Global Metal Casting Market Size, Share, and COVID-19 Impact Analysis, By Material Type (Cast Iron, Aluminum, Stainless Steel, Zinc, Magnesium), By Process (Sand Casting, Die Casting, Shell Mold Casting, Gravity Casting, Vacuum Casting), By End-Use (Automotive & Transportation, Building & Construction, Mining, Equipment & Machine, Consumer Goods), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2023 - 2033

Industry: Advanced MaterialsGlobal Metal Casting Market Insights Forecasts to 2033

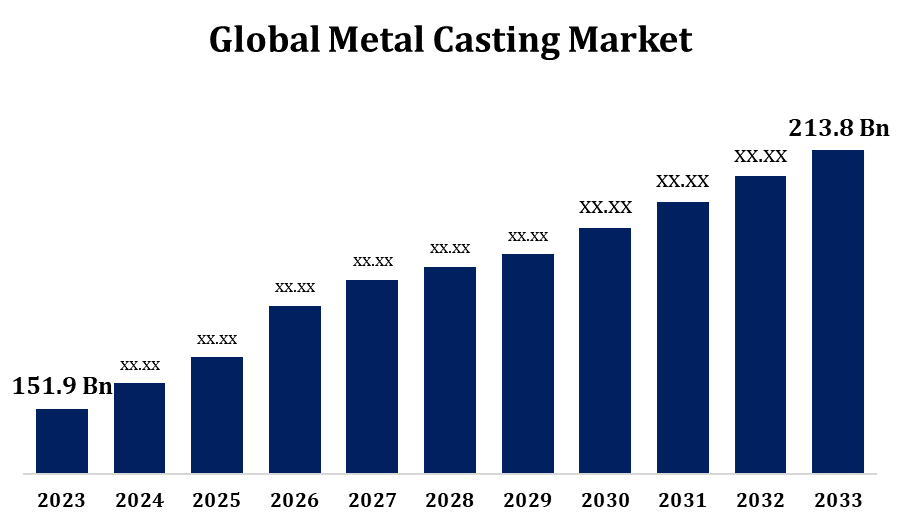

- The Metal Casting Market Size was valued at USD 151.9 Billion in 2023.

- The Market Size is Growing at a CAGR of 3.48% from 2023 to 2033.

- The Global Metal Casting Market Size is Expected to reach USD 213.8 Billion By 2033.

- Asia Pacific Size is Expected to Grow the Fastest during the Forecast period.

Get more details on this report -

The Global Metal Casting Market Size is Expected to reach USD 213.8 billion By 2033, at a CAGR of 3.48% during the Forecast period 2023 to 2033.

The metal casting market is experiencing steady growth, driven by rising demand in industries such as automotive, aerospace, construction, and industrial machinery. Metal casting, a process of pouring molten metal into a mold to create complex shapes, is widely used due to its cost-effectiveness and efficiency in mass production. The increasing shift toward lightweight and high-performance materials, particularly in the automotive sector for fuel efficiency and emission reduction, is fueling market expansion. Additionally, advancements in casting technologies, including 3D printing and automation, are enhancing precision and reducing production costs. However, challenges such as environmental concerns and high initial investment costs may restrain growth. The Asia-Pacific region dominates the market, led by China and India, due to rapid industrialization and rising infrastructure investments.

Metal Casting Market Value Chain Analysis

The metal casting market value chain consists of several key stages, starting with raw material suppliers who provide metals such as iron, aluminum, steel, and copper. Foundries and casting manufacturers then process these materials through various casting techniques, including sand casting, die casting, and investment casting, to produce desired components. Equipment and technology providers supply advanced machinery, automation solutions, and quality control systems to enhance efficiency. Distributors and suppliers connect manufacturers with end-users in industries like automotive, aerospace, construction, and machinery. Finally, end-users integrate cast components into final products. Recycling and waste management play a crucial role in sustainability by reprocessing scrap metal. Technological advancements, efficient supply chain management, and regulatory compliance are essential for optimizing productivity and maintaining competitive advantage in the market.

