Global Metallocene Polyethylene (mPE) Market Size, Share, and COVID-19 Impact Analysis, By Product (mLLDPE, mHDPE, Others), By Application (Films, Sheets, Injection Moulding, Extrusion Coating, Others), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2023 - 2033

Industry: Chemicals & MaterialsGlobal Metallocene Polyethylene (mPE) Market Insights Forecasts to 2033

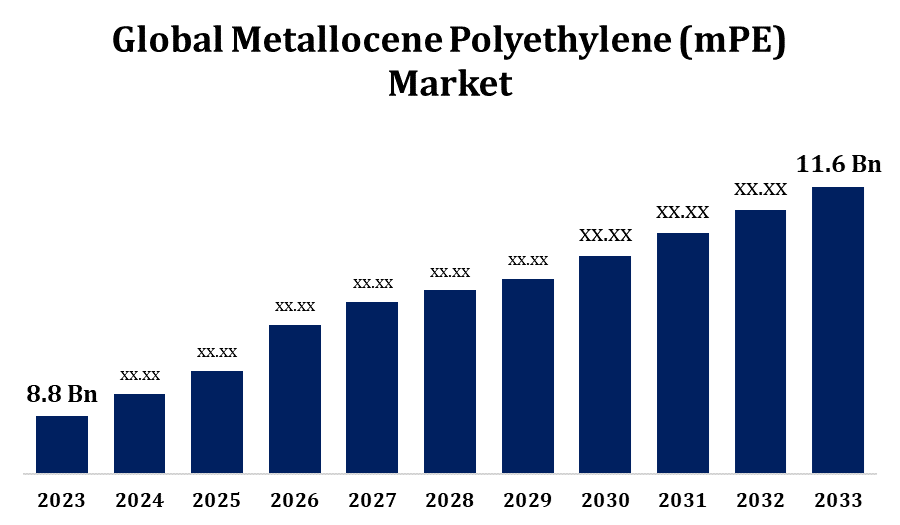

- The Metallocene Polyethylene (mPE) Market was valued at USD 8.8 billion in 2023.

- The Market is Growing at a CAGR of 2.80% from 2023 to 2033.

- The Global Metallocene Polyethylene (mPE) Market is Expected to reach USD 11.6 billion by 2033.

- Asia Pacific is Expected to Grow the fastest during the Forecast period.

Get more details on this report -

The Global Metallocene Polyethylene (mPE) Market is expected to reach USD 11.6 billion by 2033, at a CAGR of 2.80% during the forecast period 2023 to 2033.

The metallocene polyethylene (mPE) market is expanding, driven by its unique properties, such as enhanced toughness, clarity, and flexibility. mPE is a type of polyethylene produced using metallocene catalysts, which provide better control over polymer structure, resulting in superior performance characteristics compared to traditional polyethylene. This material is widely used in packaging, healthcare, automotive, and consumer goods sectors due to its high impact strength and resistance to punctures and tears. Growing demand for sustainable and high-performance packaging materials, particularly in food and pharmaceutical sectors, is boosting mPE market growth. Additionally, its recyclability aligns with increasing environmental concerns and regulations on single-use plastics. Key market players are investing in R&D to develop new mPE products, further driving market expansion.

Metallocene Polyethylene (mPE) Market Value Chain Analysis

The value chain for the metallocene polyethylene (mPE) market involves several critical stages, from raw material sourcing to end-user application. It begins with the extraction and refinement of ethylene, which serves as the primary feedstock. Metallocene catalysts are then integrated during the polymerization process to produce high-quality mPE with enhanced properties. This production stage typically involves leading petrochemical companies investing in advanced manufacturing technologies. Once produced, mPE resin is distributed to converters and processors who shape it into films, sheets, and other forms suitable for various applications like packaging, medical products, and consumer goods. Distributors and suppliers bridge the gap between manufacturers and end-users, ensuring consistent supply and meeting sector-specific requirements. The value chain is further influenced by R&D efforts, regulatory standards, and consumer demand for sustainable materials.

