Global Electric Vehicle Adhesives Market Size, Share, and COVID-19 Impact, By Resin Type (Epoxy, Acrylic, Silicone, Polyurethane), By Form Type (Film & Tape, Liquid), By Vehicle Type (Battery Electric Vehicle, Plug-In Hybrid Electric Vehicle), By Application (Pack & Module Bonding, Battery Cell Encapsulation, Thermal Interface Bonding), By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2022 - 2032.

Industry: Chemicals & MaterialsGlobal Electric Vehicle Adhesives Market Insights Forecasts to 2032

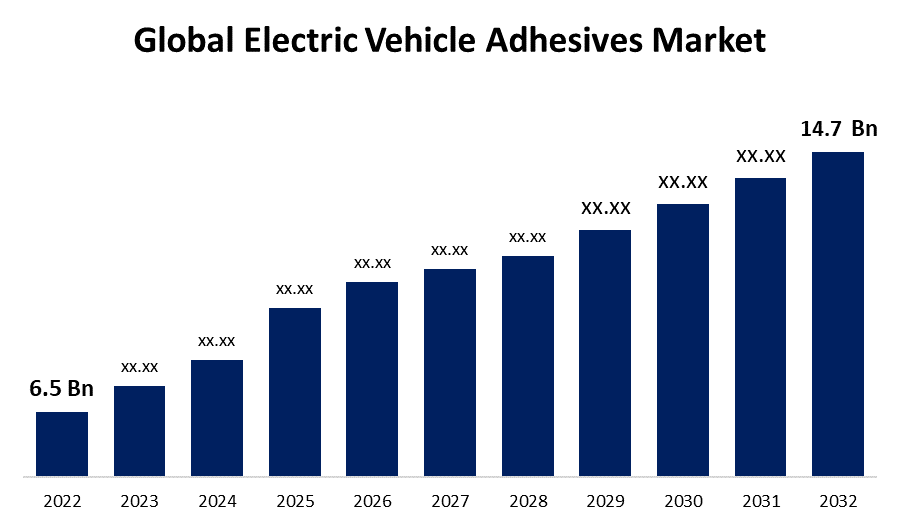

- The Electric Vehicle Adhesives Market Size was valued at USD 6.5 Billion in 2022.

- The market Size is growing at a CAGR of 48.1% from 2022 to 2032.

- The worldwide Electric Vehicle Adhesives Market Size is expected to reach USD 14.7 Billion by 2032.

- North America is expected to grow the fastest during the forecast period.

Get more details on this report -

The Global Electric Vehicle Adhesives Market Size is expected to reach USD 14.7 Billion by 2032, at a CAGR of 48.1% during the forecast period 2022 to 2032.

Electric vehicle adhesives are essential to the design, construction, and assembly of EVs. Specialised adhesives are required to assure the structural integrity, safety, and performance of EVs because they differ from conventional internal combustion engine vehicles in terms of their characteristics and requirements. These adhesives are made to offer a solid bind between the various metals, composites, and polymers used in the manufacturing of electric vehicles. They are utilised to join structural elements and parts such the battery pack, chassis, and body panels. Structural adhesives reduce weight and use of conventional welding techniques while enhancing the vehicle's overall stiffness and strength.

Impact of COVID-19 On Global Electric Vehicle Adhesives Market.

Global supply chains were interrupted by the pandemic, which had an impact on the supply of the raw ingredients and components needed to make the adhesives for electric vehicles. Lockdowns and travel restrictions were implemented by many nations, which caused factory closures and logistical difficulties. As a result, some glue producers had trouble locating the raw ingredients they needed and marketing their goods. For the duration of the shutdown, many EV manufacturers had to temporarily halt operations in order to protect their employees. The demand for adhesives for electric vehicles was hampered by the manufacturing slowdown and reduction in production capacity. In order to satisfy the urgent needs of the pandemic, certain adhesive producers, especially those supplying numerous industries, diverted their production capacities towards producing medical equipment, personal protective equipment (PPE), and sanitization goods. This change in emphasis might have had an impact on the supply and accessibility of adhesives for electric vehicles.

