

Based on the form segment, the global 3D Printing Metals market is categorized into filament, ink, and powder. The powder held the largest market share in 2020 of the global 3D printing metals market attributing to the demand is expected to be driven by strong properties combined with a surge in demand from many application industries such as food packaging, dinnerware, upholstery, and disposable clothes.

However, ink owing to the continuous research and development, as well as investments in smart ink development. These inks allow 3D printed structures to alter shape and color, hence improving their utility. Furthermore, researchers are concentrating their efforts on finding low-cost methods for manufacturing crucial elements in fields like biomechanics and energy.

Vertical Insights

Based on the vertical segment, the global 3D printing metals market is categorized into healthcare, aerospace & defense, automotive, heavy industry, manufacturing, consumer goods, electronics & electrical, & others. The healthcare segment is dominating the market share in 2020 owing to the product demand in medical applications being likely to be boosted by improved technology, favorable government backing, and quick product development. In addition, due to the outbreak of the COVID-19 pandemic, there is a growing demand for medical components such as face shields, mask clips, 3D printed masks and filter covers, and other medical components.

Get more details on this report -

REGIONAL INSIGHTS

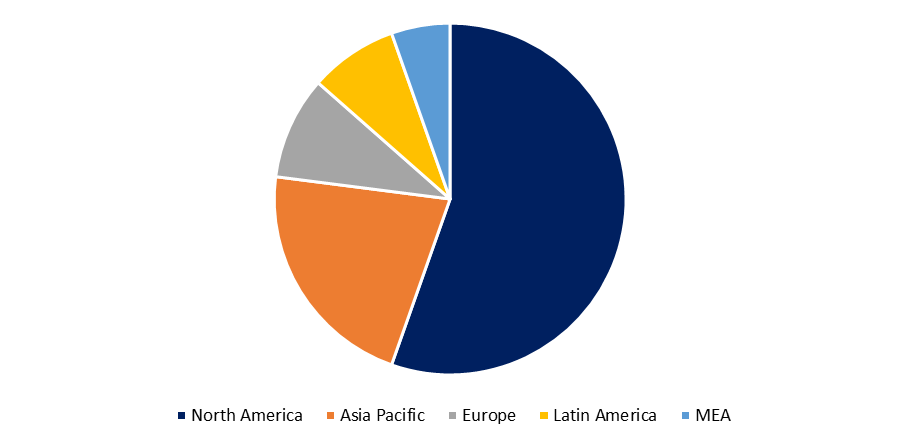

The global 3D Printing Metals market is categorized into North America, Europe, Asia-Pacific, Latin America, Middle East and Africa. North America region is dominating the market share of the global 3D Printing Metals market owing to the rising IoT applications and technological developments along with the presence of major players. The industry 4.0 drive to increase industrial productivity of the global 3d-printing metals market. The country's increasing medical end-use industry is driving demand for 3D printing plastics, thanks to the country's growing senior population. The mechanical and chemical properties of 3D-printed plastics have resulted in a surge in demand for 3D-printed polymers in medical devices. Biocompatibility, optical clarity, and cost-effective production methods are projected to drive product demand in the healthcare industry. However, the Asia Pacific region is anticipated to grow over the forecasted years owing to the increasing demand for 3D Printing Metals across the different Verticals. For instance, Cyfuse, a Japan-based startup, is currently focusing on a 3D printer that would be capable of producing 3D cellular products for practical use.

KEY INDUSTRY PLAYERS

- 3D Systems Corporation

- Arcam AB

- ExOne GmbH

- Carpenter Technology Corp.

- Renishaw PLC

- Proto Labs, Inc.

- Honeywell

- Materialise NV

- 3D Systems Corp.

- Voxeljet AG

- GE

- Sandvik AB

- Hoganas AB

- GKN PLC

- Others

KEY INDUSTRY DEVELOPMENTS:

October 2020- Honeywell has announced performing one evaluation of additive manufacturing (AM) material, alloy ABD 900AM for the usage in aerospace.

SEGMENTATION

By Metal Type

- Titanium

- Nickel

- Stainless Steel

- Aluminum

- Others

By Form

- Filament

- Ink

- Powder

By Vertical

- Healthcare

- Aerospace & Defense

- Automotive

- Heavy Industry

- Manufacturing

- Consumer Goods

- Electronics & Electrical

- Others

By Region

- North America- U.S., Mexico, Canada

- Europe- UK, France, Germany, Italy

- Asia-Pacific- China, Japan, India

- Latin America- Brazil, Argentina, Colombia

- The Middle East and Africa- United Arab Emirates, Saudi Arabia

Need help to buy this report?