Global Aerospace Titanium Machining Market Size, Share, and COVID-19 Impact Analysis, By Type(Titanium Alloys, and Commercially Pure Titanium), By Application(Structural Airframes, Engines, and Others), By Manufacturing Process(Casting, Powder Metallurgy, Machining), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2023 - 2033

Industry: Aerospace & DefenseGlobal Aerospace Titanium Machining Market Insights Forecasts to 2033

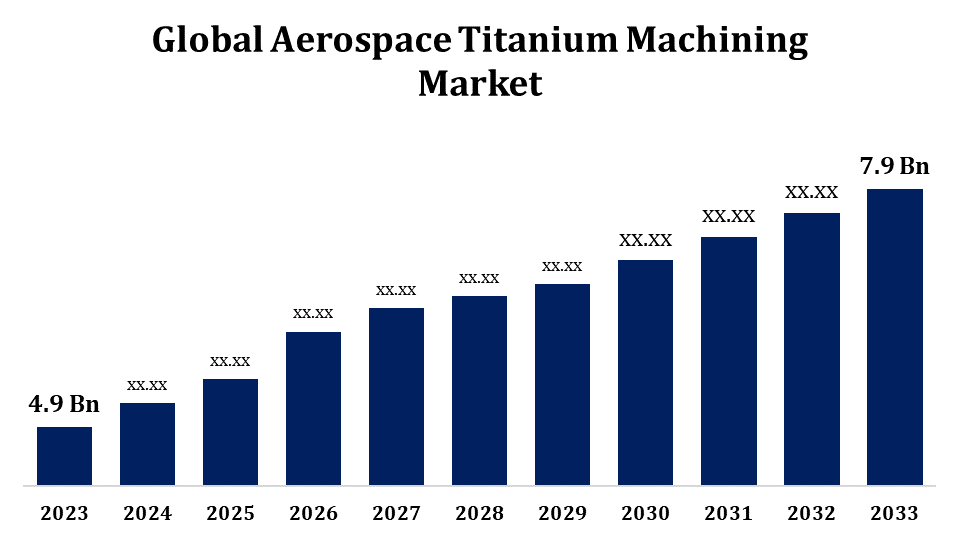

- The Aerospace Titanium Machining Market Size was valued at USD 4.9 Billion in 2023.

- The Market Size is Growing at a CAGR of 4.89% from 2023 to 2033.

- The Worldwide Aerospace Titanium Machining Market Size is Expected to reach USD 7.9 Billion by 2033.

- Asia Pacific is Expected to Grow the fastest during the forecast period.

Get more details on this report -

The Global Aerospace Titanium Machining Market Size is Expected to reach USD 7.9 Billion by 2033, at a CAGR of 4.89% during the forecast period 2023 to 2033.

The aerospace titanium machining market is a critical segment within the broader aerospace industry, driven by the increasing demand for lightweight, high-strength materials in aircraft manufacturing. Titanium, known for its exceptional strength-to-weight ratio, corrosion resistance, and ability to withstand extreme temperatures, has become a preferred material for various aerospace components, including airframes, engines, and landing gear. The market has seen significant growth due to advancements in machining technologies, which enhance precision and efficiency in processing titanium alloys. Additionally, the rise in air travel and the ongoing development of fuel-efficient aircraft are propelling the demand for titanium components. Major players in this market are investing in research and development to innovate machining processes and improve material yield, thereby reducing costs and environmental impact. Furthermore, the increasing focus on sustainability and regulatory compliance in the aerospace sector is driving the adoption of titanium machining solutions that minimize waste and energy consumption. Overall, the aerospace titanium machining market is poised for continued expansion, fueled by technological advancements, increasing aircraft production, and a growing emphasis on sustainable practices.

Aerospace Titanium Machining Market Value Chain Analysis

The aerospace titanium machining market value chain comprises several key stages: raw material sourcing, processing, machining, finishing, and distribution. Initially, high-quality titanium alloys are sourced from suppliers, ensuring compliance with industry standards. In the processing stage, these materials undergo treatments to enhance their properties. Next, specialized machining techniques, such as CNC machining and additive manufacturing, shape the titanium components with precision. The finishing stage includes surface treatments and coatings to improve performance and durability. Finally, finished products are distributed to aerospace manufacturers and suppliers. Throughout the value chain, collaboration and innovation play crucial roles in optimizing processes, reducing waste, and ensuring quality control, ultimately meeting the stringent demands of the aerospace industry.