Metal Casting Market Opportunity Analysis

The metal casting market presents significant opportunities driven by technological advancements, increasing industrialization, and sustainability trends. The growing demand for lightweight and high-strength materials, especially in the automotive and aerospace sectors, is creating new prospects for advanced casting techniques like precision casting and 3D printing. Emerging economies, particularly in Asia-Pacific, offer lucrative opportunities due to rapid infrastructure development and expanding manufacturing activities. The shift toward eco-friendly casting processes and the use of recycled metals align with global sustainability goals, reducing waste and energy consumption. Additionally, automation and digitalization in foundries enhance productivity and quality, attracting investments in smart manufacturing. Companies focusing on innovation, cost-effective production, and customization will gain a competitive edge in this evolving market landscape.

Global Metal Casting Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2023 |

| Market Size in 2023: | USD 151.9 Billion |

| Forecast Period: | 2023-2033 |

| Forecast Period CAGR 2023-2033 : | 3.48% |

| 2033 Value Projection: | USD 213.8 Billion |

| Historical Data for: | 2019-2022 |

| No. of Pages: | 230 |

| Tables, Charts & Figures: | 105 |

| Segments covered: | By Material Type, By Process, By End-Use, By Region and COVID-19 Impact Analysis |

| Companies covered:: | POSCO, Dynacast, Arconic, Ryobi Limited, Endurance Technologies Limited, Alcast Technologies, UNI Abex, MES, Inc., CALMET, Hitachi, Ltd., and others key vedors. |

| Pitfalls & Challenges: | COVID-19 Empact, Challenges, Future, Growth, & Analysis |

Get more details on this report -

Market Dynamics

Metal Casting Market Dynamics

The expanding manufacturing sector is expected to drive market growth

The expanding manufacturing sector is expected to drive metal casting market growth as industries increasingly rely on cast components for complex and high-performance applications. The automotive industry, in particular, is a major contributor, with rising demand for lightweight and fuel-efficient vehicles driving the need for precision-cast parts. Similarly, aerospace, construction, and industrial machinery sectors are witnessing increased adoption of advanced casting techniques to enhance durability and efficiency. Emerging economies, especially in Asia-Pacific, are investing in large-scale manufacturing, further fueling demand for metal casting. Additionally, technological advancements such as automation, 3D printing, and improved alloy compositions are improving casting efficiency and quality. As manufacturers focus on cost-effective and sustainable production, the metal casting market is poised for significant expansion.

Restraints & Challenges

Environmental concerns related to high energy consumption, carbon emissions, and waste generation in foundries pose regulatory and sustainability challenges. Strict government regulations on emissions and waste disposal require costly compliance measures, increasing operational expenses. Additionally, fluctuating raw material prices, particularly for metals like aluminum, steel, and copper, create cost uncertainties for manufacturers. The industry also faces skilled labor shortages, as casting processes require expertise that is becoming scarce due to workforce aging and limited training programs. Furthermore, competition from alternative manufacturing methods, such as additive manufacturing (3D printing) and advanced machining, is putting pressure on traditional casting techniques.

Regional Forecasts

North America Market Statistics

Get more details on this report -

North America is anticipated to dominate the Metal Casting Market from 2023 to 2033. The region benefits from advanced manufacturing technologies, stringent quality standards, and a well-established supply chain. The U.S. leads the market due to its strong industrial base and increasing adoption of lightweight materials in automotive and aerospace applications. Additionally, the push for sustainable casting processes and the use of recycled metals are gaining traction, aligning with environmental regulations. Investments in automation, precision casting, and digital manufacturing are expected to enhance efficiency and competitiveness. Overall, North America's metal casting market remains resilient with steady growth prospects.