Electric Vehicle Adhesives Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2022 |

| Market Size in 2022: | USD 6.5 Billion |

| Forecast Period: | 2022-2032 |

| Forecast Period CAGR 2022-2032 : | 48.1% |

| 2032 Value Projection: | 14.7 Billion |

| Historical Data for: | 2018-2021 |

| No. of Pages: | 200 |

| Tables, Charts & Figures: | 240 |

| Segments covered: | COVID-19 Impact, By Resin Type, By Form Type, By Vehicle Type, By Application, By Region |

| Companies covered:: | Henkel, Wacker Chemie AG, Sika AG, Permabond. H.B. Fuller, PPG Industries, 3M, Parker Hannifin Corp, Lord Corporation, Jowat SE, Ashland, Bostik. |

| Pitfalls & Challenges: | COVID-19 Empact,Challenges, Future, Growth, & Analysis |

Get more details on this report -

Key Market Drivers

Due to rising environmental awareness, government incentives, and improvements in EV technology, the global market for electric vehicles was expanding quickly. The demand for specialised adhesives used in their manufacturing and assembly expanded along with the demand for electric vehicles. The development of adhesives with improved qualities, such as greater temperature resistance, more sturdiness, and improved electrical conductivity, is the result of ongoing research and development activities in the adhesive business. These developments specifically addressed the requirements of electric vehicles. Numerous adhesive producers and suppliers have made investments in R&D and capacity expansion in response to the market's potential for growth in the electric car sector. Adhesives are employed to build battery modules, glue battery cells together, and guarantee proper thermal management in the electric car batteries. Specialised adhesives made specifically for the particular needs of battery systems were required by the expansion of the EV market.

Key Market Challenges.

Extreme cold to high heat produced during operation—electric cars operate in a wide range of temperatures. Under these various circumstances, adhesives used in EVs must preserve their characteristics and functionality. The durability and safety of the vehicle depend on ensuring long-term resistance to external conditions such humidity, wetness, and chemical exposure. Weight reduction is a priority for electric vehicles in order to improve performance and expand range. Adhesives must therefore successfully attach various lightweight materials, including composites, aluminium, and high-strength steel. It can be difficult to guarantee these materials' harmony and long-term adherence. Compared to conventional adhesives used in internal combustion engine vehicles, electric vehicle adhesives with specialised characteristics and capabilities may cost more. To achieve widespread use of electric car adhesives, performance and cost-effectiveness must be balanced.

Market Segmentation

Resin Type Insights

Polyurethane segment is dominating the market over the forecast period

On the basis of resin type, the global electric vehicle adhesives market is segmented into epoxy, acrylic, silicone, polyurethane, and others. Among these, polyurethane segment is dominating the market with the largest market share over the forecast period. Manufacturers are spending money on R&D to improve the formulas of polyurethane adhesives designed specifically for use in electric car applications. As a result, better adhesives have been developed to meet the changing demands of the electric car sector. In comparison to some conventional joining techniques like welding or mechanical fastening, polyurethane adhesives are lightweight. The usage of lightweight adhesives is becoming more and more appealing as electric vehicles concentrate on reducing weight to improve energy efficiency and range.

Form Type Insights

Liquid segment accounted the largest market share over the forecast period

Based on the form type, the global electric vehicle adhesives market is segmented into film & tape, liquid, and others. Among these, the liquid segment accounted the largest market share over the forecast period. Liquid adhesives may be applied easily and precisely to a variety of surfaces and components in electric vehicles utilising a variety of processes, including brushing, spraying, and dispensing. Different curing methods, such as moisture curing or heat curing, can be incorporated into the formulation of liquid adhesives, enabling a range of curing speeds to accommodate diverse assembly procedures and production demands. The ability to develop liquid adhesives to meet safety requirements and have fire-resistant qualities is essential for use with electric car battery applications.

Vehicle Type Insights

Plug-In Hybrid Electric Vehicle segment is dominating the market over the forecast period

On the basis of vehicle type, the global electric vehicle adhesives market is segmented into battery Electric Vehicles and plug-in hybrid Electric Vehicles. Among these, plug-in hybrid electric vehicle segment is dominating the market over the forecast period. For the battery pack, which contains both traditional lead-acid batteries and cutting-edge lithium-ion batteries, PHEVs need strong adhesive solutions. Adhesives are essential for maintaining the battery pack's stability and safety under a variety of operating circumstances. Due to their dual powertrain configuration, PHEVs raise special cost issues. The producers of PHEVs seek adhesives that balance performance and cost-effectiveness.

Application Insights

Pack and module bonding segment holds the highest market share

Based on the application, the global electric vehicle adhesives market is segmented into pack & module bonding, battery cell encapsulation, thermal interface bonding, and others. Among these, pack and module segment holds the highest market share over the forecast period. High-energy-density battery cells and modules have been developed as a result of substantial breakthroughs in battery technology for electric vehicles. These cutting-edge battery components are bonded and sealed using adhesives, guaranteeing their reliable performance and security. In line with the automobile industry's push for the principles of the circular economy, adhesive solutions that make it simpler to recycle battery parts and materials are becoming more important.

