Germany Automotive Parts Die Casting Market Size, Share, and COVID-19 Impact Analysis, By Raw Material (Aluminium, Zinc, Magnesium, and Others), By Production (Pressure Die-Casting, Vacuum Die-Casting, Squeeze Die-Casting, and Semi-Solid Die-Casting), and Germany Automotive Parts Die Casting Market Insights, Industry Trend, Forecasts to 2033

Industry: Automotive & TransportationGermany Automotive Parts Die Casting Market Insights Forecasts to 2033

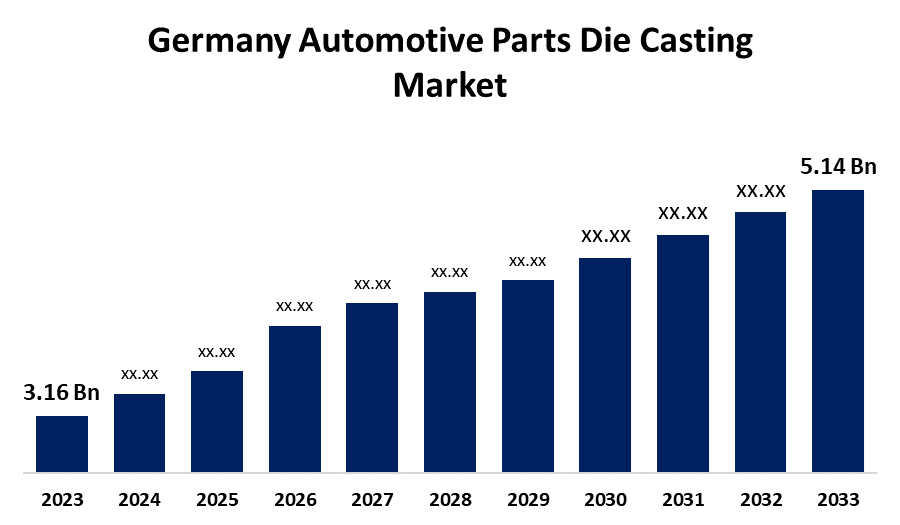

- The Germany Automotive Parts Die Casting Market Size was valued at USD 3.16 Billion in 2023.

- The Market is growing at a CAGR of 4.99% from 2023 to 2033

- The Germany Automotive Parts Die Casting Market Size is Expected to Reach USD 5.14 Billion by 2033

Get more details on this report -

The Germany Automotive Parts Die Casting Market is Anticipated to Exceed USD 5.14 Billion by 2033, growing at a CAGR of 4.99% from 2023 to 2033.

Market Overview

Die casting involves injecting molten metal into a mold cavity to produce automotive parts. The liquid metal is typically a non-ferrous mixture like aluminum or zinc, selected for its beneficial qualities such as being lightweight, strong, and having good dimensional precision. A pattern is used to form the mold cavity, into which the molten metal is injected at high pressure. After the metal has hardened, the mold is opened, and the cast object is taken out, and prepared for additional treatment or putting together. The use of die casting guarantees the manufacture of environmentally friendly and sustainable vehicle components. Die casting permits the manufacture of intricate parts with tight tolerances needed in the automotive industry. The growing need for vehicles that are both light and save fuel. Die casting enables the manufacture of parts that are lighter than those created using conventional techniques, leading to decreased vehicle weight and enhanced fuel efficiency. Improvements in die-casting technology, like the creation of new alloys and enhanced casting methods, are improving the functionality and uses of die-cast components. Another significant factor is the increasing focus on the safety and performance of vehicles. Die casting is capable of producing durable components that comply with strict safety and performance requirements. The capability to create detailed and accurate parts also facilitates advancements in car design and performance, playing a role in the overall progression of the automotive sector.

Report Coverage

This research report categorizes the market for the Germany automotive parts die-casting market based on various segments and regions forecasts revenue growth and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the Germany automotive parts die-casting market. Recent market developments and competitive strategies such as expansion, product launch, and development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the Germany automotive parts die-casting market.

