Global CNC Work Holding Product Market Size, Share, and COVID-19 Impact Analysis, By Product Type (Chucks, Clamps, Vices, Fixtures, and Others), By Application (Automotive Industry, Aerospace Industry, Medical Devices, Industrial Equipment, and Others), and By Region (North America, Europe, Asia Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2023 - 2033

Industry: Machinery & EquipmentGlobal CNC Work Holding Product Market Insights Forecasts to 2033

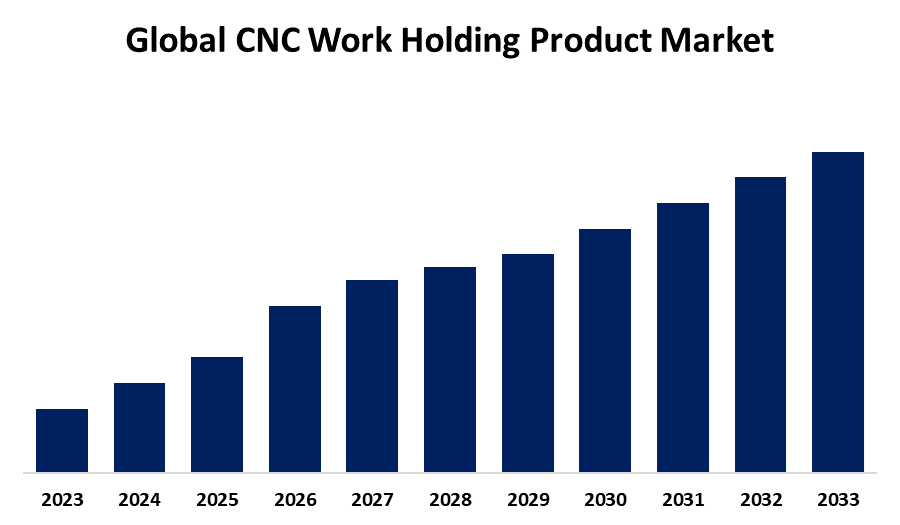

- The Market Size is Growing at a CAGR of 4.1% from 2023 to 2033

- The Worldwide CNC Work Holding Product Market Size is Expected to Hold a Significant Share by 2033

- North America is expected to grow the fastest during the forecast period.

Get more details on this report -

The CNC work holding product market is growing with rising demand for precision manufacturing. Gains in automation, high-quality materials, and the requirement for efficient, customizable solutions boost growth. Key sectors are automotive, aerospace, and electronics that help foster market innovation and competition.

Market Overview

The CNC work holding product market is the industry segment that deals with designing, producing, and selling tools and equipment to hold and secure workpieces in place during CNC machining processes. These work holding products are critical for ensuring precision, stability, and efficiency during the manufacturing of parts in industries such as automotive, aerospace, medical, electronics, and industrial machinery. Moreover, CNC work holding market is experiencing growth because of automation, robotics, and smart work holding systems integrated with IoT for real-time monitoring. Quick-change systems cut downtime while 3D-printed solutions offer customization in a low-cost package. Industry-specific demand for automotive, aerospace, medical devices, and electronics is picking up as companies demand high-precision components. Customization is becoming increasingly the norm, which pushes the demand for flexible and modular fixtures for companies to deal with diversified and complex machining requirements in their operations. Furthermore, opportunities in the CNC work holding market include advances in AI-driven automation, growing demand for flexible and adaptive systems, and lightweight materials. Trends include a shift towards energy-efficient solutions, seamless integration with IoT, and the growth of customized work holding products.

Report Coverage

This research report categorizes the global CNC work holding product market based on various segments and regions forecasts revenue growth and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the global CNC work holding product market. Recent market developments and competitive strategies such as expansion, product launch, and development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the global CNC work holding product market.

