Global Epoxy Tooling Board Market Size, Share, and COVID-19 Impact Analysis, By Type (Polyurethane (PU), Epoxy, and Others), By Density (600-800 kg/m3, 800-1000 kg/m3, and Above 1000 kg/m3), By Application (Aerospace and Defense, Automotive, Wind Energy, and Marine), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2023 - 2033.

Industry: Construction & ManufacturingGlobal Epoxy Tooling Board Market Size Insights Forecasts to 2033

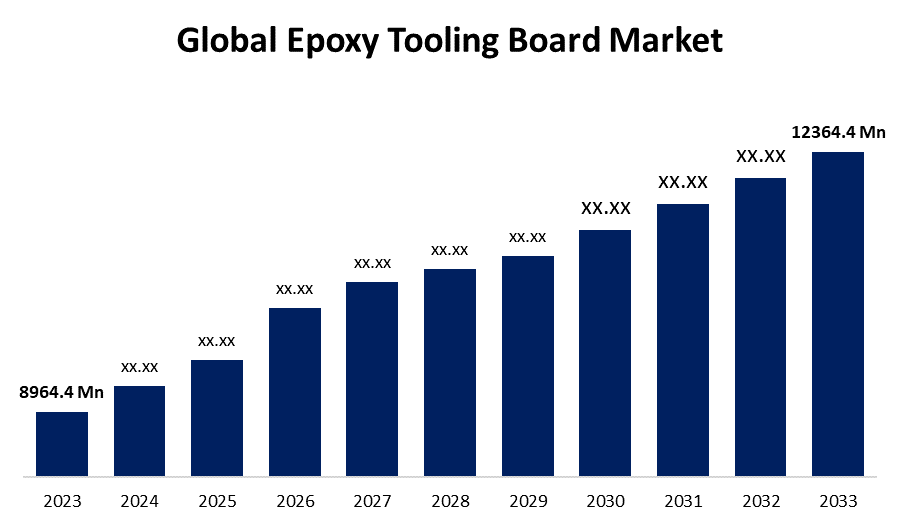

- The Global Epoxy Tooling Board Market Size was Valued at USD 8964.4 Million in 2023

- The Market Size is Growing at a CAGR of 3.27% from 2023 to 2033

- The Worldwide Epoxy Tooling Board Market Size is Expected to Reach USD 12364.4 Million by 2033

- Asia Pacific is Expected to Grow the fastest during the forecast period.

Get more details on this report -

The Global Epoxy Tooling Board Market Size is Anticipated to Exceed USD 12364.4 Million by 2033, Growing at a CAGR of 3.27% from 2023 to 2033.

Market Overview

A specialty material called epoxy tooling board is frequently used in manufacturing processes to create molds, prototypes, and patterns. The fundamental ingredient of epoxy resins is phenol. In the tooling process, this technique is utilized in several sectors to create fixtures, molds, castings, master molds, and more. Polyurethane, epoxy resins, and other materials can be used to make these boards. Laminating and casting are the two fundamental processes that can be used to produce them. Excellent surface finish, heat resistance, thermic resistance, low thermic expansion, ease of polishing, and strong compression resistance are the advantages that these product have to offer. Epoxy tooling boards are frequently used in the aerospace, automotive, and marine industries. They are essential parts of the manufacturing process for prototypes and molds for various uses. The epoxy tooling boards market is still expanding as producers search for cutting-edge materials that make molding and prototyping easier. This tooling board's exceptional qualities are essential for improving accuracy and efficiency in various industrial domains. Due to the increasing usage of epoxy resins in producing wind turbine blades, the epoxy tooling boards market is increasing.

Report Coverage

This research report categorizes the market for the global epoxy tooling board market based on various segments and regions forecasts revenue growth and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the global epoxy tooling board market. Recent market developments and competitive strategies such as expansion, product launch, and development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the global epoxy tooling board market.

Global Epoxy Tooling Board Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2023 |

| Market Size in 2023: | USD 8964.4 Million |

| Forecast Period: | 2023 - 2033 |

| Forecast Period CAGR 2023 - 2033 : | 3.27% |

| 2033 Value Projection: | USD 12364.4 Million |

| Historical Data for: | 2019-2022 |

| No. of Pages: | 228 |

| Tables, Charts & Figures: | 110 |

| Segments covered: | By Type, By Density, By Application, By Region |

| Companies covered:: | Huntsman Corporation, Axson Technologies, Trelleborg AB, General Plastics Manufacturing Company, RAMPF Group Inc, Base Group, Alro Plastics, Coastal Enterprises Inc, Demacq Recycling Company., Sikaaxson, BCC Products Inc., Stevik, Guangzhou LiHong Mould Material Co., Ltd, Curbell Plastics Inc., and Others |

| Pitfalls & Challenges: | Covid 19 Impact Challanges, Future, Growth and Analysis |

Get more details on this report -

Driving Factors

The expansion and development of these sectors supported the growth of the epoxy tooling board industry. Compared to more conventional materials like metal and wood, these tooling boards provide several advantages. They are very well machinable, have a low coefficient of thermal expansion, are highly temperature resistant, and exhibit great dimensional stability. These characteristics increase their appeal to producers looking for accurate and long-lasting tooling solutions. Epoxy tooling boards gained popularity among manufacturers as quick prototyping and shorter product development cycles became more and more important. They make it possible for tooling manufacturing to happen more rapidly, which helps businesses launch their products more quickly.