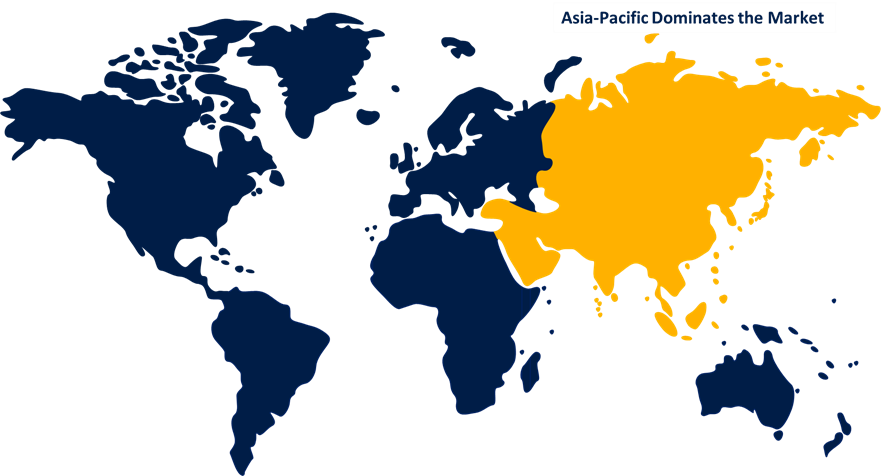

Regional Insights

Asia Pacific is dominating the market over the forecast period

Get more details on this report -

Asia Pacific region is dominating the market with the largest market share over the forecast period. With nations like China, South Korea, and Japan being prominent players in the global battery sector, the Asia Pacific area is a crucial hub for the production of batteries. Specialised adhesives are necessary for battery assembly, which raises the demand for electric car adhesives in the area. A large number of top automakers are making investments in the research and production of electric vehicles in the Asia Pacific area. The market for electric vehicle adhesives has expanded as a result of this boom in electric car production.

North America is witnessing the fastest market growth over the forecast period. The development of electric vehicle technology is a constant focus of research and development by North American automakers and technology firms. The demand for sophisticated adhesives to support these advancements grows as battery technologies and EV components progress. The convenience and viability of owning an electric car have improved due to the growth of the infrastructure for charging them in North America, which has raised customer interest in and demand for them.

Recent Market Developments

- In November 2022, At the 5th China International Import Expo (CIIE 2022) Dow debuted a new line of VORATRONTM MA 8200S high-bonding adhesives.

List of Key Companies

- Henkel

- Wacker Chemie AG

- Sika AG

- Permabond. H.B. Fuller

- PPG Industries

- 3M

- Parker Hannifin Corp

- Lord Corporation

- Jowat SE

- Ashland

- Bostik

Market Segment

This study forecasts revenue at global, regional, and country levels from 2019 to 2032. Spherical Insights has segmented the global Electric Vehicle Adhesives Market based on the below-mentioned segments:

Electric Vehicle Adhesives Market, Resin Type Analysis

- Epoxy

- Acrylic

- Silicone

- Polyurethane

- Others

Electric Vehicle Adhesives Market, Form Type Analysis

- Film & tape

- Liquid

- Others

Electric Vehicle Adhesives Market, Vehicle Type Analysis

- Battery Electric Vehicles

- Plug-in hybrid Electric Vehicles

Electric Vehicle Adhesives Market, Application Analysis

- Pack & module bonding

- Battery cell encapsulation

- Thermal interface bonding

- Others

Electric Vehicle Adhesives Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of Middle East & Africa

Frequently Asked Questions (FAQ)

-

1. What is the market size of Electric Vehicle Adhesives Market?The global Electric Vehicle Adhesives Market is expected to grow from USD 6.5 Billion in 2022 to USD 14.7 Billion by 2032, at a CAGR of 48.1% during the forecast period 2022-2032.

-

2. Who are the key market players of Electric Vehicle Adhesives Market?Some of the key market players of Henkel, Wacker Chemie AG, Sika AG, Permabond. H.B. Fuller, PPG Industries, 3M, Parker Hannifin Corp, Lord Corporation, Jowat SE, Ashland, and Bostik.

-

3. Which segment hold the largest market share?Polyurethane holds the largest market share is going to continue its dominance.

-

4. Which region is dominating the Electric Vehicle Adhesives Market?Asia Pacific is dominating the Electric Vehicle Adhesives Market with the highest market share.

Need help to buy this report?