Global Aerospace and Defense Additive Manufacturing Market Size, Share, and COVID-19 Impact Analysis, By Platform (Aviation (Aircraft and UAV), Defense (Combat Vehicles, Military PPE, Weapons, Submarine Hulls, and Others), Space (Engines, Satellites, Spacecraft, and Rockets)), By Vertical (Printer, Material, and Others), By Application (Engine Components, Space Components, Structural Components, Defense Equipment, and Others), By Technology (FDM, DMLS, SLA, CLIP, SLS, and Others), By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2023 - 2033

Industry: Aerospace & DefenseGlobal Aerospace and Defense Additive Manufacturing Market Insights Forecasts to 2033

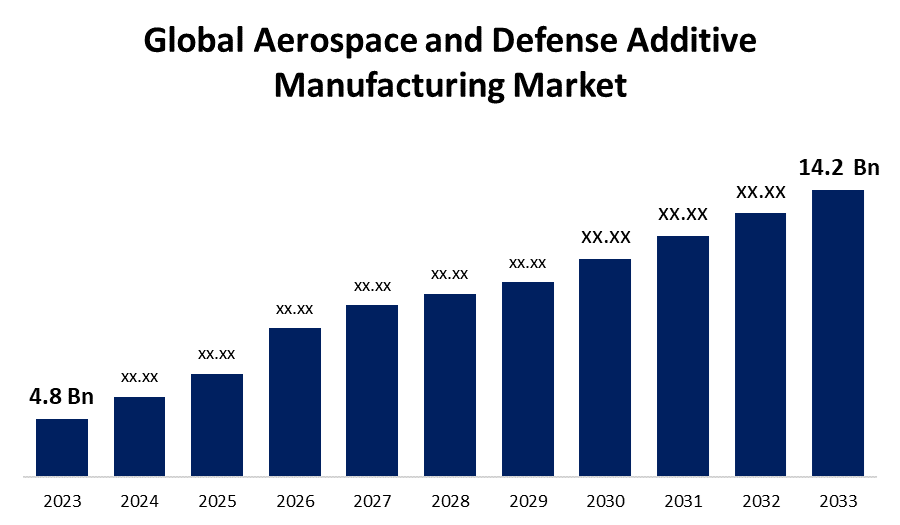

- The Aerospace and Defense Additive Manufacturing Market Size was valued at USD 4.8 Billion in 2023.

- The Market Size is Growing at a CAGR of 11.46% from 2023 to 2033

- The Worldwide Aerospace and Defense Additive Manufacturing Market Size is Expected to reach USD 14.2 Billion by 2033

- Asia Pacific is Expected to Grow the fastest during the forecast period

Get more details on this report -

The Global Aerospace and Defense Additive Manufacturing Market Size is Expected to reach USD 14.2 Billion by 2033, at a CAGR of 11.46% during the forecast period 2023 to 2033.

The aerospace and defense additive manufacturing market is experiencing rapid growth, driven by advancements in 3D printing technology and increasing demand for lightweight, high-strength components. This market encompasses a range of applications, including the production of complex engine parts, airframe structures, and customized components for military and space applications. The benefits of additive manufacturing, such as reduced material waste, shorter production cycles, and the ability to produce intricate designs, are significant drivers for its adoption. Key players in the industry are investing in research and development to enhance the capabilities of additive manufacturing technologies. Additionally, regulatory bodies are developing standards to ensure the quality and reliability of 3D-printed parts, further boosting market confidence and expansion.

Aerospace and Defense Additive Manufacturing Market Value Chain Analysis

The aerospace and defense additive manufacturing market value chain encompasses several critical stages, starting with raw material suppliers who provide specialized metals, polymers, and composites essential for 3D printing. These materials are then processed by technology providers who develop and supply advanced additive manufacturing machines and software. The next stage involves service providers who offer design, prototyping, and production services, leveraging additive manufacturing to create high-performance aerospace and defense components. These components are then tested and validated for compliance with stringent industry standards by quality assurance entities. Finally, the end products are integrated into aircraft, spacecraft, and defense systems by original equipment manufacturers (OEMs), who collaborate with suppliers and regulatory bodies to ensure optimal performance and safety in demanding operational environments.

Aerospace and Defense Additive Manufacturing Market Opportunity Analysis

The aerospace and defense additive manufacturing market presents significant opportunities driven by the demand for innovative, efficient production methods. Additive manufacturing enables the creation of complex, lightweight components, crucial for enhancing fuel efficiency and performance in aerospace and defense applications. The technology's ability to reduce material waste and production time offers cost savings, appealing to both commercial and military sectors. The growing emphasis on customization and rapid prototyping fosters further market expansion, as manufacturers can quickly adapt designs to meet specific requirements. Additionally, advancements in materials and printing technologies open new possibilities for producing durable, high-strength parts. Collaborations between industry leaders and research institutions are accelerating innovation, positioning additive manufacturing as a transformative force in the aerospace and defense industries.

