Global Aerospace Adhesives Market Size, Share, and COVID-19 Impact Analysis, By Product (Water-based, Solvent-based), By Application (Commercial Aviation, Military Aviation, General Aviation), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2023 - 2033

Industry: Aerospace & DefenseGlobal Aerospace Adhesives Market Insights Forecasts to 2033

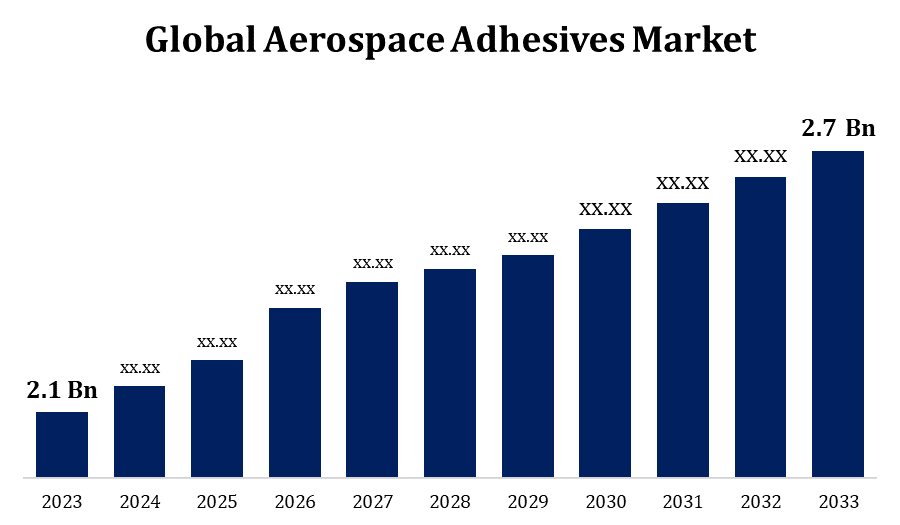

- The Aerospace Adhesives Market Size was valued at USD 2.1 Billion in 2023.

- The Market Size is Growing at a CAGR of 2.54% from 2023 to 2033.

- The Worldwide Aerospace Adhesives Market Size is expected to reach USD 2.7 Billion by 2033.

- Asia Pacific is expected to Grow the fastest during the forecast period.

Get more details on this report -

The Global Aerospace Adhesives Market Size is expected to reach USD 2.7 Billion by 2033, at a CAGR of 2.54% during the forecast period 2023 to 2033.

The aerospace adhesives market is experiencing significant growth due to increased demand for lightweight and fuel-efficient aircraft. Adhesives play a crucial role in bonding various components, providing durability and resistance to extreme temperatures, pressure, and vibrations. The market is driven by the rising adoption of advanced composite materials in both commercial and military aircraft to enhance performance and reduce overall weight. Additionally, the increasing focus on replacing traditional fasteners with high-performance adhesives is contributing to the expansion of this market. Major sectors like maintenance, repair, and overhaul (MRO) services also bolster the demand for aerospace adhesives. Geographically, North America leads due to its well-established aerospace industry, while Asia-Pacific is emerging as a lucrative market driven by the rising number of aircraft manufacturers and increasing defense spending.

Aerospace Adhesives Market Value Chain Analysis

The aerospace adhesives market value chain comprises raw material suppliers, manufacturers, distributors, and end-users, each playing a pivotal role in delivering quality products. Raw material suppliers provide essential inputs like resins, polymers, and curing agents to adhesive manufacturers, who formulate products tailored for specific aerospace applications. Manufacturers focus on research and development to enhance adhesive properties, such as bonding strength, durability, and resistance to extreme environmental conditions. Distributors then bridge the gap between manufacturers and end-users by ensuring timely availability and compliance with aerospace standards. End-users include aircraft OEMs (original equipment manufacturers), MRO (maintenance, repair, and overhaul) service providers, and defense contractors who rely on adhesives for assembly, repair, and upgrades. This integrated value chain ensures that aerospace adhesives meet stringent performance, safety, and regulatory requirements.

