Global Aerospace Metal Closed-die Forging Market Size, Share, and COVID-19 Impact Analysis, By Product (<10000 MT Press Capacity, 10000-19000 MT Press Capacity, 20000-29000 MT Press Capacity), By Application (Engine Components, Landing Gear and Structural Components, Helicopter Rotor Components and Shafts), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2023 - 2033

Industry: Aerospace & DefenseGlobal Aerospace Metal Closed-die Forging Market Insights Forecasts to 2033

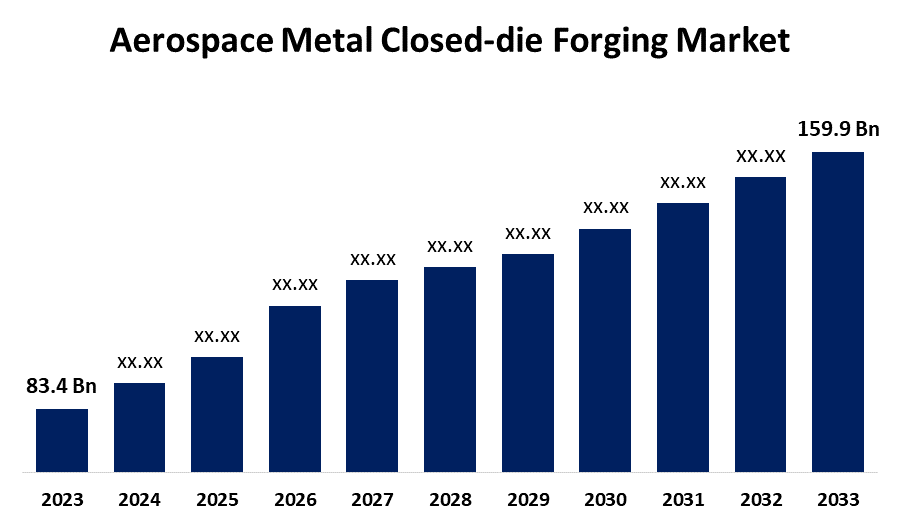

- The Aerospace Metal Closed-die Forging Market was valued at USD 83.4 billion in 2023.

- The market Size is growing at a CAGR of 6.73% from 2023 to 2033.

- The global Aerospace Metal Closed-die Forging Market is expected to reach USD 159.9 Billion by 2033.

- Asia Pacific is expected to grow the fastest during the forecast period.

Get more details on this report -

The global Aerospace Metal Closed-die Forging Market Size is expected to reach USD 159.9 Billion by 2033, at a CAGR of 6.73% during the forecast period 2023 to 2033.

The aerospace metal closed-die forging market is a specialized sector driven by the demand for high-strength, lightweight components for aircraft and aerospace applications. Closed-die forging is preferred in aerospace for producing precision parts, such as engine components, landing gear, and structural frames, offering enhanced mechanical properties and structural integrity. Key materials include titanium, aluminum, and steel alloys, chosen for their high strength-to-weight ratios and corrosion resistance. The industry is experiencing growth due to rising air travel, increased military investments, and the expanding space exploration sector. Advanced forging technologies, including automation and 3D modeling, are improving production efficiencies and quality. Leading companies in the market focus on innovation to meet stringent industry standards, catering to both commercial and defense segments globally.

Aerospace Metal Closed-die Forging Market Value Chain Analysis

The aerospace metal closed-die forging market value chain begins with raw material suppliers, providing high-quality alloys like titanium, aluminum, and steel to ensure the durability and performance needed in aerospace applications. These materials are then transformed through forging by manufacturers, who use advanced closed-die techniques to produce precisely shaped, high-strength parts like turbine disks, landing gears, and structural frames. Manufacturers work closely with engineering teams to meet strict aerospace standards, such as AS9100, ensuring quality control and adherence to regulatory guidelines. After forging, components are often machined and treated to enhance strength and corrosion resistance before assembly. Distributors and logistics firms manage supply chains, delivering these components to OEMs and maintenance, repair, and overhaul (MRO) providers who integrate them into commercial, military, and space aerospace systems.

