Global Methanol-to-Olefins Market Size, Share, and COVID-19 Impact Analysis, By Product Type (Ethylene, Propylene, Butenes, and Others), By End Use (Plastics and Polymers, Automotive, Packaging, Textiles, and Others), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2023 - 2033

Industry: Chemicals & MaterialsGlobal Methanol-to-Olefins Market Insights Forecasts to 2033

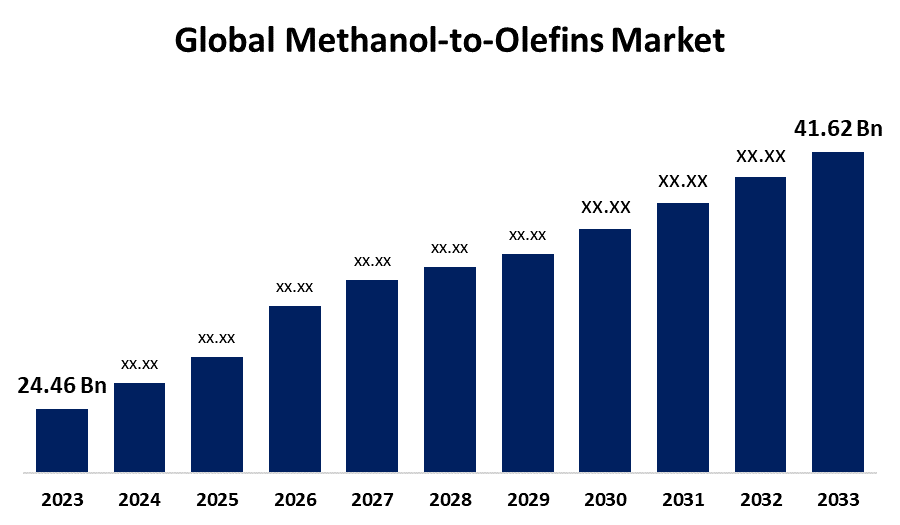

- The Global Methanol-to-Olefins Market Size was Estimated at USD 24.46 Billion in 2023

- The Global Methanol-to-Olefins Market Size is Expected to Grow at a CAGR of around 5.46% from 2023 to 2033

- The Worldwide Methanol-to-Olefins Market Size is Expected to Reach USD 41.62 Billion by 2033

- North America is Expected to Grow the fastest during the forecast period.

Get more details on this report -

The Global Methanol-to-Olefins Market Size is Expected to cross USD 41.62 Billion by 2033, Growing at a CAGR of 5.46% from 2023 to 2033. The emergence of new technologies is anticipated to generate chances for manufacturers to improve current procedures and create innovative applications, ultimately driving growth of the methanol-to-olefins market.

Market Overview

The industry that produces olefins by converting methanol is known as the methanol-to-olefins (MTO) market. The process of converting methanol into valuable olefin compounds, which are essential building blocks for a variety of industries, such as the petrochemical, plastics, and automotive sectors, is commonly known as methanol-to-olefins. The methanol-to-olefins reaction is a significant and fascinating process for both basic science and practical use. The methanol-to-olefins market is driven by the growing demand for olefins, or the fundamental building blocks of plastics, as well as the rising demand for high-performance polymers in the automotive, construction, and packaging industries. Technological developments in process integration and catalyst efficiency are anticipated to propel market expansion. The need for olefins, cost-effectiveness, and improvements in catalytic processes are some of the factors driving the methanol-to-olefins market.

Report Coverage

This research report categorizes the methanol-to-olefins market based on various segments and regions forecasts revenue growth and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the methanol-to-olefins market. Recent market developments and competitive strategies such as expansion, type launch, development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the methanol-to-olefins market.

Methanol-to-Olefins Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2023 |

| Market Size in 2023 : | USD 24.46 Billion |

| Forecast Period: | 2023-2033 |

| Forecast Period CAGR 2023-2033 : | 5.46% |

| 2033 Value Projection: | USD 41.62 Billion |

| Historical Data for: | 2019-2022 |

| No. of Pages: | 214 |

| Tables, Charts & Figures: | 110 |

| Segments covered: | By Product Type, By End Use |

| Companies covered:: | Methanex Corporation, ExxonMobil Chemical, CHINA SHENHUA, Lummus Technology, Royal Dutch Shell, Maverick Synfuels, SABIC Innovative Plastics, Fund Energy Ningbo Co., Ltd., Qatar Petroleum, Reliance Industries Limited, Haldor Topsoe, Linde AG, Gas Chemical Complex, Sinopec Limited, and Others. |

| Pitfalls & Challenges: | Covid-19 Empact, Challenges, Growth, Analysis. |

Get more details on this report -

Driving Factors

The growing need for ethylene and propylene in synthetic materials, plastics, and packaging is driving the growth of the methanol-to-olefins market. The growing need for high-performance, lightweight materials across a range of industries, including consumer products, construction, and the automotive sector, is driving the methanol-to-olefins market. The methanol to olefin industry is expected to continue growing due to good conditions in linked markets, as indicated by its interconnected dependency on the larger petrochemical landscape.

