Global Industrial Boiler Maintenance Market By Product (Fire Tube, Water Tube), By Application (Food Processing, Pulp & Paper, Chemical, Refinery, Primary Metal), By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), And Segment Forecasts, By Geographic Scope And Forecast to 2033

Industry: Energy & PowerGlobal Industrial Boiler Maintenance Market Insights Forecasts to 2033

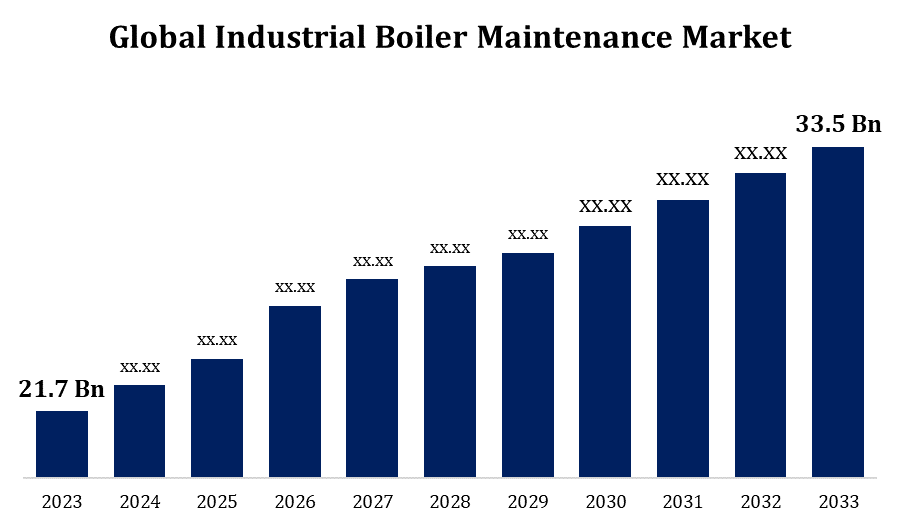

- The Global Industrial Boiler Maintenance Market Size was valued at USD 21.7 Billion in 2023.

- The Market Size is Growing at a CAGR of 4.44% from 2023 to 2033

- The Worldwide Industrial Boiler Maintenance Market Size is Expected to reach USD 33.5 Billion By 2033

- Asia Pacific is Expected To Grow the fastest during the forecast period

Get more details on this report -

The Global Industrial Boiler Maintenance Market is Expected To reach USD 33.5 Billion by 2033, at a CAGR of 4.44% during the forecast period 2023 to 2033.

Industrial boilers are critical to power generating and manufacturing processes. Regular maintenance guarantees effective operation, lowering fuel consumption and operating costs, which is becoming more important as energy prices increase and environmental concerns develop. Stricter environmental and safety standards around the world are driving the need for thorough boiler maintenance. To avoid fines and legal liability, industries must comply with emission regulations and safety requirements. The use of predictive analytics, IoT, and digital twins is revolutionising boiler maintenance. These technologies offer real-time monitoring and predictive maintenance, which lowers downtime and operational expenses.

Global Industrial Boiler Maintenance Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2023 |

| Market Size in 2023 : | USD 21.7 Billion |

| Forecast Period: | 2023 – 2033 |

| Forecast Period CAGR 2023 – 2033 : | 4.44% |

| 023 – 2033 Value Projection: | USD 33.5 Billion |

| Historical Data for: | 2019 - 2022 |

| No. of Pages: | 200 |

| Tables, Charts & Figures: | 110 |

| Segments covered: | By Product, By Application, By Region, By Geographic Scope |

| Companies covered:: | Thermax Ltd., Siemens AG, Bharat Heavy Electricals Ltd., Forbes Marshall, Mitsubishi Heavy Industries, Ltd., Harbin Electric Corporation, Cheema Boilers Limited, IHI Corporation, AC Boilers, Dongfang Electric Corporation Ltd., and other key vendors |

| Pitfalls & Challenges: | Covid-19 Impact, Challenge, Future,Growth and Analysis |