Global CNC Work Holding Product Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2023 |

| Forecast Period: | 2023 – 2033 |

| Forecast Period CAGR 2023 – 2033 : | 4.1% |

| Historical Data for: | 2021-2022 |

| No. of Pages: | 200 |

| Tables, Charts & Figures: | 120 |

| Segments covered: | By Application, By Product Type and By Region |

| Companies covered:: | Gerardi SPA, EROWA, CPWS, 5th Axis, TE-CO Manufacturing, Elijah Tooling, DMT Workholding, Jergens, Positrol, LMC Workholding, Norgren (IMI), Forkardt, Others |

| Pitfalls & Challenges: | COVID-19 Empact, Challenge, Future, Growth, & Analysis |

Get more details on this report -

Driving Factors

The key driving factors of the CNC work holding market are the increasing demand for automation and precision manufacturing, advancements in smart technology with IoT integration, the need for rapid production and reduced downtime, and the rise of customized and modular work holding solutions. Industry growth in sectors such as automotive, aerospace, and medical devices also drive the need for advanced, efficient work holding systems. Moreover, In June 2023, Makino Milling Machine Co., Ltd. launched the A91NX horizontal machining center. The latest product in the company's popular NX-series lineup will bring advanced capabilities to machining oversized components. With high-quality machining results and outstanding thruput capabilities, along with overall manufacturing costs, this machine is very suitable for use in applications such as automotive, industrial components, agriculture equipment, construction machinery, and aero structural pieces.

Restraints & Challenges

The CNC work holding market suffers from problems such as expensive high-end systems, intricate integration with existing equipment, and a lack of skilled workers. Maintenance and durability of high-end systems may incur more long-term costs, while highly customized solutions add time and cost to production.

Market Segmentation

The global CNC work holding product market share is classified into product type and application.

- The chucks segment is expected to hold the largest share of the global CNC work holding product market during the forecast period.

Based on product type, the global CNC work holding product market is categorized as chucks, clamps, vices, fixtures, and others. Among these, the chucks segment is expected to hold the largest share of the global CNC work holding Product market during the forecast period. Their versatility, precision, and compatibility with automated systems make them a staple in automotive, aerospace, and medical devices applications. Hydraulic and power chucks are especially in high demand for high-precision applications where stability and efficiency are vital. With further automation in full swing, the use of chucks in advanced manufacturing processes will further cement them as market leaders.

- The medical devices segment is expected to grow at the fastest CAGR during the forecast period.

Based on the application, the global CNC work holding product market is categorized as the automotive industry, aerospace industry, medical devices, industrial equipment and others. Among these, the medical devices segment is expected to grow at the fastest CAGR during the forecast period. This growth is driven by the increasing demand for precision components used in implants, surgical instruments, and diagnostic equipment. As the healthcare industry advances, the need for high-accuracy, custom work holding solutions for complex medical device manufacturing is increasing, boosting market growth in this sector.

Regional Segment Analysis of the Global CNC Work holding Product Market

- North America (U.S., Canada, Mexico)

- Europe (Germany, France, U.K., Italy, Spain, Rest of Europe)

- Asia Pacific (China, Japan, India, Rest of APAC)

- South America (Brazil and the Rest of South America)

- The Middle East and Africa (UAE, South Africa, Rest of MEA)