Aerospace Titanium Machining Market Opportunity Analysis

The aerospace titanium machining market presents significant opportunities driven by several factors. First, the increasing demand for lightweight and fuel-efficient aircraft enhances the need for titanium components, known for their strength-to-weight ratio. Additionally, advancements in machining technologies, such as 3D printing and automated processes, enable manufacturers to produce intricate designs with greater efficiency and precision. The growing focus on sustainability and regulatory compliance further incentivizes the use of titanium, which is more environmentally friendly compared to traditional materials. Emerging markets, particularly in Asia-Pacific, are witnessing rapid growth in air travel, creating further demand for aerospace components. Finally, the ongoing push for innovation in aerospace design and manufacturing opens avenues for companies to develop specialized machining solutions, catering to the evolving needs of the industry.

Global Aerospace Titanium Machining Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2023 |

| Market Size in 2023: | USD 4.9 Billion |

| Forecast Period: | 2023-2033 |

| Forecast Period CAGR 2023-2033 : | 4.89% |

| 2033 Value Projection: | USD 4.9 Billion |

| Historical Data for: | 2019-2022 |

| No. of Pages: | 229 |

| Tables, Charts & Figures: | 110 |

| Segments covered: | By Type, By Application, By Manufacturing Process, By Region |

| Companies covered:: | Kennametal, Sandvik Coromant, Maniko, Protolabs, Universal Metal, Dynamic Metal, FPD Company, Ural Boeing Manufacturing, Others , and Others |

| Pitfalls & Challenges: | Covid-19 Empact, Challenges, Growth, Analysis. |

Get more details on this report -

Market Dynamics

Aerospace Titanium Machining Market Dynamics

Increasing Titanium Use in the Production of Lightweight Aircraft

The aerospace industry is increasingly adopting titanium in the production of lightweight aircraft due to its exceptional strength-to-weight ratio, corrosion resistance, and high-temperature performance. As manufacturers seek to enhance fuel efficiency and reduce emissions, titanium’s lightweight properties make it an ideal choice for critical components such as airframes, engines, and landing gear. The machining of titanium has evolved, with advancements in technologies like CNC machining and additive manufacturing enabling the production of complex geometries with precision. This shift towards lightweight designs not only improves aircraft performance but also contributes to sustainability goals by decreasing overall fuel consumption. Consequently, the demand for titanium machining services is rising, presenting significant opportunities for growth in the aerospace titanium machining market.

Restraints & Challenges

The aerospace titanium machining market faces several challenges that impact growth and operational efficiency. One significant challenge is the high cost of titanium materials, which can restrict budget allocation for manufacturers. Additionally, machining titanium is technically demanding due to its unique properties, including toughness and heat sensitivity, leading to increased wear on tools and requiring specialized machining techniques that can raise production costs. Moreover, there is a shortage of skilled labor proficient in advanced machining processes, hindering efficiency and quality. Regulatory compliance and stringent industry standards further complicate the manufacturing process, necessitating continuous investment in quality assurance. Finally, fluctuations in demand driven by geopolitical factors and economic conditions can create uncertainty, making it difficult for companies to plan and optimize their operations effectively.

Regional Forecasts

North America Market Statistics

North America is anticipated to dominate the Aerospace Titanium Machining Market from 2023 to 2033. Major companies in the U.S. and Canada are increasingly utilizing titanium due to its lightweight and high-strength properties, which are essential for producing advanced aircraft. The market benefits from significant investments in research and development, focusing on innovative machining technologies that enhance efficiency and reduce production costs. Additionally, the rising demand for fuel-efficient and environmentally friendly aircraft aligns with the growing trend of incorporating titanium into aircraft design. North America also boasts a skilled workforce and established supply chains, further supporting market growth. However, challenges such as high material costs and stringent regulatory requirements continue to shape the competitive landscape in this region.

Asia Pacific Market Statistics

Get more details on this report -

Asia Pacific is witnessing the fastest market growth between 2023 to 2033. Countries like China, India, and Japan are investing heavily in aircraft manufacturing and maintenance, fostering a rising need for lightweight and durable titanium components. The region benefits from advancements in machining technologies, including automated processes and additive manufacturing, which enhance production efficiency and precision. Additionally, local manufacturers are increasingly adopting titanium for its favorable properties, contributing to sustainability efforts by reducing fuel consumption in aircraft. However, the market faces challenges such as limited access to high-quality titanium and the need for skilled labor. Despite these obstacles, the Asia-Pacific region presents significant opportunities for growth, supported by a favorable regulatory environment and government initiatives promoting aerospace development.

