Germany Metal Fabrication Equipment Market Size, Share, and COVID-19 Impact Analysis, By Type (Cutting, Machining, Welding, Bending, and Others), By Application (Job Shops, Automotive, Aerospace & Defense, Mechanical Application, and Others), and Germany Metal Fabrication Equipment Market Insights, Industry Trend, Forecasts to 2033

Industry: Advanced MaterialsGermany Metal Fabrication Equipment Market Insights Forecasts to 2033

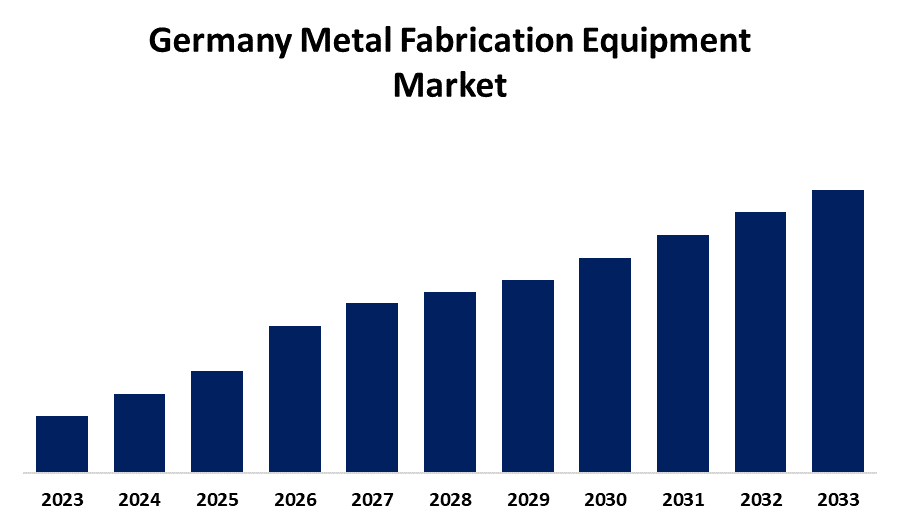

- The Germany Metal Fabrication Equipment Market is growing at a CAGR of 4.4% from 2023 to 2033

- The Germany Metal Fabrication Equipment Market Size is expected to hold a significant share by 2033

Get more details on this report -

The Germany Metal Fabrication Equipment Market is anticipated to hold a significant share by 2033, growing at a CAGR of 4.4% from 2023 to 2033. The expanding aviation & automobile industries and technological innovations revolutionizing metal fabrication processes are driving the metal fabrication equipment market in the Germany.

Market Overview

Metal fabrication equipment market is the industry encompassing the need for machinery, tools, and equipment used in shaping, cutting, joining, and assembling metal components and structures. Metal fabrication equipment refers to the wide array of tools and machinery used for shaping, cutting, and assembling metal parts and structures as per specific design requirements. The process involves bending, cutting, and assembling metal to create structures. The surging adoption of robotics, computer-aided engineering, and ERP software in metal fabrication makes manufacturing facilities safe, enhances productivity, and reduces labor costs. Businesses in metal fabrication are expanding their prefabricated constructed products portfolios to enhance their revenue streams. Advancements in the field of automation tools and robotics, adoption of automated fabrication process, and shifting trends in finance and manufacturing sectors are all the factors that are offering market growth opportunity of metal fabrication equipment.

Report Coverage

This research report categorizes the market for the Germany metal fabrication equipment market based on various segments and regions and forecasts revenue growth and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the Germany metal fabrication equipment market. Recent market developments and competitive strategies such as expansion, product launch, and development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the Germany metal fabrication equipment market.

Germany Metal Fabrication Equipment Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2023 |

| Forecast Period: | 2023 - 2033 |

| Forecast Period CAGR 2023 - 2033 : | 4.4% |

| Historical Data for: | 2019-2022 |

| No. of Pages: | 220 |

| Tables, Charts & Figures: | 113 |

| Segments covered: | By Application, By Type |

| Companies covered:: | Amada Co. Ltd., Atlas Copco AB, BTD Manufacturing, Bystronic Laser AG, Colfax Corp., DMG MORI Co. Ltd., Others, |

| Pitfalls & Challenges: | COVID-19 Empact,Challenges, Future, Growth, & Analysis |

Get more details on this report -

Driving Factors

The expanding aviation and automobile industries are responsible for driving market demand. Metal fabrication is used in the automotive industry for car bodies & frames, car customization & modification, vintage car restoration, and building roll cages. Further, sheet metal fabrication enables the creation of aircraft parts and components with precision, speed, and cost-effectiveness in the aviation industry. In addition, the trends and technologies involved in metal fabrication, such as automation& robotics, 3D printing, computer-aided design and manufacturing, additive manufacturing, IoT integration, and industry 4.0 technologies, are propelling the market growth.

Restraining Factors

The scarcity of qualified personnel and advancement in additive construction technologies are restraining the metal fabrication market. Further, the high initial investment required for manufacturing business leads to hamper market growth.

Market Segmentation

The Germany metal fabrication equipment market share is classified into type and application.

- The cutting segment dominated the market with the largest revenue share in 2023 and is expected to grow at a significant CAGR during the projected timeframe.

Based on the type, the Germany metal fabrication equipment market is divided into cutting, machining, welding, bending, and others. Among these, the cutting segment dominated the market with the largest revenue share in 2023 and is expected to grow at a significant CAGR during the projected timeframe. Cutting segment is undergoing digital transformation with the use of advanced tools and technologies such as CNC machines, press brakes, roll forming machines, and automated systems. The growing need for automatic metal-cutting technologies and the development of building & construction industries, along with rising implementation in Industry 4.0 systems, are propelling the market demand.

- The automotive segment dominates the Germany metal fabrication equipment market and is expected to grow at a significant CAGR during the forecast period.

Based on the application, the Germany metal fabrication equipment market is divided into job shops, automotive, aerospace & defense, mechanical application, and others. Among these, the automotive segment dominates the Germany metal fabrication equipment market and is expected to grow at a significant CAGR during the forecast period. Metal fabrication enables the creation of lightweight yet strong vehicle components such as body panels, frames, and engine parts via the process of stamping, welding, and CNC machining. The continuous evolution of design and material combinations in automobile manufacturing is driving market growth in the automotive segment.

Competitive Analysis:

The report offers the appropriate analysis of the key organizations/companies involved within the Germany metal fabrication equipment market along with a comparative evaluation primarily based on their product offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborative analysis focusing on the current news and developments of the companies, which includes product development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

List of Key Companies

- Amada Co. Ltd.

- Atlas Copco AB

- BTD Manufacturing

- Bystronic Laser AG

- Colfax Corp.

- DMG MORI Co. Ltd.

- Others

Key Target Audience

- Market Players

- Investors

- End-users

- Government Authorities

- Consulting And Research Firm

- Venture capitalists

- Value-Added Resellers (VARs)

Market Segment

This study forecasts revenue at Germany, regional, and country levels from 2020 to 2033. Spherical Insights has segmented the Germany Metal Fabrication Equipment Market based on the below-mentioned segments:

Germany Metal Fabrication Equipment Market, By Type

- Cutting

- Machining

- Welding

- Bending

- Others

Germany Metal Fabrication Equipment Market, By Application

- Job Shops

- Automotive

- Aerospace & Defense

- Mechanical Application

- Others

Need help to buy this report?