Aerospace Adhesives Market Opportunity Analysis

The aerospace adhesives market presents significant growth opportunities driven by technological advancements and increasing demand for lightweight, fuel-efficient aircraft. With the aviation industry shifting towards composite materials and the need to reduce the overall weight of aircraft, high-performance adhesives are becoming essential in replacing traditional mechanical fasteners. This trend opens avenues for innovation in adhesive formulations, such as the development of flame-resistant and high-temperature adhesives. The growing focus on urban air mobility (UAM) and electric aircraft also presents new market prospects, as these segments require specialized bonding solutions. Additionally, the expansion of the Maintenance, Repair, and Overhaul (MRO) sector, particularly in Asia-Pacific and the Middle East, is expected to create substantial demand for adhesives, presenting lucrative opportunities for manufacturers and suppliers in this sector.

Global Aerospace Adhesives Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2023 |

| Market Size in 2023: | USD 2.1 Billion |

| Forecast Period: | 2023 - 2033 |

| Forecast Period CAGR 2023 - 2033 : | 2.54% |

| 2033 Value Projection: | USD 2.7 Billion |

| Historical Data for: | 2019 - 2022 |

| No. of Pages: | 218 |

| Tables, Charts & Figures: | 110 |

| Segments covered: | By Product, By Application, By Region. |

| Companies covered:: | PPG Industries, 3M, Henkel, Solvay, Flamemaster, Chemetall, Royal Adhesives & Sealants, Dow Corning, Permatex, Master Bond, and Others |

| Growth Drivers: | Growth In the Aerospace Industry |

| Pitfalls & Challenges: | COVID-19 Empact, Challenge, Future, Growth, & Analysis |

Get more details on this report -

Market Dynamics

Aerospace Adhesives Market Dynamics

Growth In the Aerospace Industry

The aerospace adhesives market is experiencing robust growth, primarily driven by the expansion of the global aerospace industry. Increased production rates of commercial aircraft, spurred by rising air travel demand and fleet modernization, have led to a surge in adhesive consumption. The industry’s push for fuel-efficient and lightweight designs has resulted in greater adoption of advanced materials like composites, which require specialized adhesives for assembly and structural bonding. Moreover, the defense sector’s investments in next-generation military aircraft and unmanned aerial vehicles (UAVs) further bolster market growth. The proliferation of new aerospace programs and regional expansion in emerging markets, particularly in Asia-Pacific, are driving additional opportunities. This growth is complemented by advancements in adhesive technology, which are enabling manufacturers to meet stringent performance and safety standards across diverse aerospace applications.

Restraints & Challenges

One of the primary concerns is the high cost associated with the development and production of advanced adhesives that meet stringent aerospace standards, making it difficult for manufacturers to maintain competitive pricing. Additionally, these adhesives must comply with strict safety, environmental, and performance regulations, requiring rigorous testing and certification processes that increase time-to-market. Fluctuations in raw material prices, especially for specialty resins and polymers, add further cost pressures. The market also faces limitations in terms of adhesive compatibility with newer composite materials, which can impact long-term durability and performance. Moreover, the relatively slow adoption of new technologies in the aerospace sector due to safety concerns can delay innovation and hinder the widespread use of novel adhesive solutions.

Regional Forecasts

North America Market Statistics

Get more details on this report -

North America is anticipated to dominate the Aerospace Adhesives Market from 2023 to 2033. The region's strong demand is fueled by high production rates of commercial and military aircraft, as well as extensive Maintenance, Repair, and Overhaul (MRO) activities. The U.S. government's focus on modernizing its defense fleet and increasing investments in space exploration further bolsters adhesive consumption. Additionally, stringent safety and quality standards in North America create demand for specialized adhesives that ensure structural integrity and high performance under extreme conditions. The region is also a hub for research and development in adhesive technologies, fostering innovation and enabling manufacturers to develop high-performance products tailored to evolving aerospace applications.

