Germany Automotive Carbon Fiber Composites Market Size, Share, and COVID-19 Impact Analysis, By Application Type (Power Train Components, Structural Assembly, Exterior, Interior, and Others), By Product Type (Hand Layup, Injection Molding, Vacuum Infusion Processing, Resin Transfer Molding, and Compression Molding), and Germany Automotive Carbon Fiber Composites Market Insights, Industry Trend, Forecasts to 2033.

Industry: Chemicals & MaterialsGermany Automotive Carbon Fiber Composites Market Insights Forecasts to 2033

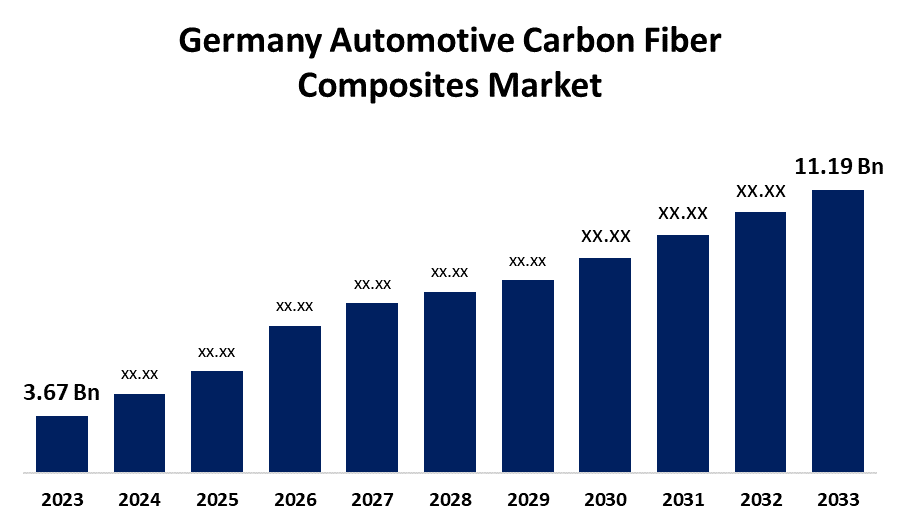

- The Germany Automotive Carbon Fiber Composites Market Size Was Estimated at USD 3.67 Billion in 2023.

- The Market Size is Growing at a CAGR of 11.79% from 2023 to 2033

- The Germany Automotive Carbon Fiber Composites Market Size is Expected to Reach USD 11.19 Billion By 2033

Get more details on this report -

The Germany Automotive Carbon Fiber Composites Market Size is expected to reach USD 11.19 Billion By 2033, Growing at a CAGR of 11.79% from 2023 to 2033.

Market Overview

The industry centered on the manufacture and use of carbon fiber composites in the automobile sector is referred to as the Germany automobile carbon fiber composites Market. These composites, which are strong, lightweight, and corrosion-resistant, are created by embedding carbon fibers into a polymer matrix. The automotive industry is using carbon fiber composites more and more to fulfill rising fuel efficiency criteria because of their greater modulus, strength, impact resistance, and ease of recycling. The Germany automotive carbon fiber composites market is growing due to carbon fiber composites and lightweight materials being in high demand for fuel-efficient automobiles, reducing emissions, and improving performance, particularly in high-performance cars and electric vehicles. In addition, advancements in manufacturing techniques like resin transfer molding and automated fiber insertion are making carbon fiber composites more affordable and scalable for the automobile industry. Furthermore, the German automotive industry is embracing carbon fiber composites to comply with environmental regulations and consumer preferences for sustainable, efficient vehicles, as part of a broader trend toward electromobility.

Report Coverage

This research report categorizes the market for the Germany automotive carbon fiber composites market based on various segments and regions and forecasts revenue growth and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the Germany automotive carbon fiber composites market. Recent market developments and competitive strategies such as expansion, product launch, and development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the Germany automotive carbon fiber composites market.

