Global Dry Ramming Mass Market Size, Share, and COVID-19 Impact Analysis, By Type (Alumina Ramming Mass, Silica Ramming Mass, Magnesia Based Ramming Mass and Others), By Application (Foundries, Blast Furnace, Electric Arc Furnace, Steel, Non steel and Others), By Function (Lining, Repairing, Patching and Others), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2023 - 2033

Industry: Chemicals & MaterialsGlobal Dry Ramming Mass Market Insights Forecasts to 2033

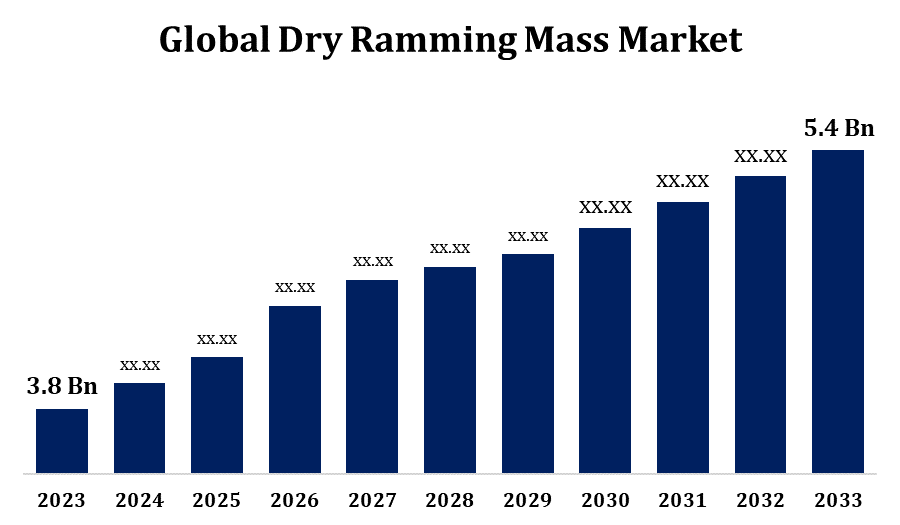

- The Dry Ramming Mass Market was valued at USD 3.8 Billion in 2023.

- The Market Size is Growing at a CAGR of 3.58% from 2023 to 2033.

- The Worldwide Dry Ramming Mass Market Size is Expected to reach USD 5.4 Billion by 2033.

- Asia Pacific is Expected to Grow the fastest during the forecast period.

Get more details on this report -

The Global Dry Ramming Mass Market Size is Expected to reach USD 5.4 Billion by 2033, at a CAGR of 3.58% during the forecast period 2023 to 2033.

The dry ramming mass market is witnessing significant growth, driven by its increasing application in steel and non-ferrous metal industries. Composed of refractory materials, dry ramming mass is essential for linings in induction furnaces, providing superior thermal stability and resistance to mechanical wear. The market is influenced by the rising demand for high-efficiency furnaces and the need for energy-efficient solutions in metal production. Key factors propelling this market include rapid industrialization, the expansion of the automotive and construction sectors, and stringent regulations promoting eco-friendly materials. Geographically, Asia-Pacific dominates the market due to robust industrial activities, followed by North America and Europe. Innovations in formulations and increased investments in research and development further enhance market growth prospects.

Dry Ramming Mass Market Value Chain Analysis

The dry ramming mass market value chain encompasses several key stages, starting with raw material sourcing, where refractory materials like alumina and silica are procured. These materials are then processed and blended to create the dry ramming mass formulation, which is tailored for specific applications. Manufacturing involves mixing, granulating, and packaging the final product, ensuring quality control at each stage. Distribution follows, with logistics handling the transportation of products to various end-users, including steel and non-ferrous metal producers. End-users employ dry ramming mass in induction furnaces for optimal performance. Feedback from users informs manufacturers about performance improvements and innovation opportunities. Overall, collaboration among suppliers, manufacturers, and end-users is vital for enhancing product quality and meeting market demands effectively.

Dry Ramming Mass Market Opportunity Analysis

The dry ramming mass market presents significant opportunities driven by increasing demand for efficient and durable refractory materials in various industries. The rise in steel production, particularly in emerging economies, creates a robust market for dry ramming mass as it is essential for induction furnaces. Additionally, the trend towards energy-efficient and eco-friendly manufacturing processes aligns with the benefits of dry ramming mass, which enhances thermal efficiency and reduces energy consumption. Innovations in product formulations can address specific performance challenges, further expanding market potential. Moreover, the growing adoption of advanced technologies in metal production and the expansion of the automotive and construction sectors offer lucrative opportunities. Strategic partnerships and collaborations within the supply chain can also enhance market penetration and foster sustainable growth.