Asia Pacific Market Statistics

Asia Pacific is witnessing the fastest market growth between 2023 to 2033. Countries like China, India, and Japan are expanding their aerospace capabilities, driven by rising passenger traffic, fleet expansion, and the emergence of new aircraft manufacturing facilities. The region’s focus on developing indigenous aerospace programs, along with collaborations with global players, is boosting demand for high-performance adhesives. Furthermore, significant investments in defense and space exploration projects create additional growth avenues. The growing Maintenance, Repair, and Overhaul (MRO) sector in the region, supported by the need to maintain a burgeoning aircraft fleet, further enhances market prospects. Favorable government policies and initiatives to bolster local manufacturing and reduce dependence on imports make Asia-Pacific a lucrative market for aerospace adhesive manufacturers.

Segmentation Analysis

Insights by Product

The water-based products segment accounted for the largest market share over the forecast period 2023 to 2033. Water-based adhesives, which have lower volatile organic compound (VOC) emissions compared to solvent-based alternatives, are gaining traction as the industry prioritizes eco-friendly and safer materials. These adhesives offer excellent bonding properties while minimizing health and safety risks for workers during application. Advancements in water-based adhesive formulations have improved their performance, making them suitable for various aerospace applications, including interior cabin components and non-structural assemblies. As aerospace manufacturers aim to reduce their environmental footprint and meet stringent compliance standards, the demand for water-based adhesives is expected to rise, presenting growth opportunities for companies focusing on green and sustainable product lines.

Insights by Application

The commercial aviation segment accounted for the largest market share over the forecast period 2023 to 2033. Leading aircraft manufacturers such as Boeing and Airbus are ramping up production to meet the growing demand for new, fuel-efficient models, which, in turn, is boosting the need for high-performance adhesives. These adhesives play a vital role in reducing aircraft weight by enabling the use of advanced composite materials, thereby enhancing fuel efficiency and reducing emissions. Moreover, the need for lightweight bonding solutions for interior components, such as seating and paneling, is further fueling demand. As airlines focus on fleet modernization and upgrades to improve operational efficiency and passenger comfort, the commercial aviation segment will continue to be a major growth driver for the aerospace adhesives market.

Recent Market Developments

- In July 2022, Hexcel Corporation has partnered with Spirit AeroSystems Europe at its Aerospace Innovation Centre (AIC) to jointly develop more sustainable manufacturing technologies aimed at advancing future aircraft production.

Competitive Landscape

Major players in the market

- PPG Industries

- 3M

- Henkel

- Solvay

- Flamemaster

- Chemetall

- Royal Adhesives & Sealants

- Dow Corning

- Permatex

- Master Bond

- Others

Market Segmentation

This study forecasts revenue at global, regional, and country levels from 2023 to 2033.

Aerospace Adhesives Market, Product Analysis

- Water-based

- Solvent-based

Aerospace Adhesives Market, Application Analysis

- Commercial Aviation

- Military Aviation

- General Aviation

Aerospace Adhesives Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

Frequently Asked Questions (FAQ)

-

1. What is the market size of the Aerospace Adhesives Market?The global Aerospace Adhesives Market is expected to grow from USD 2.1 billion in 2023 to USD 2.7 billion by 2033, at a CAGR of 2.54% during the forecast period 2023-2033.

-

2. Who are the key market players of the Aerospace Adhesives Market?Some of the key market players of the market are PPG Industries, 3M, Henkel, Solvay, Flamemaster, Chemetall, Royal Adhesives & Sealants, Dow Corning, Permatex, and Master Bond.

-

3. Which segment holds the largest market share?The commercial aviation segment holds the largest market share and is going to continue its dominance.

-

4. Which region dominates the Aerospace Adhesives Market?North America dominates the Aerospace Adhesives Market and has the highest market share.

Need help to buy this report?