Global Aerospace Fasteners Market Size, Share, and COVID-19 Impact Analysis, By Product (Rivets, Screws, Nuts & Bolts, and Others), By Material (Aluminum, Steel, Superalloys, and Titanium), By Platform (Fixed-wing Aircraft, Rotary-wing Aircraft), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2023 - 2033

Industry: Aerospace & DefenseGlobal Aerospace Fasteners Market Insights Forecasts to 2033

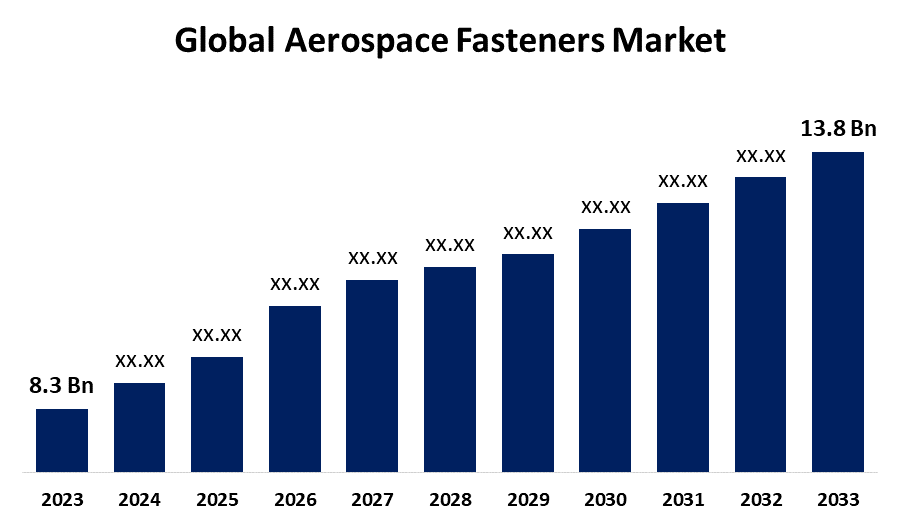

- The Global Aerospace Fasteners Market Size was valued at USD 8.3 Billion in 2023.

- The market is growing at a CAGR of 5.22% from 2023 to 2033.

- The Worldwide Aerospace Fasteners Market Size is expected to reach USD 13.8 Billion by 2033.

- Asia Pacific is expected to grow the fastest during the forecast period.

Get more details on this report -

The Global Aerospace Fasteners Market Size is expected to reach USD 13.8 Billion by 2033, at a CAGR of 5.22% during the forecast period 2023 to 2033.

The global aerospace fasteners market is witnessing significant growth due to rising air travel, increased aircraft production, and growing demand for lightweight, fuel-efficient aircraft. Fasteners are crucial components in the aerospace industry, providing structural integrity and stability to aircraft and spacecraft. The market is segmented into materials such as aluminum, titanium, and alloy steel, with titanium fasteners gaining popularity due to their high strength-to-weight ratio. The commercial aviation segment dominates the market, driven by growing fleet expansions and modernization efforts. Additionally, the defense sector's demand for advanced fighter jets and helicopters further boosts the market. Key players are investing in research and development to introduce innovative fasteners that meet stringent safety standards and improve performance. The Asia-Pacific region is expected to witness the fastest growth, driven by expanding aviation infrastructure.

Aerospace Fasteners Market Value Chain Analysis

The aerospace fasteners market value chain comprises several stages, from raw material procurement to the end-user application. It begins with raw material suppliers, providing aluminum, titanium, and steel alloys essential for manufacturing fasteners. Manufacturers then design and produce various fastener types, such as bolts, nuts, screws, and rivets, ensuring compliance with stringent aerospace standards. After production, these fasteners undergo rigorous quality testing before being supplied to distributors or directly to aircraft manufacturers and maintenance, repair, and overhaul (MRO) service providers. The integration of fasteners is crucial in aircraft assembly, where they ensure structural integrity and safety. The value chain is supported by logistics and supply chain management, ensuring timely delivery and compliance with global aviation regulations. Advanced technologies and digital platforms are enhancing efficiency and traceability across the value chain.