Global Aerospace and Defense Additive Manufacturing Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2023 |

| Market Size in 2023: | USD 4.8 Billion |

| Forecast Period: | 2023-2033 |

| Forecast Period CAGR 2023-2033 : | 11.46% |

| 2033 Value Projection: | USD 14.2 Billion |

| Historical Data for: | 2019-2022 |

| No. of Pages: | 249 |

| Tables, Charts & Figures: | 110 |

| Segments covered: | By Platform, By Vertical, By Application, By Technology, By Region |

| Companies covered:: | General Electric Company, Raytheon Technologies Corporation, The Boeing Company, Lockheed Martin Corporation, Airbus SE, Northrop Grumman Corporation, BAE Systems, Safran SA, Rolls-Royce Holdings, Honeywell Aerospace, Siemens Digital Industries Software, OC Oerlikon Corporation AG, Moog Inc., Aerojet Rocketdyne Holdings Inc., Carpenter Technology Corporation, Renishaw PLC, GKN Aerospace, Stratasys Ltd., EOS GmbH, 3D Systems Corporation, Proto Labs Inc., Materialise NV, Desktop Metal Inc., SLM Solutions Group AG, Optomec Inc., Sintavia, Additive Industries, Optisys LLC, CRP Technology SRL, BeAM Machines Inc., and |

| Pitfalls & Challenges: | COVID-19 Empact, Challenges, Future, Growth, & Analysis |

Get more details on this report -

Market Dynamics

Aerospace and Defense Additive Manufacturing Market Dynamics

Increasing demand for lightweight parts and components will drive market growth

The increasing demand for lightweight parts and components is a major driver of growth in the aerospace and defense additive manufacturing market. Lightweight materials are essential for improving fuel efficiency, reducing emissions, and enhancing the performance of aircraft and defense systems. Additive manufacturing enables the production of intricate, lightweight designs that traditional manufacturing methods cannot achieve, leading to significant weight reductions without compromising strength or durability. This demand is further amplified by the push for more sustainable and cost-effective solutions within the industry. As a result, manufacturers are increasingly adopting 3D printing technologies to produce optimized, high-performance components, driving innovation and expanding the market. The ongoing development of advanced materials and printing techniques continues to enhance the capabilities and appeal of additive manufacturing in aerospace and defense.

Restraints and Challenges

The aerospace and defense additive manufacturing market faces several challenges despite its promising potential. One significant hurdle is the high initial cost of 3D printing equipment and materials, which can be a barrier for widespread adoption, particularly among smaller companies. Additionally, ensuring the quality and reliability of 3D-printed parts is crucial, as these components must meet stringent industry standards and regulatory requirements for safety and performance. There are also technical limitations related to the size and scalability of additive manufacturing processes, restricting the production of larger components. Furthermore, the industry needs to address intellectual property concerns and supply chain complexities. Continuous advancements in technology, standardized certification processes, and collaborative efforts between stakeholders are essential to overcoming these challenges and fully leveraging the benefits of additive manufacturing in aerospace and defense.

Regional Forecasts

North America Market Statistics

Get more details on this report -

North America is anticipated to dominate the Aerospace and Defense Additive Manufacturing Market from 2023 to 2033. The growth is driven by strong technological advancements and significant investments in research and development. The presence of major aerospace and defense companies fosters a robust demand for 3D-printed components to enhance performance and reduce production costs. Government support and funding for defense projects further stimulate market growth, as agencies like NASA and the Department of Defense explore innovative manufacturing techniques. The region's well-established infrastructure and skilled workforce also contribute to the rapid adoption of additive manufacturing technologies. Additionally, collaborations between academic institutions, industry leaders, and research organizations drive continuous innovation, solidifying North America's position as a key player in the global aerospace and defense additive manufacturing market.

Asia Pacific Market Statistics

Asia Pacific is witnessing the fastest market growth between 2023 to 2033. The region's strong manufacturing base and focus on technological advancements foster the adoption of 3D printing for producing lightweight, complex components. Government initiatives supporting research and development, along with collaborations between local firms and global leaders, further boost market growth. Additionally, the expanding commercial aviation sector in Asia-Pacific creates substantial opportunities for integrating additive manufacturing to improve efficiency and cost-effectiveness in aircraft production and maintenance.

Segmentation Analysis

Insights by Platform

The defence segment accounted for the largest market share over the forecast period 2023 to 2033. Additive manufacturing enables the creation of lightweight, durable parts with complex geometries, essential for modern defense applications such as unmanned aerial vehicles (UAVs), missiles, and advanced combat aircraft. The ability to rapidly prototype and produce customized components enhances operational efficiency and adaptability in defense strategies. Additionally, the technology's potential to streamline supply chains and reduce logistical challenges is particularly advantageous in remote or combat environments.

Insights by Vertical

The printer segment is dominating the market with the largest market share over the forecast period 2023 to 2033. The growth is driven by the rising adoption of 3D printing technologies to produce complex, high-performance components. Technological advancements in 3D printers, including improvements in precision, speed, and material capabilities, are making additive manufacturing more viable for aerospace and defense applications. Manufacturers are increasingly investing in advanced printers to produce lightweight, durable parts that meet stringent industry standards. The development of multi-material and metal 3D printers has expanded the range of applications, enabling the production of critical engine parts, airframes, and custom components.