Global Metallocene Polyethylene (mPE) Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2023 |

| Market Size in 2023: | USD 8.8 billion |

| Forecast Period: | 2023-2033 |

| Forecast Period CAGR 2023-2033 : | 2.80% |

| 2033 Value Projection: | USD 11.6 billion |

| Historical Data for: | 2019-2022 |

| No. of Pages: | 230 |

| Tables, Charts & Figures: | 115 |

| Segments covered: | By Product, By Application, By Application and COVID-19 Impact Analysis |

| Companies covered:: | Dow Chemical (US), Chevron Philips (US), ExxonMobil (US), LyondellBasell (Netherlands), Borealis (Germany), Total (US), Univation Technologies (US), Ineos (UK), SABIC (Saudi Arabia), Formosa Plastics Corporation (Taiwan), Prime Polymer Co., Ltd. (Japan), Westlake Chemical Corporation (US), China Petrochemical Corporation (China), Nova Chemicals Corporation (Canada), Sasol Limited (South Africa), and others key players. |

| Pitfalls & Challenges: | COVID-19 Empact, Challenges, Future, Growth, & Analysis |

Get more details on this report -

Metallocene Polyethylene (mPE) Market Opportunity Analysis

The metallocene polyethylene (mPE) market presents significant opportunities, especially in the packaging, automotive, and healthcare sectors. Rising demand for durable and flexible packaging materials that improve shelf life and maintain product integrity is boosting mPE use in food and pharmaceutical packaging. mPE’s high puncture resistance, clarity, and recyclability make it an attractive choice, aligning with the global shift toward sustainable and eco-friendly packaging. Additionally, the automotive industry’s need for lightweight materials is encouraging the use of mPE films, which help improve fuel efficiency and reduce emissions. Innovations in metallocene catalyst technology are enhancing product quality and creating opportunities for specialized applications, while increasing R&D efforts and investments aim to expand the material’s properties and applications, further propelling market growth.

Market Dynamics

Metallocene Polyethylene (mPE) Market Dynamics

Metallocene polyethylene is becoming more and more in demand from the packaging sector

Metallocene polyethylene (mPE) is witnessing rising demand in the packaging sector, a key driver of its market growth. Known for its excellent strength, flexibility, and clarity, mPE is increasingly favored in applications requiring high-performance packaging, such as food, pharmaceuticals, and personal care products. Its superior impact and puncture resistance make it ideal for maintaining product safety, extending shelf life, and enhancing consumer appeal. Additionally, mPE's recyclability aligns with the industry’s shift toward sustainable materials, appealing to environmentally conscious brands and consumers. As the global need for flexible, durable, and lightweight packaging solutions intensifies, mPE is positioned to become an essential material in the sector. Innovations in metallocene catalyst technology are also boosting the quality of mPE, enabling tailored packaging solutions and expanding its adoption across diverse industries.

Restraints & Challenges

One primary issue is the high production cost of mPE compared to conventional polyethylene, driven by expensive metallocene catalysts and complex manufacturing processes. This cost factor can limit its adoption, especially in price-sensitive markets. Additionally, while mPE is valued for its recyclability, the lack of infrastructure for efficient recycling in many regions poses challenges for sustainable disposal and reuse. Furthermore, fluctuating raw material prices, particularly ethylene, can lead to unstable production costs, affecting market dynamics. Regulatory restrictions on plastic usage and environmental concerns also pressure the industry to innovate while ensuring compliance. To address these challenges, key players are investing in R&D to enhance production efficiency and explore sustainable alternatives, but hurdles remain in scaling these solutions.

Regional Forecasts

North America Market Statistics

Get more details on this report -

North America is anticipated to dominate the Metallocene Polyethylene (mPE) Market from 2023 to 2033. The region’s advanced manufacturing infrastructure and focus on innovation support the production and application of mPE in various sectors. In packaging, mPE’s strength, flexibility, and clarity make it ideal for food and pharmaceutical applications where durability and product safety are essential. The automotive industry also contributes to market expansion as it seeks lightweight, durable materials to improve fuel efficiency and reduce emissions. North America’s emphasis on sustainability further fuels demand, as mPE aligns with eco-friendly practices due to its recyclability. Leading market players are heavily investing in R&D to improve mPE properties and enhance production efficiency, positioning North America as a significant contributor to global mPE market growth.