Get more details on this report -

Industrial Boiler Maintenance Market Value Chain Analysis

The industrial boiler maintenance market value chain involves various stages and stakeholders, from raw material suppliers of metals, alloys, insulation materials, and chemicals, to component manufacturers of boilers and auxiliary equipment. It includes technology and equipment providers offering diagnostic tools and maintenance machinery, as well as engineering firms and consultants for installation and commissioning. Maintenance and service providers handle routine inspections, repairs, and emergency services, while water treatment companies and chemical providers ensure optimal water quality. Monitoring and diagnostic services, including IoT-based solutions and data analytics, enable predictive maintenance. Regulatory compliance is ensured by inspection and certification bodies, supported by compliance consultants. End-use industries such as manufacturing, power generation, chemical, petrochemical, and food and beverage rely on these services to maintain boiler efficiency, safety, and longevity.

Industrial Boiler Maintenance Market Opportunity Analysis

Several critical reasons drive the industrial boiler maintenance industry, creating considerable opportunity. For example, the increasing industrialization and expansion of manufacturing sectors around the world necessitate dependable and effective boiler operations, necessitating regular maintenance and repair services. Second, strict environmental rules and safety requirements compel enterprises to use sophisticated maintenance methods in order to comply, hence increasing demand for specialised maintenance services and technologies. The increased emphasis on energy efficiency and cost reduction pushes the adoption of predictive maintenance and IoT-based monitoring solutions, creating opportunities for technology providers to create and integrate smart maintenance systems. Furthermore, the ageing infrastructure of industrial boilers demands periodic servicing and improvements, which drives up demand in this industry.

Market Dynamics

Industrial Boiler Maintenance Market Dynamics

Rising investments across the industrial sector

Rising investments in the industrial sector are considerably boosting the industrial boiler maintenance industry. Manufacturing, power generation, chemicals, petrochemicals, and food and beverage industries are all spending more in advanced maintenance procedures to safeguard their boiler systems' efficiency, dependability, and lifespan. Companies are investing in regular maintenance and advanced diagnostic technologies to improve boiler performance, reduce downtime, and cut operational expenses. Efficient boilers result in significant savings in fuel usage and maintenance costs. Many industrial establishments have older boiler systems that require regular maintenance and updates. Investments are being directed towards renovating and retrofitting these ageing boilers to improve their efficiency and performance, ensuring they meet current standards.

Restraints & Challenges

Regular maintenance and repair of industrial boilers can be costly, especially for older systems that need frequent servicing. The high cost of advanced diagnostic tools, professional labour, and replacement parts can put a strain on finances, particularly in small and medium-sized businesses. There is a considerable scarcity of skilled technicians and engineers versed in the most recent boiler maintenance technology and techniques. This gap can cause maintenance delays, lower service quality, and greater downtime in industrial processes. The growing complexity of modern boilers, which use innovative materials and technology, might make maintenance more difficult. Specialised knowledge and equipment are necessary to successfully service these systems, which increases the difficulty and cost of maintenance.

Regional Forecasts

North America Market Statistics

Get more details on this report -

North America is anticipated to dominate the Industrial Boiler Maintenance Market from 2023 to 2033. Stringent environmental and safety requirements, such as the Clean Air Act in the United States and similar restrictions in Canada, need frequent maintenance to ensure that boilers function within allowable emission levels, increasing demand for maintenance services. Furthermore, many industrial buildings use older boiler systems that require regular maintenance and upgrades to be efficient and compliant with current requirements. The usage of modern technologies, such as IoT, AI, and predictive maintenance solutions, is increasing, allowing for real-time monitoring and diagnostics, which improves maintenance efficiency and reduce downtime. Furthermore, North American enterprises place a high value on energy efficiency and sustainability, with regular maintenance playing an important role in improving boiler performance, reducing fuel consumption, and lowering emissions.