Insights by Application

The space components segment accounted for the largest market share over the forecast period 2023 to 2033. Additive manufacturing offers the ability to produce complex geometries and customized components, which are critical for optimizing performance and reducing the weight of spacecraft. This technology facilitates rapid prototyping and shorter production cycles, allowing for quicker iterations and innovations in space hardware. Key players in the space industry, including NASA and private space companies like SpaceX, are adopting 3D printing to create everything from satellite components to rocket engines. The ability to manufacture parts on-demand in space environments also presents revolutionary possibilities, further driving growth and investment in this segment.

Insights by Technology

The FDM segment is dominating the market with the largest market share over the forecast period 2023 to 2033. FDM technology uses thermoplastic materials, such as ABS and nylon, to build layers of parts, making it ideal for creating lightweight components with good mechanical properties. In aerospace and defense, FDM is utilized for manufacturing drones, tooling, fixtures, and even some structural components of aircraft and spacecraft. The ability to rapidly iterate designs and produce complex geometries without traditional tooling constraints is a major advantage. As FDM printers become more sophisticated and capable of handling high-performance materials, their adoption across the aerospace and defense sectors is expected to continue growing, driving innovation and efficiency in manufacturing processes.

Recent Market Developments

- In February 2021, The United States Department of Defence has secured a USD 1.6 million deal with ExOne for container 3D printing plants. According to the deal, the company will build a 3D printing pod in a normal shipping container up to 40 feet long.

Competitive Landscape

Major players in the market

- General Electric Company

- Raytheon Technologies Corporation

- The Boeing Company

- Lockheed Martin Corporation

- Airbus SE

- Northrop Grumman Corporation

- BAE Systems

- Safran SA

- Rolls-Royce Holdings

- Honeywell Aerospace

- Siemens Digital Industries Software

- OC Oerlikon Corporation AG

- Moog Inc.

- Aerojet Rocketdyne Holdings Inc.

- Carpenter Technology Corporation

- Renishaw PLC

- GKN Aerospace, Stratasys Ltd.

- EOS GmbH

- 3D Systems Corporation

- Proto Labs Inc.

- Materialise NV

- Desktop Metal Inc.

- SLM Solutions Group AG

- Optomec Inc.

- Sintavia

- Additive Industries

- Optisys LLC

- CRP Technology SRL

- BeAM Machines Inc.

Market Segmentation

This study forecasts revenue at global, regional, and country levels from 2023 to 2033.

Aerospace and Defense Additive Manufacturing Market, Platform Analysis

- Aviation

- Aircraft

- UAV

- Defense

- Combat Vehicles

- Military PPE

- Weapons

- Submarine Hulls

- Others

- Space

- Engines

- Satellites

- Spacecraft

- Rockets

Aerospace and Defense Additive Manufacturing Market, Vertical Analysis

- Printer

- Material

- Others

Aerospace and Defense Additive Manufacturing Market, Application Analysis

- Engine Components

- Space Components

- Structural Components

- Defense Equipment

- Others

Aerospace and Defense Additive Manufacturing Market, Technology Analysis

- FDM

- DMLS

- SLA

- CLIP

- SLS

- Others

Aerospace and Defense Additive Manufacturing Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East and Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of Middle East and Africa

Frequently Asked Questions (FAQ)

-

1.What is the market size of the Aerospace and Defense Additive Manufacturing Market?The global Aerospace and Defense Additive Manufacturing Market is expected to grow from USD 4.8 billion in 2023 to USD 14.2 billion by 2033, at a CAGR of 11.46% during the forecast period 2023-2033.

-

2.Who are the key market players of the Aerospace and Defense Additive Manufacturing Market?Some of the key market players of the market are General Electric Company, Raytheon Technologies Corporation, The Boeing Company, Lockheed Martin Corporation, Airbus SE, Northrop Grumman Corporation, BAE Systems, Safran SA, Rolls-Royce Holdings, Honeywell Aerospace, Siemens Digital Industries Software, OC Oerlikon Corporation AG, Moog Inc., Aerojet Rocketdyne Holdings Inc., Carpenter Technology Corporation, Renishaw PLC, GKN Aerospace, Stratasys Ltd., EOS GmbH, 3D Systems Corporation, Proto Labs Inc., Materialise NV, Desktop Metal Inc., SLM Solutions Group AG, Optomec Inc., Sintavia, Additive Industries, Optisys LLC, CRP Technology SRL, BeAM Machines Inc.

-

3.Which segment holds the largest market share?The FDM segment holds the largest market share and is going to continue its dominance.

-

4.Which region is dominating the Aerospace and Defense Additive Manufacturing Market?North America is dominating the Aerospace and Defense Additive Manufacturing Market with the highest market share.

Need help to buy this report?