Global Electrical Appliance Coatings Market Size, Share, and COVID-19 Impact Analysis, By Type (Epoxies, Acrylics, Alkyds, Polyurethanes, Polycarbonates, Others), By Application (Refrigeration Appliances, Laundry Appliances, Dishwashers, Air Treatment Appliances, Cooking Appliances, Personal Care Appliances, Entertainment Appliances), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2023 - 2033.

Industry: Advanced MaterialsGlobal Electrical Appliance Coatings Market Insights Forecasts to 2033

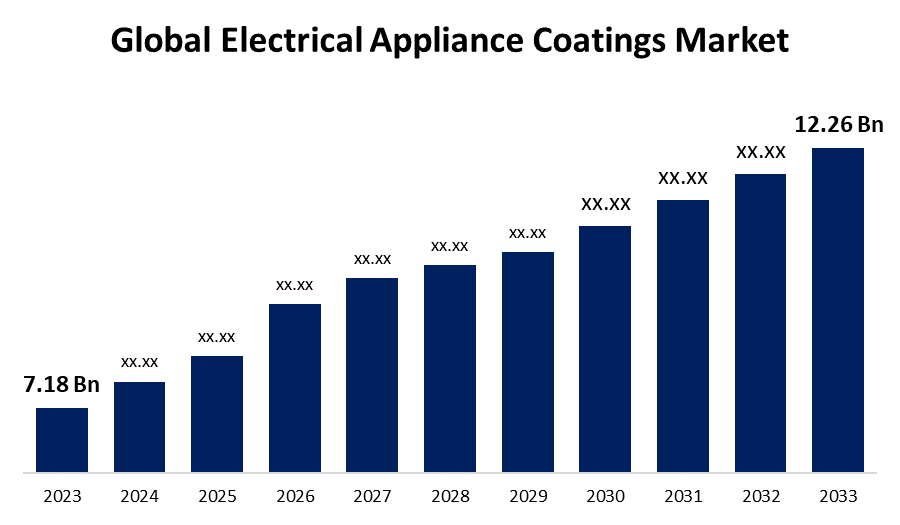

- The Global Electrical Appliance Coatings Market Size was Valued at USD 7.18 Billion in 2023

- The Market Size is Growing at a CAGR of 5.50% from 2023 to 2033

- The Worldwide Electrical Appliance Coatings Market Size is Expected to Reach USD 12.26 Billion by 2033

- North America is Expected to Grow the fastest during the forecast period.

Get more details on this report -

The Global Electrical Appliance Coatings Market Size is Anticipated to Exceed USD 12.26 Billion by 2033, Growing at a CAGR of 5.50% from 2023 to 2033.

Market Overview

Electrical appliance coatings are protective layers applied to electrical devices to enhance their performance, durability, and safety. Electrical appliance coatings enhance performance and durability by providing insulation, corrosion, and heat resistance, improving electrical conductivity, enhancing aesthetic appeal, and offering anti-microbial properties. They also protect against wear and environmental factors. Electrical appliance coatings are propelled due to safety regulations, durability, performance, aesthetic appeal, technological advancements, environmental concerns, and market competition.

For Instance, In November 2023, Nordson Electronics Solutions introduced the ASYMTEK Select Coat SL-1040 conformal coating system for high-volume printed circuit assembly production. This advanced solution enhances automation, control, precision, and preventive maintenance, improving yield and uptime.

Report Coverage

This research report categorizes the market for electrical appliance coatings based on various segments and regions forecasts revenue growth and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the electrical appliance coatings market. Recent market developments and competitive strategies such as expansion, product launch, development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the electrical appliance coatings market.

Global Electrical Appliance Coatings Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2023 |

| Market Size in 2023: | USD 7.18 Billion |

| Forecast Period: | 2023-2033 |

| Forecast Period CAGR 2023-2033 : | 5.50% |

| 2033 Value Projection: | USD 12.26 Billion |

| Historical Data for: | 2019-2022 |

| No. of Pages: | 255 |

| Tables, Charts & Figures: | 85 |

| Segments covered: | By Type, By Application, By Region |

| Companies covered:: | DSM, Rust-Oleum, Henkel Adhesives Technologies India Private Limited, Altana, Evonik Industries, Nippon Electric Glass Co., Ltd., Erie Powder Coatings, GMMDL, Axalta Coating Systems, LLC., AGC Chemicals Europe, Ltd., CEKO, Inc., Daikin Industries, Ltd., and other key companies. |

| Pitfalls & Challenges: | COVID-19 Empact, Challenge, Future, Growth, & Analysis |

Get more details on this report -

Driving Factors

The growth of the electrical appliance coatings market is driven by several key factors including the rising demand for consumer electronics and technological advancements that promote eco-friendly and high-performance coatings. Durability and protection against environmental factors enhance the longevity of appliances, while aesthetic appeal increasingly influences consumer choices. The growth of smart appliances necessitates advanced coatings that meet evolving functionalities. Furthermore, expanding markets in regions like the Asia Pacific and compliance with stringent regulatory standards further propel the demand for sustainable coating markets.