Germany Automotive Parts Die Casting Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2023 |

| Market Size in 2023: | USD 3.16 Billion |

| Forecast Period: | 2023 to 2033 |

| Forecast Period CAGR 2023 to 2033 : | 4.99% |

| 2033 Value Projection: | USD 5.14 Billion |

| Historical Data for: | 2019-2022 |

| No. of Pages: | 230 |

| Tables, Charts & Figures: | 115 |

| Segments covered: | By Raw Material, By Production, and COVID-19 Impact Analysis |

| Companies covered:: | Endurance Group, Castwel Auto Parts Pvt. Ltd., Sandhar Technologies Ltd., Dynacast, Gibbs Die Casting Group, Kinetic Die Casting Company, Mino Industry USA INC., Ningbo Parison Die Casting Co Ltd., Raltor Metal Technik India Pvt. Ltd., Rockman Industries Ltd., and others key players |

| Pitfalls & Challenges: | COVID-19 Empact, Challenges, Future, Growth, & Analysis |

Get more details on this report -

Driving Factors

Growing efforts to reduce carbon emissions and increasing government actions to encourage energy conservation are driving growth in the Germany automotive parts die-casting market. The recycling of zinc and aluminum automotive components made through die casting can reduce the generation of excessive waste by creating new products. The desire for high-performing, dependable, and easy-to-maintain cars is increasing in Germany as living standards rise. The strong presence of top automotive part producers and their growing dedication and financial input toward improving their product offerings are contributing to the market expansion in the country. Increasing financial resources allocated to enhance metal thermal treatment processes, coupled with ample metal availability, well-developed infrastructure, and a skilled workforce, are providing lucrative market growth prospects. Furthermore, there is a growing trend in Germany towards using integrated die-casting methods for manufacturing automotive components.

Restraining Factors

Significant upfront expenses and costs for equipment and infrastructure. Less design flexibility when compared with other manufacturing methods. Concerns regarding the environment associated with the extraction and disposal of metals. Fluctuations in the prices of raw materials, especially aluminum.

Market Segmentation

The Germany automotive parts die-casting market share is classified into raw material and production.

- The aluminum segment is expected to hold the largest market share through the forecast period.

The Germany automotive parts die-casting market is segmented by raw material into aluminum, zinc, magnesium, and others. Among them, the aluminum segment is expected to hold the largest market share through the forecast period. Aluminum die castings are both resistant to corrosion and light in weight, offering superior electrical and thermal conductivity as well as strong durability. Aluminum die castings maintain their shape and strength at elevated temperatures due to their dimensional stability. In addition, the aluminum high-pressure die-casting method enables the rapid production of near-net shapes. Moreover, aluminum die-cast items enhance the vehicle's performance by decreasing weight and boosting fuel efficiency.

- The pressure die-casting segment dominates the market with the largest market share over the predicted period.

The Germany automotive parts die-casting market is segmented by production into pressure die-casting, vacuum die-casting, squeeze die-casting, and semi-solid die-casting. Among them, the pressure die-casting segment dominates the market with the largest market share over the predicted period. Due to the reliable, affordable, and speedy manufacturing process used to produce metal components in large quantities. The technology is perfect for making magnesium and aluminum automotive castings such as gearbox casings, engine mounts, engine blocks, and oil sumps. The demand for die casting in the Germany automotive parts market is rising as there is a growing need to produce automotive parts in large quantities, resulting from the increase in vehicle ownership.

Competitive Analysis:

The report offers the appropriate analysis of the key organizations/companies involved within the Germany automotive parts die-casting market along with a comparative evaluation primarily based on their product offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborative analysis focusing on the current news and developments of the companies, which includes product development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

List of Key Companies

- Endurance Group

- Castwel Auto Parts Pvt. Ltd.

- Sandhar Technologies Ltd.

- Dynacast

- Gibbs Die Casting Group

- Kinetic Die Casting Company

- Mino Industry USA INC.

- Ningbo Parison Die Casting Co Ltd.

- Raltor Metal Technik India Pvt. Ltd.

- Rockman Industries Ltd.

- Others

Key Target Audience

- Market Players

- Investors

- End-users

- Government Authorities

- Consulting And Research Firm

- Venture capitalists

- Value-Added Resellers (VARs)

Recent Developments

- In April 2022, BMW recently introduced state-of-the-art multi-plate die-casting technology at their BMW Group factory located in Landshut's light metal foundry. This innovation allows for the creation of component designs that are optimized for function, transforming the die-casting process. The advancement was made possible by creating cutting-edge gating and demolding systems, utilizing direct gating in multi-plate mold technology.

Market Segment

This study forecasts revenue at Germany, regional, and country levels from 2020 to 2033. Spherical Insights has segmented the Germany automotive parts die-casting market based on the below-mentioned segments:

Germany Automotive Parts Die Casting Market, By Raw Material

- Aluminium

- Zinc

- Magnesium

- Others

Germany Automotive Parts Die Casting Market, By Production

- Pressure Die-Casting

- Vacuum Die-Casting

- Squeeze Die-Casting

- Semi-solid Die-Casting

Need help to buy this report?