Japan Factory Automation and Industrial Controls Market Size, Share, and COVID-19 Impact Analysis, By Types (Industrial Control Systems (Supervisory Control & Data Acquisition (SCADA), Product Lifecycle Management (PLM), Manufacturing Execution System (MES), Human Machine Interface (HMI), Distributed Control System (DCS), Programmable Logic Controller (PLC), and Others) and Field Devices (Electric Motors, Safety Systems, Machine Vision, Industrial Robotics, Sensors & Transmitters, and Others), By End-user Industry (Chemical & Petrochemical, Oil & Gas, Power & Utilities, Food & Beverage, Automotive & Transportation, Pharmaceutical, and Others), and Japan Factory Automation and Industrial Controls Market Insights Forecasts 2022 – 2032

Industry: Semiconductors & ElectronicsJapan Factory Automation and Industrial Controls Market Insights Forecasts to 2032

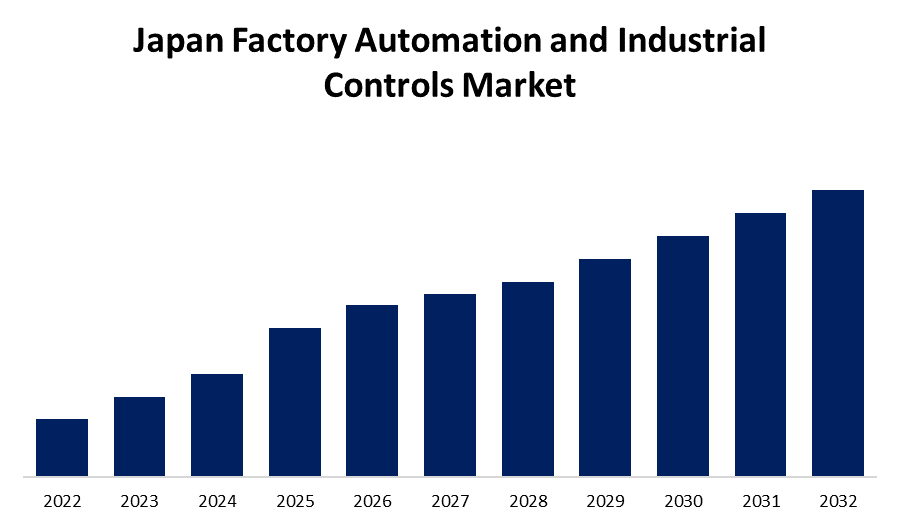

- The Market Size is Growing at a CAGR of 10.78% from 2022 to 2032.

- The Japan Factory Automation and Industrial Controls Market Size is Expected to Hold a Significant Share by 2032.

Get more details on this report -

The Japan Factory Automation and Industrial Controls Market Size is Expected to hold a significant share by 2032, at a CAGR of 10.78% during the forecast period 2022 to 2032.

Market Overview

Factory automation and industrial control systems may include computers, equipment, and information technology software that reduces human involvement in the execution of various processes in any industry. The automation system helps simplify processes, increase productivity, eliminate errors, and improve overall operational efficiency. This technology is in high demand due to the growing emphasis on cost reduction and the increasing need for precision in many operations. Distributed control systems (DCS), supervisory control and data acquisition (SCADA), robotic arms, conveyance systems, manufacturing execution systems (MES), conveyor belts, programmable logic controllers (PLC), and enterprise resource planning (ERP) solutions are examples of industrial control and factory automation systems. Automation-manufactured products not only have higher quality, but they also have lower operational costs, increasing the product's overall profitability margin. Automation also helps to conserve energy. Automation is now an important part of the manufacturing, oil and gas, electricity, mining, railway, and shipping industries. Another factor driving the growth of the factory automation and industrial controls market is labor scarcity, the need for high yield and production, and a greater emphasis on improving efficiency and accuracy to achieve high productivity.

Report Coverage

This research report categorizes the market for the Japan factory automation and industrial controls market based on various segments and regions forecasts revenue growth and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the Japan factory automation and industrial controls market. Recent market developments and competitive strategies such as expansion, product launch, and development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the Japan factory automation and industrial controls market.

Japan Factory Automation and Industrial Controls Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2022 |

| Forecast Period: | 2022-2032 |

| Forecast Period CAGR 2022-2032 : | 10.78% |

| Historical Data for: | 2018-2021 |

| No. of Pages: | 200 |

| Tables, Charts & Figures: | 120 |

| Segments covered: | By Types, By End-user Industry, and COVID-19 Impact Analysis. |

| Companies covered:: | Schneider Electric SE, Rockwell Automation Inc., Honeywell International Inc., Emerson Electric Company, ABB Ltd, Mitsubishi Electric Corporation, Siemens AG, Omron Corporation, Yokogawa Electric Corporation, Yasakawa Electric Corporation, Fanuc Corporation, Nidec Corporation, Fuji Electric Co. Ltd., Seiko Epson Corporation, Shibaura Machine CO and Other Key Vendors. |

| Pitfalls & Challenges: | COVID-19 Empact, Challenge, Future, Growth, & Analysis |

Get more details on this report -

Driving Factors

Analytics, cloud, and mobility technologies are assisting organizations in more efficiently meeting their goals. Furthermore, the penetration of the Internet of Things (IoT) in factory automation is driving the growth of smart manufacturing to embrace and adopt the benefits of internet connectivity. Technological advancements, expanding economic and infrastructure opportunities, and rising demand for operational efficiency all have an impact on factory automation. By ushering in a new era of economic growth, automation is expected to benefit the country and businesses. It is anticipated that it will have a significant impact on a wide range of businesses, shareholders, business models, and favorable government regulations to encourage industry adoption.