Restraining Factors

The comparison of epoxy tooling boards to other common tooling materials like steel, aluminum, or wood, they are more costly. Their higher cost prevents them from being widely used, especially in smaller-scale initiatives or economically limited sectors. The adoption of epoxy boards may be limited in some areas or businesses due to their limited availability compared to alternative tooling materials.

Market Segmentation

The global epoxy tooling board market share is classified into type, density, and application.

- The polyurethane segment dominates the market with the largest market share through the forecast period.

Based on the type, the global epoxy tooling board market is categorized into polyurethane (PU), epoxy, and others. Among these, the polyurethane segment dominates the market with the largest market share through the forecast period. Polyurethane, well-known for its remarkable machinability, safety in workshop settings, and temperature stability, is widely used in model and prototype applications in a variety of sectors. It is predicted that this extensive use will positively impact product demand. One important area of application is the rapidly developing field of composite manufacturing, where polyurethane is widely used in CNC-machined plugs and molds.

- The 600-800 kg/m3 segment is anticipated to grow at the fastest CAGR growth through the forecast period.

Based on the density, the global epoxy tooling board market is categorized into 600-800 kg/m3, 800-1,000 kg/m3, and above 1,000 kg/m3. Among these, the 600-800 kg/m3 segment is anticipated to grow at the fastest CAGR growth through the forecast period. It is the most appropriate tooling board segment because it can be used at a wide range of temperatures to create master models and patterns in many end-use industries.

- The aerospace and defense segment accounted for the largest revenue share through the forecast period.

Based on the application, the global epoxy tooling board market is categorized into aerospace and defense, automotive, wind energy, and marine. Among these, the aerospace and defense segment accounted for the largest revenue share through the forecast period. One major factor driving expected product demand is the growing requirement for reasonably priced, dimensionally stable, high-temperature resistant tooling boards that can replace more expensive metal and wooden molds. PU and epoxy tooling boards are useful in the automotive industry because they allow for greater design flexibility and inventiveness.

Regional Segment Analysis of the Global Epoxy Tooling Board Market

- North America (U.S., Canada, Mexico)

- Europe (Germany, France, U.K., Italy, Spain, Rest of Europe)

- Asia-Pacific (China, Japan, India, Rest of APAC)

- South America (Brazil and the Rest of South America)

- The Middle East and Africa (UAE, South Africa, Rest of MEA)