Segmentation Analysis

Insights by Type

The titanium alloys segment accounted for the largest market share over the forecast period 2023 to 2033. Alloys such as Ti-6Al-4V, known for their excellent strength-to-weight ratio and corrosion resistance, are increasingly used in critical aircraft components like airframes and engine parts. This growing preference is driven by the aerospace industry's demand for lightweight materials that enhance fuel efficiency and reduce emissions. Advances in machining technologies are enabling the efficient processing of titanium alloys, addressing challenges such as tool wear and machining difficulty. Furthermore, the ongoing focus on innovation and sustainability in aerospace design fosters the adoption of titanium alloys. As manufacturers strive for enhanced performance and compliance with environmental regulations, the titanium alloys segment is poised for continued growth in the aerospace titanium machining market.

Insights by Application

The structural airframes segment accounted for the largest market share over the forecast period 2023 to 2033. Titanium’s high strength-to-weight ratio, corrosion resistance, and ability to withstand extreme temperatures make it an ideal choice for airframe components. As the aerospace industry focuses on improving fuel efficiency and overall aircraft performance, the use of titanium in structural airframes has gained traction. Advanced machining technologies, such as precision CNC machining and additive manufacturing, are enhancing the production capabilities for complex airframe designs, allowing manufacturers to optimize material use and reduce waste. Additionally, the push for sustainable aviation practices further supports the growth of this segment, as titanium’s recyclability aligns with environmental goals, making it a preferred material in modern aircraft design.

Insights by Manufacturing Process

The casting segment accounted for the largest market share over the forecast period 2023 to 2033. Titanium castings offer excellent mechanical properties, lightweight characteristics, and resistance to high temperatures and corrosion, making them ideal for various aerospace applications. As manufacturers strive for enhanced design flexibility and reduced production costs, advanced casting techniques, such as investment casting and sand casting, are becoming more prevalent. These methods allow for the creation of intricate geometries that are challenging to achieve through traditional machining. Furthermore, the growing focus on lightweight structures in aircraft design is propelling the demand for titanium castings, as they contribute to improved fuel efficiency and overall performance. With ongoing innovations in casting technology and materials, this segment is poised for continued expansion in the aerospace titanium machining market.

Recent Market Developments

- In May 2023, Kennametal Inc. has announced that its HARVI™ solid carbide end mills will be recognized as a preferred product in Lockheed Martin's internal machining guide. This resource, created by the Operations Technology division of Lockheed Martin Aeronautics in collaboration with global supply chain partners, outlines the best machining parameters and processes tailored for aerospace components based on specific materials.

Competitive Landscape

Major players in the market

- Kennametal

- Sandvik Coromant

- Maniko, Protolabs

- Universal Metal

- Dynamic Metal

- FPD Company

- Ural Boeing Manufacturing

- Others

Market Segmentation

This study forecasts revenue at global, regional, and country levels from 2023 to 2033.

Aerospace Titanium Machining Market, Type Analysis

- Titanium Alloys

- Commercially Pure Titanium

Aerospace Titanium Machining Market, Application Analysis

- Structural Airframes

- Engines

- Others

Aerospace Titanium Machining Market, Manufacturing Process Analysis

- Casting

- Powder Metallurgy

- Machining

Aerospace Titanium Machining Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

Frequently Asked Questions (FAQ)

-

1.What is the market size of the Aerospace Titanium Machining Market?The global Aerospace Titanium Machining Market is expected to grow from USD 4.9 billion in 2023 to USD 7.9 billion by 2033, at a CAGR of 4.89% during the forecast period 2023-2033.

-

2.Who are the key market players of the Aerospace Titanium Machining Market?Some of the key market players of the market are Kennametal, Sandvik Coromant, Maniko, Protolabs, Universal Metal, Dynamic Metal, FPD Company, Ural Boeing Manufacturing.

-

3.Which segment holds the largest market share?The titanium alloys segment holds the largest market share and is going to continue its dominance.

-

4.Which region dominates the Aerospace Titanium Machining Market?North America dominates the Aerospace Titanium Machining Market and has the highest market share.

Need help to buy this report?