Restraining Factors

The electrical appliance coatings market is constrained by several restraining factors including high production costs and stringent regulatory compliance related to chemical safety and environmental standards. Intense competition among manufacturers can lead to price wars, impacting profitability and innovation. Furthermore, volatility in raw material prices can disrupt supply chains, while consumer preferences for low-cost products might limit demand for high-quality coatings.

Market Segmentation

The electrical appliance coatings market share is classified into type and application.

- The polyurethanes segment is estimated to hold the highest market revenue share through the projected period.

Based on the type, the electrical appliance coatings market is classified into epoxies, acrylics, alkyds, polyurethanes, polycarbonates, and others. Among these, the polyurethanes segment is estimated to hold the highest market revenue share through the projected period. The dominance of the polyurethane segment is driven by their exceptional properties, such as high durability, flexibility, and resistance to chemicals and moisture, which make them particularly suitable for a wide range of electrical appliances. Their ability to provide a smooth finish and good adhesion further enhances polyurethane segment appeal in the electrical appliance coating market

- The entertainment appliances segment is anticipated to hold the largest market share through the forecast period.

Based on the application, the electrical appliance coatings market is divided into refrigeration appliances, laundry appliances, dishwashers, air treatment appliances, cooking appliances, personal care appliances, and entertainment appliances. Among these, the entertainment appliances segment is anticipated to hold the largest market share through the forecast period. The segment's prominence is attributed to the increasing demand for high-quality finishes and protective coatings that enhance aesthetics and durability in devices such as televisions, gaming consoles, and audio equipment. As consumers prioritize design and functionality, manufacturers are investing in advanced coatings that offer superior resistance to scratches, chemicals, and UV exposure. Furthermore, the rising trend of smart home technology and connected devices further boosts the demand for coatings in the entertainment sector.

Regional Segment Analysis of the Electrical Appliance Coatings Market

- North America (U.S., Canada, Mexico)

- Europe (Germany, France, U.K., Italy, Spain, Rest of Europe)

- Asia-Pacific (China, Japan, India, Rest of APAC)

- South America (Brazil and the Rest of South America)

- The Middle East and Africa (UAE, South Africa, Rest of MEA)