Aerospace Fasteners Market Opportunity Analysis

The aerospace fasteners market presents numerous growth opportunities driven by increasing aircraft production, rising air traffic, and fleet modernization initiatives. With a focus on lightweight and fuel-efficient aircraft, the demand for advanced fasteners made from high-strength materials like titanium and composites is expanding. Emerging markets in Asia-Pacific, the Middle East, and Latin America are seeing increased investments in aviation infrastructure, creating new growth avenues. Additionally, the rise in space exploration activities and commercial space ventures boosts the need for specialized fasteners. The aftermarket segment, including maintenance, repair, and overhaul (MRO), also offers significant opportunities as airlines seek to extend aircraft lifecycles. Innovations in 3D printing and additive manufacturing technologies further present growth potential by enabling the production of complex and customized fastener designs.

Global Aerospace Fasteners Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2023 |

| Market Size in 2023: | USD 8.3 Billion |

| Forecast Period: | 2023-2033 |

| Forecast Period CAGR 2023-2033 : | 5.22% |

| 2033 Value Projection: | USD 13.8 Billion |

| Historical Data for: | 2019-2022 |

| No. of Pages: | 250 |

| Tables, Charts & Figures: | 110 |

| Segments covered: | By Product, By Material, By Platform, and By Region |

| Companies covered:: | 3V Fasteners Company, Inc., Acument Global Technologies, Arconic Fastening Systems & Rings, B&B Specialties, Inc., Boeing Distribution Services Inc., HC Merchandisers, Inc., Howmet Aerospace Inc., LISI Aerospace, MS Aerospace, National Aerospace Fasteners Corporation, PCC Fasteners, Stanley Black & Decker, Inc., Stanley Engineered Fastening, TFI Aerospace Corporation, TPS Aviation, Inc., TriMas Corporation, and Wurth Group |

| Pitfalls & Challenges: | COVID-19 Empact, Challenge, Future, Growth, & Analysis |

Get more details on this report -

Market Dynamics

Aerospace Fasteners Market Dynamics

Innovation and technological developments in the aircraft industry

Innovation and technological advancements in the aircraft industry are key drivers of growth in the aerospace fasteners market. The shift towards lightweight, fuel-efficient aircraft has increased the demand for advanced fasteners made from high-performance materials like titanium, composites, and superalloys, which offer enhanced strength-to-weight ratios and corrosion resistance. The adoption of automation and robotics in manufacturing processes has improved precision and efficiency in fastener production. Additionally, advancements in 3D printing and additive manufacturing enable the creation of complex, customized fasteners, reducing production lead times and costs. Innovations in coatings and surface treatments enhance fastener durability, meeting stringent safety standards. Furthermore, the development of self-locking and vibration-resistant fasteners contributes to overall aircraft safety and performance, making these components integral to modern aircraft design and engineering.

Restraints & Challenges

Stringent regulatory standards and compliance requirements pose a major hurdle for manufacturers, as these fasteners must meet rigorous safety and performance criteria. The high cost of raw materials, especially for titanium and superalloys, contributes to fluctuating production costs, affecting profit margins. Supply chain disruptions, such as material shortages and logistical delays, further complicate market dynamics, particularly in the wake of geopolitical tensions and global events. Additionally, the market is highly competitive, with established players investing heavily in R&D, making it difficult for smaller firms to sustain profitability. Technological advancements like additive manufacturing also present a dual-edged sword, as they require significant investment in new capabilities, which may be beyond the reach of many traditional fastener manufacturers.

Regional Forecasts

North America Market Statistics

Get more details on this report -

North America is anticipated to dominate the Aerospace Fasteners Market from 2023 to 2033. The region benefits from high defense spending and strong demand for commercial and business jets, which bolsters the need for advanced fasteners. Additionally, technological innovations and a focus on lightweight, fuel-efficient aircraft are driving the adoption of high-strength fasteners made from titanium and composite materials. The market also benefits from the region’s well-established MRO (maintenance, repair, and overhaul) sector, which generates consistent demand for fasteners. However, supply chain challenges and raw material price volatility could impact growth. Despite this, North America remains a key market for innovation and production of aerospace fasteners globally.

Asia Pacific Market Statistics

Asia Pacific is witnessing the fastest market growth between 2023 to 2033. Countries like China, India, and Japan are leading the demand due to significant investments in aviation infrastructure and fleet expansion. The region’s growing presence in aircraft manufacturing, particularly with companies like COMAC in China, is further boosting the demand for aerospace fasteners. Additionally, the rise of low-cost carriers and the development of new airports support market growth. With a focus on lightweight and fuel-efficient aircraft, demand for advanced fasteners made from titanium and composites is increasing. However, challenges such as regulatory compliance, supply chain inefficiencies, and reliance on imports for raw materials could impact the overall growth trajectory of the Asia-Pacific aerospace fasteners market.