Asia Pacific Market Statistics

Asia Pacific is witnessing the fastest market growth between 2023 to 2033. Asia-Pacific is seeing significant industrialization, particularly in growing economies such as China, India, Indonesia, and Vietnam. This growth is driving up demand for industrial boilers and, as a result, their upkeep. Many industrial enterprises in the region use older boiler systems that require regular maintenance and upgrades to ensure operational efficiency and safety. With rising energy costs and a growing emphasis on sustainability, enterprises are investing in routine boiler maintenance to improve energy efficiency, lower fuel usage, and reduce carbon footprints. The transition to renewable energy sources, as well as the integration of biomass and other sustainable boilers, open up new maintenance options. The growing emphasis on sustainability and decreasing carbon emissions will drive demand for energy-efficient and environmentally friendly boiler repair procedures.

Segmentation Analysis

Insights by Product

The water tube segment accounted for the largest market share over the forecast period 2023 to 2033. Water tube boilers are widely employed in a variety of industries due to their efficiency, safety, and capacity to manage high-pressure steam systems. The expanding use of water tube boilers in industries such as electricity generation, chemical processing, and oil and gas is driving up demand for boiler-specific maintenance services. Industries are increasingly prioritising operational efficiency and dependability in order to reduce downtime and increase output. Regular maintenance of water tube boilers is required to avoid malfunctions, optimise performance, and extend equipment life. As businesses seek to improve their operating efficiency, the need for proactive maintenance services for water tube boilers is increasing.

Insights by Application

The food processing segment is dominating the market with the largest market share over the forecast period 2023 to 2033. As food processing companies strive to increase efficiency and lower labour costs, there is an increasing trend towards process automation. Automated boiler monitoring and maintenance systems provide more control and efficiency in controlling boiler operations, driving up demand for integrated maintenance solutions customised to the needs of food processing facilities. The use of modern technologies such as IoT, AI, and predictive maintenance solutions is changing maintenance methods in the food processing industry. Real-time monitoring, remote diagnostics, and predictive analytics allow for early defect detection, proactive maintenance planning, and maintenance schedule optimisation, all of which contribute to better boiler system efficiency and reliability.

Recent Market Developments

- In October 2023, Babcock & Wilcox got a $11 million maintenance contract for Newfoundland and Labrador Hydro's Holyrood Thermal Generating Station.

Competitive Landscape

Major players in the market

- Thermax Ltd.

- Siemens AG

- Bharat Heavy Electricals Ltd.

- Forbes Marshall

- Mitsubishi Heavy Industries, Ltd.

- Harbin Electric Corporation

- Cheema Boilers Limited

- IHI Corporation

- AC Boilers

- Dongfang Electric Corporation Ltd.

Market Segmentation

This study forecasts revenue at global, regional, and country levels from 2023 to 2033.

Industrial Boiler Maintenance Market, Product Analysis

- Fire Tube

- Water Tube

Industrial Boiler Maintenance Market, Application Analysis

- Food Processing

- Pulp & Paper

- Chemical

- Refinery

- Primary Metal

Industrial Boiler Maintenance Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of Middle East & Africa

Frequently Asked Questions (FAQ)

-

1. What is the market size of the Industrial Boiler Maintenance Market?The global Industrial Boiler Maintenance Market is expected to grow from USD 21.7 billion in 2023 to USD 33.5 billion by 2033, at a CAGR of 4.44% during the forecast period 2023-2033.

-

2. Who are the key market players of the Industrial Boiler Maintenance Market?Some of the key market players of the market are Thermax Ltd.; Siemens AG; Bharat Heavy Electricals Ltd.; Forbes Marshall; Mitsubishi Heavy Industries, Ltd.; Harbin Electric Corporation; Cheema Boilers Limited; IHI Corporation; AC Boilers; Dongfang Electric Corporation Ltd.

-

3. Which segment holds the largest market share?The food processing segment holds the largest market share and is going to continue its dominance.

-

4. Which region is dominating the Industrial Boiler Maintenance Market?North America is dominating the Industrial Boiler Maintenance Market with the highest market share.

Need help to buy this report?