Aerospace Metal Closed-die Forging Market Opportunity Analysis

The aerospace metal closed-die forging market presents significant growth opportunities, driven by rising demand for lightweight, durable components in commercial, defense, and space sectors. Increasing air travel and a surge in defense spending globally fuel demand for forged parts that withstand extreme conditions and stress. The shift toward lightweight materials, particularly titanium and aluminum, offers opportunities for suppliers and manufacturers as aerospace firms seek to improve fuel efficiency and reduce emissions. Additionally, advancements in automation, precision forging, and AI-based quality control create opportunities to increase efficiency and reduce waste, driving cost-effectiveness. Emerging markets, particularly in Asia-Pacific and the Middle East, are expected to contribute robustly, as they ramp up their aerospace manufacturing capabilities, presenting new avenues for partnerships and supply chain expansions.

Aerospace Metal Closed-die Forging Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2023 |

| Market Size in 2023: | USD 83.4 Billion |

| Forecast Period: | 2023-2033 |

| Forecast Period CAGR 2023-2033 : | 6.73% |

| 2033 Value Projection: | USD 159.9 Billion |

| Historical Data for: | 2019-2022 |

| No. of Pages: | 255 |

| Tables, Charts & Figures: | 125 |

| Segments covered: | By Product, By Application, and By Region |

| Companies covered:: | Arconic (U.S.),ATI (Canada),Bharat Forge (India),ELLWOOD Group Inc (U.S.),JIANGYIN HENGRUN HEAVY INDUSTRIES CO., LTD (China),Precision Castparts Corp (U.S.),LARSEN & TOUBRO LIMITED (India),Scot Forge Company (U.S.) Pacific Forge Incorporated (U.S.),Somers Forge (U.K.),eramet (France),VSMPO-AVISMA Corporation (Russia),ALL METALS & FORGE GROUP (U.S.),Consolidated Industries, Inc (U.S.),Farinia (U.S.),Mettis Group (U.S.) |

| Pitfalls & Challenges: | COVID-19 Empact, Challenge, Future, Growth, & Analysis |

Get more details on this report -

Market Dynamics

Aerospace Metal Closed-die Forging Market Dynamics

The rise in local and international travel to propel the market growth

The aerospace metal closed-die forging market is poised for growth, fueled by increasing local and international air travel. This rise in travel drives demand for new commercial aircraft and fleet expansions, as airlines seek to accommodate more passengers and enhance operational efficiency. To support growing fleets, the need for durable, high-performance forged components—such as turbine disks, landing gear, and structural parts—escalates, particularly as these parts contribute to fuel efficiency and safety. Additionally, increasing investments in defense and space exploration amplify demand for lightweight, corrosion-resistant materials like titanium and aluminum in aircraft production. With the expansion of travel networks in emerging markets, particularly in Asia-Pacific, the demand for advanced forged aerospace components is expected to continue rising, strengthening the market globally.

Restraints & Challenges

The aerospace metal closed-die forging market faces several challenges that could impact its growth. High production costs, driven by the expense of raw materials like titanium and aluminum alloys, challenge manufacturers striving to maintain profitability. Stringent industry standards and certifications, such as AS9100, require rigorous quality control and adherence, leading to increased operational costs and potential delays. Additionally, the forging process itself is energy-intensive, making it susceptible to fluctuations in energy prices and environmental regulations, especially as the industry seeks to reduce its carbon footprint. Supply chain disruptions, exacerbated by global economic conditions and geopolitical tensions, pose risks to material availability and lead times. Moreover, competition from alternative manufacturing methods, like additive manufacturing, adds pressure for innovation and efficiency in traditional forging practices.

Regional Forecasts

North America Market Statistics

Get more details on this report -

North America is anticipated to dominate the Aerospace Metal Closed-die Forging Market from 2023 to 2033. The U.S. leads the market with its extensive demand for high-strength, lightweight forged components used in both commercial aviation and military aircraft. Major aerospace companies like Boeing and Lockheed Martin drive demand for precise, durable components forged from materials such as titanium and aluminum. Stringent safety regulations and a focus on fuel efficiency further increase demand for advanced forging processes that produce lighter, stronger components. Canada also contributes, with growing investments in aerospace manufacturing and maintenance, repair, and overhaul (MRO) services. The ongoing focus on innovation and increasing investments in defense by the U.S. government support steady growth in the North American market.

Asia Pacific Market Statistics

Asia Pacific is witnessing the fastest market growth between 2023 to 2033. Governments across the region are investing heavily in aerospace manufacturing capabilities, aiming to support both domestic and international commercial aviation. This growth drives the demand for high-strength forged components, such as engine parts and landing gear, made from lightweight materials like titanium and aluminum to improve fuel efficiency and performance. Additionally, rising defense budgets in countries such as China and India bolster the need for robust, high-quality components for military aircraft. Key aerospace companies are forming partnerships and setting up facilities in the region to leverage cost advantages, skilled labor, and strong demand for aerospace innovation.