Segmentation Analysis

Insights by Product

The rivets segment accounted for the largest market share over the forecast period 2023 to 2033. Rivets are preferred for joining aluminum and other lightweight materials, offering high shear strength, durability, and reliability in high-stress environments. The increasing production of commercial and military aircraft, along with rising demand for lightweight, fuel-efficient designs, has led to higher adoption of advanced rivets made from titanium and composites. Technological advancements, such as blind rivets and self-piercing variants, enhance efficiency and reduce installation time, further driving their popularity. The segment also benefits from the growing maintenance, repair, and overhaul (MRO) activities, as rivets are commonly replaced during structural repairs.

Insights by Material

The titanium segment accounted for the largest market share over the forecast period 2023 to 2033. Titanium fasteners are increasingly used in both commercial and military aircraft to reduce overall weight and improve fuel efficiency, contributing to lower operating costs and emissions. The growing production of next-generation aircraft, such as the Boeing 787 and Airbus A350, which incorporate more composite materials, has further boosted demand for titanium fasteners. Moreover, as the aerospace industry focuses on developing supersonic and electric aircraft, titanium’s superior mechanical properties are critical for ensuring structural integrity under extreme conditions. Despite higher costs compared to traditional materials, the benefits of titanium fasteners make them indispensable for modern aircraft design and engineering.

Insights by Platform

The fixed wing segment accounted for the largest market share over the forecast period 2023 to 2033. As air travel demand rises, manufacturers are ramping up the production of narrow-body and wide-body aircraft, driving the need for reliable and high-performance fasteners. Technological advancements, such as the development of lightweight, high-strength materials, further enhance the segment's growth. Additionally, the expansion of the global defense sector and modernization programs for existing aircraft fleets are bolstering demand. This segment's growth is particularly strong in North America and Europe, key hubs for aircraft manufacturing and assembly.

Recent Market Developments

- In February 2023, An Indian airline, Air India, increased the size of its fleet by placing orders for more than 800 jump engines for more than 200 Boeing 737 Max and Airbus A320/A321neo aircraft. Since Air India has been a distinguished partner of CFM since 2002, the airlines have inked a deal for the same kind of trust-building.

Competitive Landscape

Major players in the market

- 3V Fasteners Company, Inc.

- Acument Global Technologies

- Arconic Fastening Systems & Rings

- B&B Specialties, Inc.

- Boeing Distribution Services Inc.

- HC Merchandisers, Inc.

- Howmet Aerospace Inc.

- LISI Aerospace

- MS Aerospace

- National Aerospace Fasteners Corporation

- PCC Fasteners

- Stanley Black & Decker, Inc.

- Stanley Engineered Fastening

- TFI Aerospace Corporation

- TPS Aviation, Inc.

- TriMas Corporation

- Wurth Group

Market Segmentation

This study forecasts revenue at global, regional, and country levels from 2023 to 2033.

Aerospace Fasteners Market, Product Analysis

- Rivets

- Screws

- Nuts & Bolts

- Others

Aerospace Fasteners Market, Material Analysis

- Aluminum

- Steel

- Superalloys

- Titanium

Aerospace Fasteners Market, Platform Analysis

- Fixed-wing Aircraft

- Rotary-wing Aircraft

Aerospace Fasteners Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

Frequently Asked Questions (FAQ)

-

1. What is the market size of the Aerospace Fasteners Market?The global Aerospace Fasteners Market is expected to grow from USD 8.3 billion in 2023 to USD 13.8 billion by 2033, at a CAGR of 5.22% during the forecast period 2023-2033.

-

2. Who are the key market players of the Aerospace Fasteners Market?Some of the key market players of the market are 3V Fasteners Company, Inc., Acument Global Technologies, Arconic Fastening Systems & Rings, B&B Specialties, Inc., Boeing Distribution Services Inc., HC Merchandisers, Inc., Howmet Aerospace Inc., LISI Aerospace, MS Aerospace, National Aerospace Fasteners Corporation, PCC Fasteners, Stanley Black & Decker, Inc., Stanley Engineered Fastening, TFI Aerospace Corporation, TPS Aviation, Inc., TriMas Corporation, Wurth Group.

-

3. Which segment holds the largest market share?The rivets segment holds the largest market share and is going to continue its dominance.

-

4. Which region dominates the Aerospace Fasteners Market?North America dominates the Aerospace Fasteners Market and has the highest market share.

Need help to buy this report?