Germany Automotive Carbon Fiber Composites Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2023 |

| Market Size in 2023: | USD 3.67 Billion |

| Forecast Period: | 2023-2033 |

| Forecast Period CAGR 2023-2033 : | 11.79% |

| 2033 Value Projection: | USD 11.19 Billion |

| Historical Data for: | 2019-2022 |

| No. of Pages: | 240 |

| Tables, Charts & Figures: | 121 |

| Segments covered: | By Application Type, By Product Type and COVID-19 Impact Analysis |

| Companies covered:: | BASF SE, SGL Carbon SE, Solvay Group, Voith GmbH & Co. KGaA, Muhr und Bender KG, Cotesa GmbH, Toray Industries, Inc., BMW AG, Hexcel Corporation, Teijin Limited, and other key vendors. |

| Pitfalls & Challenges: | COVID-19 Empact, Challenge, Future, Growth, & Analysis |

Get more details on this report -

Driving Factors

The Germany automotive carbon fiber composites market is growing due to the growing regulatory pressure to lower CO2 emissions is pushing automakers to find creative ways to lighten their vehicles. By making it possible to produce lighter cars without sacrificing strength or safety, carbon fiber composites provide an appropriate remedy. Additionally, the market dominance of EVs in Germany is anticipated to increase demand for carbon fiber composites due to infrastructural expenditures and government incentives. Furthermore, manufacturing technologies for carbon fiber composites are improving accessibility and cost-effectiveness, lowering production costs, and increasing their competitiveness with more conventional materials like steel and aluminum.

Restraining Factors

The German automotive carbon fiber composites market faces challenges due to high production costs, despite improvements in manufacturing techniques, preventing widespread use in mass-market automobiles. In addition, the development of carbon fiber composites in the automotive industry may be hampered by the scarcity of carbon fibers and the high price of raw ingredients and precursor fibers.

Market Segmentation

The Germany automotive carbon fiber composites market share is classified into application type and product type.

- The exterior segment accounted for the largest market share in 2023 and is expected to grow at a significant CAGR during the forecast period.

Based on the application type, the Germany automotive carbon fiber composites market is divided into power train components, structural assembly, exterior, interior, and others. Among these, the exterior segment accounted for the largest market share in 2023 and is expected to grow at a significant CAGR during the forecast period. This segment is growing because carbon fiber's exceptional strength and low weight make it ideal for body panels, bumpers, hoods, and other external components. Carbon fiber's application in these parts helps lower vehicle weight, improving performance and fuel efficiency, especially for luxury, electric, and high-performance cars. Additionally, the material is preferred by manufacturers who value both functionality and design due to its ability to withstand crashes and enhance vehicle appearance.

- The resin transfer molding segment accounted for the largest market share in 2023 and is expected to grow at a significant CAGR during the forecast period.

Based on the product type, the Germany automotive carbon fiber composites market is divided into hand layup, injection molding, vacuum infusion processing, resin transfer molding, and compression molding. Among these, the resin transfer molding segment accounted for the largest market share in 2023 and is expected to grow at a significant CAGR during the forecast period. This segment is expanding because of its ability to efficiently produce lightweight, highly strengthened components with complex geometries and excellent surface finishes. RTM offers precise control over fiber orientation and resin dispersion, resulting in reliable, high-quality components.

Competitive Analysis:

The report offers the appropriate analysis of the key organizations/companies involved within the Germany automotive carbon fiber composites market along with a comparative evaluation primarily based on their product offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborative analysis focusing on the current news and developments of the companies, which includes product development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

List of Key Companies

- BASF SE

- SGL Carbon SE

- Solvay Group

- Voith GmbH & Co. KGaA

- Muhr und Bender KG

- Cotesa GmbH

- Toray Industries, Inc.

- BMW AG

- Hexcel Corporation

- Teijin Limited

- Others

Key Target Audience

- Market Players

- Investors

- End-users

- Government Authorities

- Consulting And Research Firm

- Venture capitalists

- Value-Added Resellers (VARs)

Recent Development

- In September 2024, Advanced International Multitech (AIM) and KraussMaffei collaborated to create high-pressure resin transfer molded (HP-RTM) carbon fiber wheel rims, which are lightweight and strong enough for use in automobiles.

Market Segment

This study forecasts revenue at the Germany, regional, and country levels from 2020 to 2033. Spherical Insights has segmented the Germany automotive carbon fiber composites market based on the below-mentioned segments

Germany Automotive Carbon Fiber Composites Market, By Application Type

- Power Train Components

- Structural Assembly

- Exterior

- Interior

- Others

Germany Automotive Carbon Fiber Composites Market, By Product Type

- Hand Layup

- Injection Molding

- Vacuum Infusion Processing

- Resin Transfer Molding

- Compression Molding

Need help to buy this report?