Segmentation Analysis

Insights by Product

The 10000-19000 MT Press Capacity segment accounted for the largest market share over the forecast period 2023 to 2033. This press capacity allows manufacturers to produce high-strength, precision components, such as engine parts, landing gears, and airframe structures, essential for both commercial and military aircraft. Demand in this segment is bolstered by the growing emphasis on lightweight, durable components to enhance fuel efficiency and reduce emissions. The 10,000–19,000 MT range offers an ideal balance of operational efficiency and cost-effectiveness, making it popular among manufacturers aiming to scale production without incurring the high operational costs of ultra-heavy-duty presses. Emerging aerospace markets, especially in Asia-Pacific, are further contributing to this segment's growth as they expand their aerospace manufacturing capacities.

Insights by Application

The engine components segment accounted for the largest market share over the forecast period 2023 to 2033. As global air travel continues to increase, airlines and manufacturers are focusing on producing more fuel-efficient and reliable engines, necessitating advanced forging techniques to create high-strength, lightweight parts. Closed-die forging allows for the precise manufacturing of critical components, such as turbine disks, blades, and shafts, which must endure extreme temperatures and pressures. Moreover, advancements in materials technology, particularly the use of titanium and high-performance alloys, enhance the durability and efficiency of these components. The ongoing innovations in engine design and technology, coupled with stringent safety regulations, further propel the growth of this segment, solidifying its importance in the aerospace industry.

Recent Market Developments

- On July 2022, Patriot Forge has announced plans to enhance its open-die custom forging manufacturing plant by adding a comprehensive rough machining process to its forging facilities.

Competitive Landscape

Major players in the market

- Arconic (U.S.)

- ATI (Canada)

- Bharat Forge (India)

- ELLWOOD Group Inc (U.S.)

- JIANGYIN HENGRUN HEAVY INDUSTRIES CO., LTD (China)

- Precision Castparts Corp (U.S.)

- LARSEN & TOUBRO LIMITED (India)

- Scot Forge Company (U.S.) Pacific Forge Incorporated (U.S.)

- Somers Forge (U.K.)

- eramet (France)

- VSMPO-AVISMA Corporation (Russia)

- ALL METALS & FORGE GROUP (U.S.)

- Consolidated Industries, Inc (U.S.)

- Farinia (U.S.)

- Mettis Group (U.S.)

Market Segmentation

This study forecasts revenue at global, regional, and country levels from 2023 to 2033.

Aerospace Metal Closed-die Forging Market, Product Analysis

- <10000 MT Press Capacity

- 10000-19000 MT Press Capacity

- 20000-29000 MT Press Capacity

Aerospace Metal Closed-die Forging Market, Application Analysis

- Engine Components

- Landing Gear and Structural Components

- Helicopter Rotor Components and Shafts

Aerospace Metal Closed-die Forging Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

Frequently Asked Questions (FAQ)

-

1. What is the market size of the Aerospace Metal Closed-die Forging Market?The global Aerospace Metal Closed-die Forging Market is expected to grow from USD 83.4 billion in 2023 to USD 159.9 billion by 2033, at a CAGR of 6.73% during the forecast period 2023-2033.

-

2. Who are the key market players of the Aerospace Metal Closed-die Forging Market?Some of the key market players of the market are Arconic (U.S.), ATI (Canada), Bharat Forge (India), ELLWOOD Group Inc (U.S.), JIANGYIN HENGRUN HEAVY INDUSTRIES CO., LTD (China), Precision Castparts Corp (U.S.), LARSEN & TOUBRO LIMITED (India), Scot Forge Company (U.S.) Pacific Forge Incorporated (U.S.), Somers Forge (U.K.), eramet (France), VSMPO-AVISMA Corporation (Russia), ALL METALS & FORGE GROUP (U.S.), Consolidated Industries, Inc (U.S.), Farinia (U.S.), Mettis Group (U.S.).

-

3. Which segment holds the largest market share?The engine components segment holds the largest market share and is going to continue its dominance.

-

4. Which region dominates the Aerospace Metal Closed-die Forging Market?North America dominates the Aerospace Metal Closed-die Forging Market and has the highest market share.

Need help to buy this report?