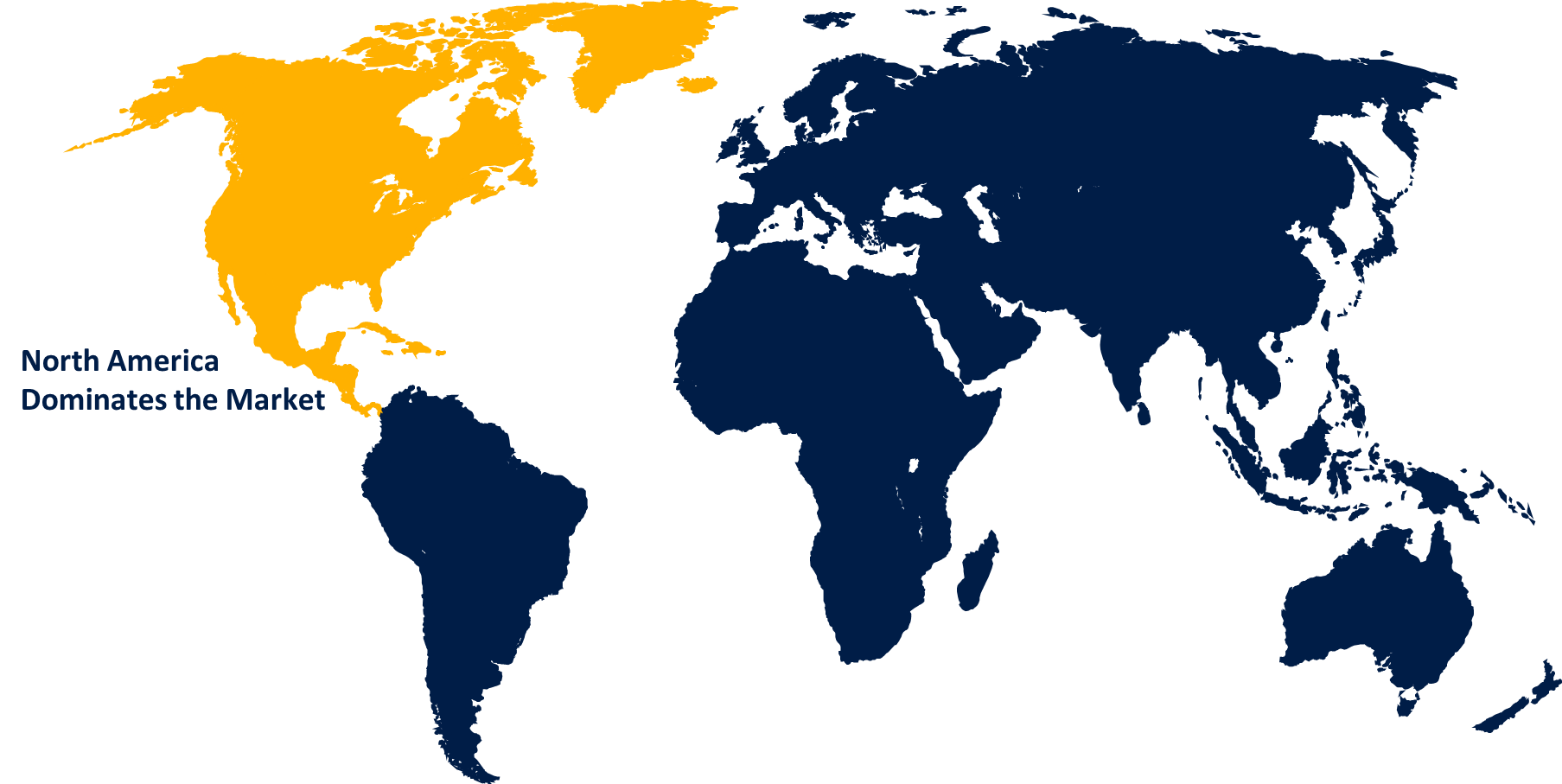

North America is anticipated to hold the largest share of the global epoxy tooling board market over the predicted timeframe.

Get more details on this report -

North America is anticipated to hold the largest share of the global epoxy tooling board market over the predicted timeframe. The rapid prototyping is in high demand because of the region's focus on modern manufacturing technology. In terms of market share for epoxy tooling boards, North America is in the lead. Particularly in the automotive and aerospace sectors, the industrial sectors in the US and Canada are well-established. Because of this region's strong need for high-quality tooling solutions, epoxy boards have found a significant market share in this region.

Asia Pacific is expected to grow at the fastest CAGR growth of the global epoxy tooling board market during the forecast period. Asia Pacific has a booming epoxy tooling board market driven by strong expansion in the automotive and electronics manufacturing industries as well as fast industrialization. The region is a major actor in the global scene because of the dynamic market conditions present.

Competitive Analysis:

The report offers the appropriate analysis of the key organizations/companies involved within the global epoxy tooling board market along with a comparative evaluation primarily based on their product offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborative analysis focusing on the current news and developments of the companies, which includes product development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

List of Key Companies

- Huntsman Corporation

- Axson Technologies

- Trelleborg AB

- General Plastics Manufacturing Company

- RAMPF Group Inc

- Base Group

- Alro Plastics

- Coastal Enterprises Inc

- Demacq Recycling Company.

- Sikaaxson

- BCC Products Inc.

- Stevik

- Guangzhou LiHong Mould Material Co., Ltd

- Curbell Plastics Inc.

- Others

Key Target Audience

- Market Players

- Investors

- End-users

- Government Authorities

- Consulting And Research Firm

- Venture capitalists

- Value-Added Resellers (VARs)

Recent Developments

- In August 2022, Trelleborg AB, a Swedish engineering company, agreed to pay USD 1 billion in cash to buy Minnesota Rubber and Plastics, which is owned by KKR. In 2018, KKR bought Minnesota Rubber and Plastics from Norwest Equity Partners, which was also a private equity firm.

Market Segment

This study forecasts revenue at global, regional, and country levels from 2020 to 2033. Spherical Insights has segmented the global epoxy tooling board market based on the below-mentioned segments:

Global Epoxy Tooling Board Market, By Type

- Polyurethane (PU)

- Epoxy

- Others

Global Epoxy Tooling Board Market, By Density

- 600-800 kg/m3

- 800-1000 kg/m3

- Above 1000 kg/m3

Global Epoxy Tooling Board Market, By Application

- Aerospace

- Automotive

- Wind Energy

- Marine

Global Epoxy Tooling Board Market, By Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

Frequently Asked Questions (FAQ)

-

1. Which are the key companies that are currently operating within the market?Huntsman Corporation, Axson Technologies, Trelleborg AB, General Plastics Manufacturing Company, RAMPF Group Inc., Base Group, Alro Plastics, Coastal Enterprises Inc., Demacq Recycling Company, Sikaaxson, BCC Products Inc., Stevik, Guangzhou LiHong Mould Material Co., Ltd, Curbell Plastics Inc., and Others.

-

2. What is the size of the global epoxy tooling board market?The Global Epoxy Tooling Board Market Size is Expected to Grow from USD 8964.4 Million in 2023 to USD 12364.4 Million by 2033, at a CAGR of 3.27% during the forecast period 2023-2033.

-

3. Which region is holding the largest share of the market?North America is anticipated to hold the largest share of the global epoxy tooling board market over the predicted timeframe.

Need help to buy this report?