Restraining Factors

Field instruments and other factory automation solutions are widely used for a variety of applications in industries such as oil and gas and semiconductor & electronics, including measurement of process parameters such as pressure, level, and flow of oil and gas; as a result, any impact on the country's petroleum and semiconductor markets is expected to have an impact on the growth of the factory automation and industrial controls market.

Market Segment

- In 2022, the distributed control segment accounted for the significant revenue share over the forecast period.

Based on the types, the Japan factory automation and industrial controls market is segmented into industrial control systems and field devices. The industrial control systems are further segregated into supervisory control & data acquisition (SCADA), product lifecycle management (PLM), manufacturing execution system (MES), human-machine interface (HMI), distributed control system (DCS), programable logic controller (PLC), and others, and the field devices are further segregated into Among these, the distributed control segment has the significant revenue share over the forecast period. Distributed control systems (DCS) are process-oriented platforms that act as a centralized master controller for a facility's manufacturing operations by utilizing a network of interconnected sensors, actuators, controllers, and terminals. As such, a DCS focuses on process control and monitoring while also providing facility operators with a centralized view of all facility operations. DCS enables the implementation of advanced process automation strategies because it operates on a closed-loop control platform. Therefore, DCS is best suited for managing operations at a single facility or factory. A DCS is also essential for increasing the visibility of a facility's day-to-day operational processes.

In 2022, the oil & gas segment accounted for the significant revenue share over the forecast period.

Based on the end-user industry, the Japan factory automation and industrial controls market is segmented into chemical & petrochemical, oil & gas, power & utilities, food & beverage, automotive & transportation, pharmaceutical, and others. Among these, the oil & gas segment accounted for the significant revenue share over the forecast period. Since the oil and gas industry is subject to several government regulations for safety, plant dependability, and efficiency, industrial controls are used to ensure safety in remote terminal units (RTU) and pumping and compression stations. To maintain safety and environmental purity while increasing production efficiency, the industry is rapidly implementing industrial control solutions. Automation aids in the integration of information and control, power, and safety solutions to meet the demands of low-cost energy and stringent government regulations. To monitor gas and liquid measurement data from the wellhead to production, storage, transportation, processing, and points of sale, upstream and midstream enterprises required critical data management skills.

Competitive Analysis:

The report offers the appropriate analysis of the key organizations/companies involved within the Japan Factory Automation and Industrial Controls Market along with a comparative evaluation primarily based on their product offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborative analysis focusing on the current news and developments of the companies, which includes product development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

List of Key Companies

- Schneider Electric SE

- Rockwell Automation Inc.

- Honeywell International Inc.

- Emerson Electric Company

- ABB Ltd

- Mitsubishi Electric Corporation

- Siemens AG

- Omron Corporation

- Yokogawa Electric Corporation

- Yasakawa Electric Corporation

- Fanuc Corporation

- Nidec Corporation

- Fuji Electric Co. Ltd.

- Seiko Epson Corporation

- Shibaura Machine CO

Key Target Audience

- Market Players

- Investors

- End-users

- Government Authorities

- Consulting and Research Firm

- Venture capitalists

- Value-Added Resellers (VARs)

Recent Development

- In May 2022, Kawasaki Heavy Industries created a humanoid robot that works outside of factories and displayed it in Tokyo. The company has a Group Vision 2030, which calls for robotics technology in two areas: safety and security in remote societies, and future mobility. The company displayed the "HINOTORI," a Medic-aid or surgical support robot, in the area of remote society safety and security.

- In April 2022, Yaskawa Company in Japan developed an industrial robot with artificial intelligence that recognizes the color and shape of objects and transports them to their proper location. The company is expanding into new markets, such as the automobile industry and parts manufacturing.

Market Segment

This study forecasts revenue at regional, and country levels from 2021 to 2032. Spherical Insights has segmented the Japan Factory Automation and Industrial Controls Market based on the below-mentioned segments:

Japan Factory Automation and Industrial Controls Market, By Types

- Industrial Control Systems

- Supervisory Control & Data Acquisition (SCADA)

- Product Lifecycle Management (PLM)

- Manufacturing Execution System (MES)

- Human Machine Interface (HMI)

- Distributed Control System (DCS)

- Programmable Logic Controller (PLC)

- Others

- Field Devices

- Electric Motors

- Safety Systems

- Machine Vision

- Industrial Robotics

- Sensors & Transmitters

- Others

Japan Factory Automation and Industrial Controls Market, By End-user Industry

- Chemical & Petrochemical

- Oil & Gas

- Power & Utilities

- Food & Beverage

- Automotive & Transportation

- Pharmaceutical

- Others

Need help to buy this report?