Asia Pacific Market Statistics

Asia Pacific is witnessing the fastest market growth between 2023 to 2033. India, and Japan lead the market due to their strong manufacturing base, cost-effective labor, and increasing demand for cast components. The region benefits from abundant raw materials and government initiatives supporting domestic manufacturing. Rising investments in construction, energy, and transportation further boost market expansion. To remain competitive, manufacturers are adopting automation, precision casting, and eco-friendly processes. With increasing demand for lightweight and high-performance materials, Asia-Pacific remains the dominant and fastest-growing region in the global metal casting market.

Segmentation Analysis

Insights by Material Type

The cast iron segment accounted for the largest market share over the forecast period 2023 to 2033. Cast iron is widely used in automotive, construction, machinery, and pipe manufacturing due to its excellent wear resistance, high compressive strength, and good machinability. The increasing demand for heavy machinery and infrastructure development, particularly in emerging economies, is driving market expansion. Additionally, advancements in casting techniques, such as improved mold designs and automated processes, enhance efficiency and product quality.

Insights by Process

The sand casting segment accounted for the largest market share over the forecast period 2023 to 2033. The increasing demand from industries such as automotive, aerospace, construction, and heavy machinery is fueling expansion. Advancements in sand mold technology, including improved binders and automation, enhance precision and efficiency. The rising trend of customized and low-volume production further supports market growth. Additionally, the adoption of eco-friendly and reusable sand materials aligns with sustainability initiatives, making sand casting an attractive option. The continued expansion of manufacturing activities, particularly in emerging economies, along with technological innovations in casting processes, ensures steady demand and long-term growth for the sand casting segment.

Insights by End Use

The Automotive & Transportation segment accounted for the largest market share over the forecast period 2023 to 2033. The growth is fueled by increasing vehicle production and the demand for lightweight, high-strength components. Automakers are increasingly using cast aluminum and other advanced alloys to improve fuel efficiency and meet stringent emission regulations. The shift toward electric vehicles (EVs) is further boosting demand for precision-cast components in battery housings, motor casings, and structural parts. Additionally, advancements in casting technologies, such as high-pressure die casting and automated processes, enhance production efficiency and quality. The growing adoption of hybrid and electric transportation, along with the expansion of commercial and passenger vehicle fleets globally, continues to create significant opportunities. Emerging markets in Asia-Pacific further accelerate segment growth due to rising automotive manufacturing activities.

Recent Market Developments

- In July 2023, the American Foundry Society (AFS) announced the launch of the AM for Metal Casting program, designed to enhance the adoption of additive manufacturing in metal casting. This initiative targets metal casters seeking to improve their products and processes through advanced additive manufacturing technologies.

Competitive Landscape

Major players in the market

- POSCO

- Dynacast

- Arconic

- Ryobi Limited

- Endurance Technologies Limited

- Alcast Technologies

- UNI Abex

- MES, Inc.

- CALMET

- Hitachi, Ltd.

Market Segmentation

This study forecasts revenue at global, regional, and country levels from 2023 to 2033.

Metal Casting Market, Material Type Analysis

- Cast Iron

- Aluminum

- Stainless Steel

- Zinc

- Magnesium

Metal Casting Market, Process Analysis

- Sand Casting

- Die Casting

- Shell Mold Casting

- Gravity Casting

- Vacuum Casting

Metal Casting Market, End Use Analysis

- Automotive & Transportation

- Building & Construction

- Mining

- Equipment & Machine

- Consumer Goods

Metal Casting Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

Frequently Asked Questions (FAQ)

-

1. What is the market size of the Metal Casting Market?The global Metal Casting Market is expected to grow from USD 151.9 billion in 2023 to USD 213.8 billion by 2033, at a CAGR of 3.48% during the forecast period 2023-2033.

-

2. Who are the key market players of the Metal Casting Market?Some of the key market players of the market are POSCO; Dynacast; Arconic; Ryobi Limited; Endurance Technologies Limited; Alcast Technologies; UNI Abex; MES, Inc.; CALMET; Hitachi, Ltd.

-

3. Which segment holds the largest market share?The sand casting segment holds the largest market share and is going to continue its dominance.

Need help to buy this report?