Global Dry Ramming Mass Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2023 |

| Market Size in 2023 : | USD 3.8 Billion |

| Forecast Period: | 2023-2033 |

| Forecast Period CAGR 2023-2033 : | 3.58% |

| 2033 Value Projection: | USD 5.4 Billion |

| Historical Data for: | 2019-2022 |

| No. of Pages: | 221 |

| Tables, Charts & Figures: | 110 |

| Segments covered: | By Type, By Function, By Region |

| Companies covered:: | Vesuvius, Calderys, HarbisonWalker International, Magnesita Refratários S.A., Saint-Gobain, RHI Magnesita, Resco Products, Minteq International Inc., Imerys Refractory Minerals, Morgan Advanced Materials, and Others |

| Pitfalls & Challenges: | Covid-19 Empact, Challenges, Growth, Analysis. |

Get more details on this report -

Market Dynamics

Dry Ramming Mass Market Dynamics

The expanding steel industry is fueling market growth

The expanding steel industry is significantly driving growth in the dry ramming mass market. As steel production continues to rise globally, the demand for high-performance refractory materials used in induction furnaces is increasing. Dry ramming mass plays a crucial role in enhancing the efficiency and longevity of these furnaces, providing superior thermal resistance and minimizing wear. The shift towards more efficient manufacturing processes and the need for energy conservation further amplify this demand, as dry ramming mass contributes to improved thermal management and reduced energy costs. Additionally, the growth of emerging economies, which are ramping up their steel production capacities, presents further opportunities for market expansion. Overall, the synergy between the steel industry's growth and the dry ramming mass market creates a robust outlook for future development.

Restraints & Challenges

The dry ramming mass market faces several challenges that could impact its growth trajectory. One significant issue is the volatility of raw material prices, which can affect production costs and profitability for manufacturers. Additionally, the increasing focus on sustainability and the need for eco-friendly materials pose a challenge, as companies must innovate to develop greener alternatives while maintaining performance standards. Competition from alternative refractory materials may also hinder market expansion, as advancements in technology could lead to the adoption of substitute products. Furthermore, the complexity of manufacturing processes and the requirement for skilled labor can create operational difficulties. Finally, fluctuations in demand from the steel and non-ferrous metal industries, influenced by global economic conditions, can lead to uncertainty in market dynamics.

Regional Forecasts

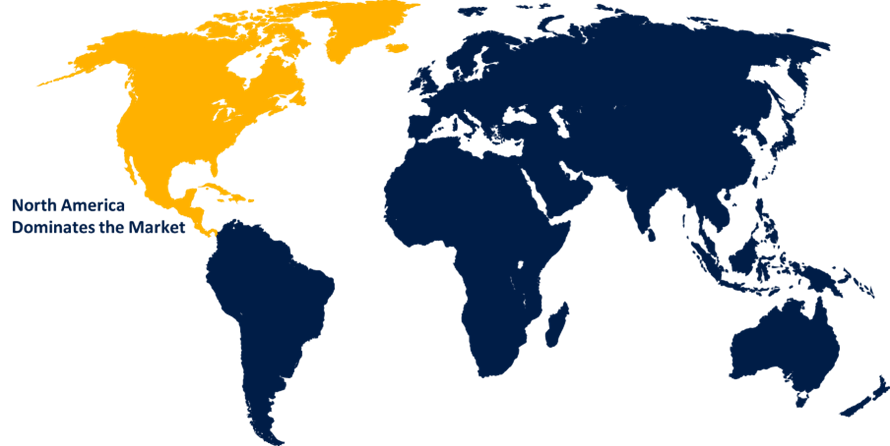

North America Market Statistics

Get more details on this report -

North America is anticipated to dominate the Dry Ramming Mass Market from 2023 to 2033. Major players in the region are focusing on technological advancements and innovative formulations to enhance product quality and performance. The presence of well-established steel manufacturers and foundries, particularly in the United States, supports the demand for dry ramming mass, which is critical for efficient induction furnace operations. Furthermore, strict environmental regulations are encouraging the adoption of eco-friendly refractory solutions, providing new opportunities for market expansion. Challenges such as fluctuating raw material prices and competition from alternative refractory products remain, but overall, the North American market is poised for growth, supported by industrial advancements and increasing investments in infrastructure.