Asia Pacific Market Statistics

Asia Pacific is witnessing the fastest market growth between 2023 to 2033. Emerging countries are major players, with expanding industries that require high-performance materials like mPE for durable, flexible, and lightweight applications. The packaging industry, especially in food and pharmaceuticals, is a significant driver as mPE’s clarity, strength, and puncture resistance enhance product safety and shelf life. Additionally, the region’s focus on industrialization and urbanization supports demand in construction and automotive applications where lightweight and resilient materials are valued. Regulatory pushes for sustainable materials and an increasing number of regional manufacturing facilities are also encouraging mPE adoption. As Asia-Pacific industrial sectors grow, the region is expected to become a key player in the global mPE market.

Segmentation Analysis

Insights by Type

The mLLDPE segment accounted for the largest market share over the forecast period 2023 to 2033. This growth is driven by mLLDPE’s unique properties, including high tensile strength, flexibility, and impact resistance, which make it ideal for diverse applications such as stretch films, packaging, and industrial films. The packaging industry, in particular, favors mLLDPE due to its exceptional clarity, puncture resistance, and lightweight characteristics, all of which enhance product protection and shelf appeal. Demand is also increasing as mLLDPE supports sustainability goals, being recyclable and enabling material reduction in packaging applications. Technological advancements in metallocene catalysts further refine mLLDPE’s performance, creating opportunities for innovation and expansion. As industries seek high-performance, eco-friendly materials, the mLLDPE segment is poised for substantial growth globally.

Insights by Application

The mPE films segment accounted for the largest market share over the forecast period 2023 to 2033. mPE films are valued for their excellent clarity, strength, flexibility, and puncture resistance, making them ideal for food, pharmaceutical, and consumer goods packaging. These films offer enhanced product protection, extended shelf life, and improved aesthetics, key factors that fuel their adoption in the packaging industry. Additionally, mPE films align with the increasing demand for sustainable materials due to their recyclability and lower material usage. Innovations in metallocene catalyst technology are further refining the properties of mPE films, expanding their application range. As global packaging requirements evolve toward more durable, lightweight, and eco-friendly materials, the mPE films segment is poised for continued expansion, particularly in regions like North America and Asia-Pacific.

Recent Market Developments

- On June 2019, Reliance Industries Limited (RIL) used Univation Technologies' UNIPOL PE Process to construct a new polyethylene plant capacity.

Competitive Landscape

Major players in the market

- Dow Chemical (US)

- Chevron Philips (US)

- ExxonMobil (US)

- LyondellBasell (Netherlands)

- Borealis (Germany)Total (US)

- Univation Technologies (US)

- Ineos (UK)

- SABIC (Saudi Arabia)

- Formosa Plastics Corporation (Taiwan)

- Prime Polymer Co., Ltd. (Japan)

- Westlake Chemical Corporation (US)

- China Petrochemical Corporation (China)

- Nova Chemicals Corporation (Canada)

- Sasol Limited (South Africa)

Market Segmentation

This study forecasts revenue at global, regional, and country levels from 2023 to 2033.

Metallocene Polyethylene (mPE) Market, Type Analysis

- mLLDPE

- mHDPE

- Others

Metallocene Polyethylene (mPE) Market, Application Analysis

- Films

- Sheets

- Injection Moulding

- Extrusion Coating

- Others

Metallocene Polyethylene (mPE) Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

Frequently Asked Questions (FAQ)

-

1. What is the Market Size of the Metallocene Polyethylene (mPE) Market?The global Metallocene Polyethylene (mPE) Market is expected to grow from USD 8.8 billion in 2023 to USD 11.6 billion by 2033, at a CAGR of 2.80% during the forecast period 2023-2033.

-

2. Who are the key Market players of the Metallocene Polyethylene (mPE) Market?Some of the key market players of the market are Dow Chemical (US), Chevron Philips (US), ExxonMobil (US), LyondellBasell (Netherlands), Borealis (Germany), Total (US), Univation Technologies (US), Ineos (UK), SABIC (Saudi Arabia), Formosa Plastics Corporation (Taiwan), Prime Polymer Co., Ltd. (Japan), Westlake Chemical Corporation (US), China Petrochemical Corporation (China), Nova Chemicals Corporation (Canada), and Sasol Limited (South Africa).

-

3. Which segment holds the largest market share?The mPE films segment holds the largest market share and is going to continue its dominance.

-

4. Which region dominates the Metallocene Polyethylene (mPE) Market?North America dominates the Metallocene Polyethylene (mPE) Market and has the highest market share.

Need help to buy this report?