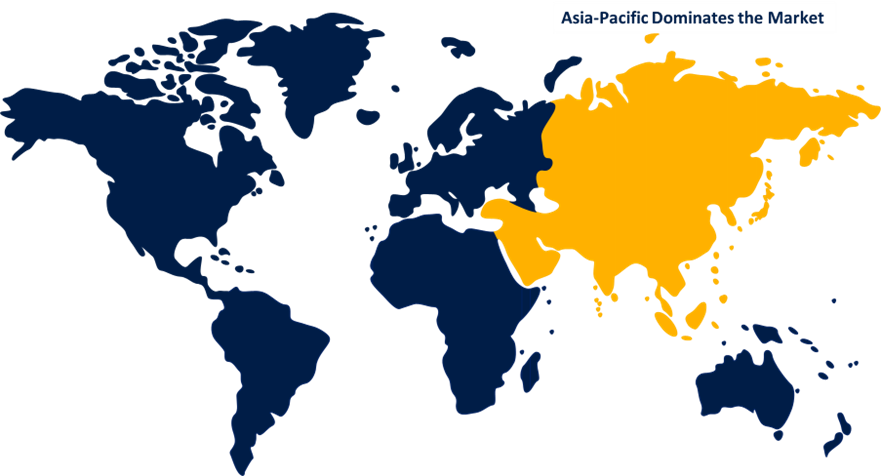

Asia Pacific is projected to hold the largest share of the global CNC work holding product market over the forecast period.

Get more details on this report -

Asia Pacific is projected to hold the largest share of the global CNC work holding product market over the forecast period. This is due to the strong manufacturing base in this region, especially in countries like China, Japan, India, and South Korea, which are major producers of automobiles, aerospace, and electronics. An increase in the adoption of automation, Industry 4.0 technologies, and government initiatives towards advanced manufacturing also increases the demand for high-precision CNC work holding solutions. Cost advantages also favour market growth in this region. For instance, in August 2024, Okuma America Corp. announced the Okuma Robot Leader, or ORL, series of automation. It includes three proprietary products designed to load and unload workpieces from Okuma machines to increase productivity and operator efficiency, said the company.

North America is expected to grow at the fastest CAGR growth of the global CNC work holding product market during the forecast period. Strong demand from the automotive, aerospace, medical devices, and industrial equipment sectors is further fueling this growth. Widespread adoption of automation, smart work holding, and Industry 4.0 technologies plus heavy investments in infrastructure and R&D are accelerating the need for advanced, high-precision work holding solutions, making North America the most important market in this forecast period.

Competitive Analysis:

The report offers the appropriate analysis of the key organizations/companies involved within the global CNC work holding product market along with a comparative evaluation primarily based on their product offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborative analysis focusing on the current news and developments of the companies, which includes product development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

List of Key Companies

- Gerardi SPA

- EROWA

- CPWS

- 5th Axis

- TE-CO Manufacturing

- Elijah Tooling

- DMT Workholding

- Jergens

- Positrol

- LMC Workholding

- Norgren (IMI)

- Forkardt

- Others

Key Target Audience

- Market Players

- Investors

- End-users

- Government Authorities

- Consulting And Research Firm

- Venture capitalists

- Value-Added Resellers (VARs)

Key Market Developments

- In March 2024, FANUC America Corporation released its new combined PLC/CNC motion controller Power Motion i-MODEL A Plus, PMi-A Plus. Users worldwide trust FANUC's control and servo technology, reliability, and support for CNC machine tools, but PMi-A Plus unlocks the ability to use FANUC controls for general motion control equipment.

Market Segment

This study forecasts revenue at global, regional, and country levels from 2020 to 2033. Spherical Insights has segmented the global CNC work holding product market based on the below-mentioned segments:

Global CNC Work holding Product Market, By Product Type

- Chucks

- Clamps

- Vices

- Fixtures

- Others

Global CNC Work holding Product Market, By Application

- Automotive Industry

- Aerospace Industry

- Medical Devices

- Industrial Equipment

- Others

Global CNC Work holding Product Market, By Regional

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

Frequently Asked Questions (FAQ)

-

1. Which region is expected to hold the highest share of the global CNC work holding product market?Asia Pacific is projected to hold the largest share of the global CNC work holding product market over the forecast period.

-

2. Who are the top key players in the global CNC work holding product market?Jergens, Positrol, LMC Workholding, Norgren (IMI), Forkardt, Gerardi SPA, EROWA, CPWS, 5th Axis, TE-CO Manufacturing, Elijah Tooling, DMT Workholding, Kurt Workholding, and Others.

Need help to buy this report?