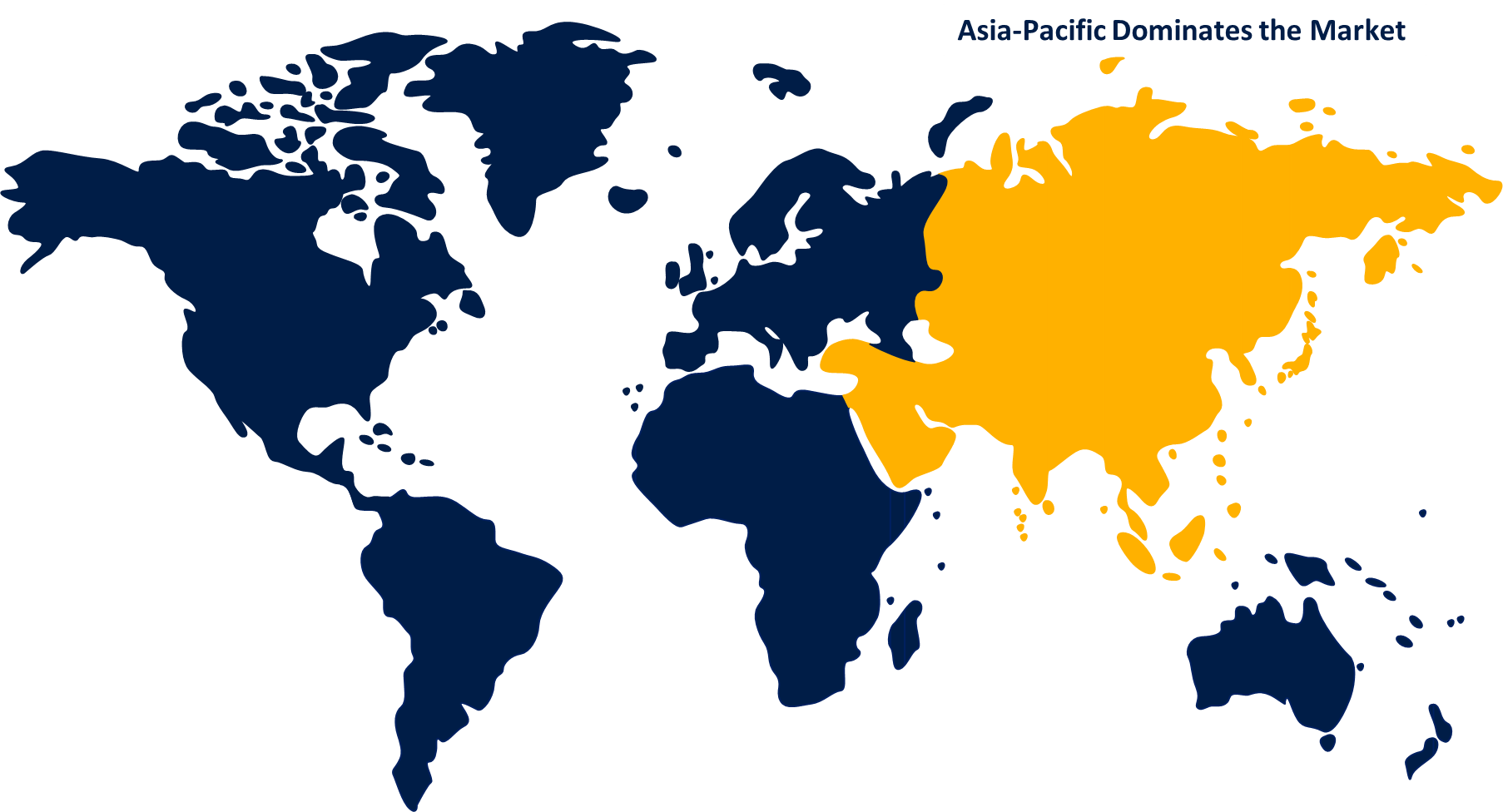

Asia Pacific is anticipated to hold the largest share of the electrical appliance coatings market over the predicted timeframe.

Get more details on this report -

Asia Pacific is anticipated to hold the largest share of the electrical appliance coatings market over the predicted timeframe. The region's dominance can be attributed to several factors including rapid industrialization, increasing consumer electronics production, and rising disposable incomes. Furthermore, the growing demand for high-quality and durable coatings in various applications, such as refrigeration and entertainment appliances, further supports Asia Pacific region leadership in the market.

North America is expected to grow at the fastest CAGR growth of the electrical appliance coatings market during the forecast period. The rapid expansion of the North American region is propelled by several factors including increasing demand for advanced and high-performance coatings, a strong focus on product innovation, and the rising popularity of smart appliances. Furthermore, the region's robust manufacturing base and emphasis on sustainability are fueling the adoption of electrical appliance coatings.

Competitive Analysis:

The report offers the appropriate analysis of the key organizations/companies involved within the electrical appliance coatings market along with a comparative evaluation primarily based on their product offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborative analysis focusing on the current news and developments of the companies, which includes product development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

List of Key Companies

- DSM

- Rust-Oleum

- Henkel Adhesives Technologies India Private Limited

- Altana

- Evonik Industries

- Nippon Electric Glass Co., Ltd.

- Erie Powder Coatings

- GMMDL

- Axalta Coating Systems, LLC.

- AGC Chemicals Europe, Ltd.

- CEKO, Inc.

- Daikin Industries, Ltd.

- Others

Key Target Audience

- Market Players

- Investors

- End-users

- Government Authorities

- Consulting And Research Firm

- Venture capitalists

- Value-Added Resellers (VARs)

Recent Developments

- In September 2024, PPG launched its PPG STEELGUARD 951 epoxy intumescent fire protection coating in the Americas.

- In July 2024, AkzoNobel recently introduced a new line of Resicoat EV powder coatings to preserve the battery system and electrical components of a new generation of electric cars (EVs).

Market Segment

This study forecasts revenue at global, regional, and country levels from 2023 to 2033. Spherical Insights has segmented the electrical appliance coatings market based on the below-mentioned segments:

Global Electrical Appliance Coatings Market, By Type

- Epoxies

- Acrylics

- Alkyds

- Polyurethanes

- Polycarbonates

- Others

Global Electrical Appliance Coatings Market, By Application

- Refrigeration Appliances

- Laundry Appliances

- Dishwashers

- Air Treatment Appliances

- Cooking Appliances

- Personal Care Appliances

- Entertainment Appliances

Global Electrical Appliance Coatings Market, By Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

Frequently Asked Questions (FAQ)

-

1. What is the CAGR of the electrical appliance coatings market over the forecast period?The electrical appliance coatings market is projected to expand at a CAGR of 5.50% during the forecast period.

-

2. What is the market size of the electrical appliance coatings market?The Global Electrical Appliance Coatings Market Size is Expected to Grow from USD 7.18 Billion in 2023 to USD 12.26 Billion by 2033, Growing at a CAGR of 5.50% during the forecast period 2023-2033.

-

3. Which region holds the largest share of the electrical appliance coatings market?Asia Pacific is anticipated to hold the largest share of the electrical appliance coatings market over the predicted timeframe.

Need help to buy this report?