Asia Pacific Market Statistics

Asia Pacific is witnessing the fastest market growth between 2023 to 2033. Emerging nations are leading steel producers, significantly increasing the demand for refractory materials used in induction furnaces. The region's focus on enhancing production efficiency and energy conservation further propels the adoption of dry ramming mass, known for its excellent thermal stability and durability. Additionally, the growing automotive and construction industries contribute to the rising need for non-ferrous metal applications. Despite challenges such as fluctuating raw material costs and environmental regulations, the Asia-Pacific market is expected to witness substantial growth, bolstered by ongoing infrastructure projects and investments in advanced manufacturing technologies.

Segmentation Analysis

Insights by Type

The Alumina Ramming Mass segment accounted for the largest market share over the forecast period 2023 to 2033. Alumina-based formulations offer excellent thermal resistance, mechanical strength, and corrosion protection, making them ideal for use in induction furnaces and other high-temperature applications. As industries strive for improved efficiency and reduced operational costs, the demand for alumina ramming mass is increasing, especially in steel and non-ferrous metal production. Additionally, the trend towards energy-efficient manufacturing processes is driving the adoption of alumina ramming mass, which enhances thermal management and reduces energy consumption. The ongoing technological advancements in alumina formulations further expand their application scope, contributing to the segment's growth and positioning it as a preferred choice among manufacturers in the dry ramming mass market.

Insights by Application

The foundries segment accounted for the largest market share over the forecast period 2023 to 2033. As foundries seek to enhance production efficiency and reduce downtime, the adoption of high-quality dry ramming mass becomes essential for optimal furnace performance. This material is crucial for the lining of induction furnaces, offering superior thermal stability and wear resistance, which are vital for metal melting processes. The expansion of automotive, aerospace, and construction sectors is further fueling the need for casting solutions, thereby boosting the foundries segment. Additionally, technological advancements and the development of innovative ramming mass formulations tailored for specific applications enhance the segment's attractiveness. Overall, the growth of the foundries segment is poised to contribute significantly to the overall expansion of the dry ramming mass market.

Insights by Function

The lining segment accounted for the largest market share over the forecast period 2023 to 2033. As industries focus on increasing production efficiency and reducing maintenance costs, the demand for high-quality lining materials has surged. Dry ramming mass provides exceptional thermal resistance, mechanical strength, and resistance to chemical attack, making it an ideal choice for furnace linings. The growth of steel and non-ferrous metal industries, along with the expansion of foundries, is driving this segment as manufacturers seek reliable materials that can withstand extreme conditions. Furthermore, ongoing advancements in ramming mass formulations tailored for specific applications are enhancing their performance, thus supporting the growth of the lining segment within the broader dry ramming mass market.

Recent Market Developments

- On April 2023, AM/NS India received approval from India's regulatory body, the NCLT, to acquire Indian Steel Corporation. This acquisition is intended to enhance its downstream capabilities and expand its product portfolio.

Competitive Landscape

Major players in the market

- Vesuvius

- Calderys

- HarbisonWalker International

- Magnesita Refratários S.A.

- Saint-Gobain

- RHI Magnesita

- Resco Products

- Minteq International Inc.

- Imerys Refractory Minerals

- Morgan Advanced Materials

- Others

Market Segmentation

This study forecasts revenue at global, regional, and country levels from 2023 to 2033.

Dry Ramming Mass Market, Type Analysis

- Alumina Ramming Mass

- Silica Ramming Mass

- Magnesia Based Ramming Mass

- Others

Dry Ramming Mass Market, Application Analysis

- Foundries

- Blast Furnace

- Electric Arc Furnace

- Steel

- Non steel

- Others

Dry Ramming Mass Market, Function Analysis

- Lining

- Repairing

- Patching

- Others

Dry Ramming Mass Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

Frequently Asked Questions (FAQ)

-

1. What is the market size of the Dry Ramming Mass Market?The global Dry Ramming Mass Market is expected to grow from USD 3.8 billion in 2023 to USD 5.4 billion by 2033, at a CAGR of 3.58% during the forecast period 2023-2033.

-

2. Who are the key market players of the Dry Ramming Mass Market?Some of the key market players of the market are Vesuvius, Calderys, HarbisonWalker International, Magnesita Refratários S.A., Saint-Gobain, RHI Magnesita, Resco Products, Minteq International Inc., Imerys Refractory Minerals, Morgan Advanced Materials.

-

3. Which segment holds the largest market share?The automotive segment holds the largest market share and is going to continue its dominance.

-

4. Which region dominates the Dry Ramming Mass Market?North America dominates the Dry Ramming Mass Market and has the highest market share.

Need help to buy this report?