Restraining Factors

High capital expenditure, intricate technological requirements, environmental concerns about emissions, feedstock price instability, and a lack of effective catalysts for large-scale production are some of the restrictions for the methanol-to-olefins market.

Market Segmentation

The methanol-to-olefins market share is classified into product type and end use.

- The propylene segment held the largest share in 2023 and is expected to grow at a significant CAGR during the forecast period.

Based on the product type, the methanol-to-olefins market is divided into ethylene, propylene, butenes, and others. Among these, the propylene segment held the largest share in 2023 and is expected to grow at a significant CAGR during the forecast period. Propylene is preferred in the process due to the particular catalyst design and favorable production conditions. Catalysts such as SAPO-34 are designed to increase the yields of propylene by encouraging the processes resulting from its manufacturing.

- The plastics and polymers segment held the largest share in 2023 and is expected to grow at a significant CAGR during the forecast period.

Based on the end use, the methanol-to-olefins market is divided into plastics and polymers, automotive, packaging, textiles, and others. Among these, the plastics and polymers segment held the largest share in 2023 and is expected to grow at a significant CAGR during the forecast period. The manufacturing of polypropylene and polyethylene in particular. Propylene, a major byproduct of the MTO process, is an essential raw material for the production of polypropylene, a polymer and plastic that finds extensive use in consumer goods, packaging, and automotive components.

Regional Segment Analysis of the Methanol-to-Olefins Market

- North America (U.S., Canada, Mexico)

- Europe (Germany, France, U.K., Italy, Spain, Rest of Europe)

- Asia-Pacific (China, Japan, India, Rest of APAC)

- South America (Brazil and the Rest of South America)

- The Middle East and Africa (UAE, South Africa, Rest of MEA)

Asia Pacific is anticipated to hold the largest share of the methanol-to-olefins market over the predicted timeframe.

Get more details on this report -

Asia Pacific is anticipated to hold the largest share of the methanol-to-olefins market over the predicted timeframe. Asia-Pacific region has a significant industrial base and expanding manufacturing sectors, especially in nations like China and India. The fast expansion of the plastics, automotive, and packaging industries in Asia-Pacific is the primary driver of the strong demand for olefins like propylene and ethylene. China is the primary location for large-scale methanol-to-olefins manufacturing, and methanol-to-olefins facilities are both integrated and freestanding. Coal to Olefins (CTO) operations are a common term used to describe integrated methanol-to-olefins plants.

North America is expected to grow at the fastest CAGR growth of the methanol-to-olefins market during the forecast period. North America's robust petrochemical industries and abundant energy resources make it a dominant force in the market. The need for olefins is driving growth in the well-established petrochemical sector in North America. The demand for olefins, such as ethylene, propylene, and butylene, which are essential building blocks for several industries, including chemicals, plastics, and the automotive sector, is increasing in North America.

Competitive Analysis:

The report offers the appropriate analysis of the key organizations/companies involved within the methanol-to-olefins market along with a comparative evaluation primarily based on their type of offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborative analysis focusing on the current news and developments of the companies, which includes type development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

List of Key Companies

- Methanex Corporation

- ExxonMobil Chemical

- CHINA SHENHUA

- Lummus Technology

- Royal Dutch Shell

- Maverick Synfuels

- SABIC Innovative Plastics

- Fund Energy Ningbo Co., Ltd.

- Qatar Petroleum

- Reliance Industries Limited

- Haldor Topsoe

- Linde AG

- Gas Chemical Complex

- Sinopec Limited

- Others

Key Target Audience

- Market Players

- Investors

- End-users

- Government Authorities

- Consulting And Research Firm

- Venture capitalists

- Value-Added Resellers (VARs)

Recent Development

- In May 2024, The Gas Chemical Complex based on MTO technology (GCC MTO), located in the Karakul Free Economic Zone, was officially launched by Uzbek President Shavkat Mirziyoyev. The complex will serve as the center of the gas chemical cluster by producing 1,100,000 tons of high-quality polymer raw materials annually, including 350,000 tons of polypropylene, 300,000 tons of polyethylene terephthalate, 100,000 tons of ethylene vinyl acetate, 80,000 tons of low-density polyethylene, and 280,000 tons of high-density polyethylene, using cutting-edge MTO technology.

- In February 2021, Neftegaz.RU. The development of a new gas chemical complex based on methanol-to-olefins (MTO) technology in Uzbekistan has advanced significantly, according to Jizzakh Petroleum, an oil and gas business dedicated to growing the country's energy industry.

Market Segment

This study forecasts revenue at global, regional, and country levels from 2023 to 2033. Spherical Insights has segmented the methanol-to-olefins market based on the below-mentioned segments:

Global Methanol-to-Olefins Market, By Product Type

- Ethylene

- Propylene

- Butenes

- Others

Global Methanol-to-Olefins Market, By End Use

- Plastics and Polymers

- Automotive

- Packaging

- Textiles

- Others

Global Methanol-to-Olefins Market, By Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

Frequently Asked Questions (FAQ)

-

1. What is the CAGR of the methanol-to-olefins market over the forecast period?The methanol-to-olefins market is projected to expand at a CAGR of 5.46% during the forecast period.

-

2. What is the market size of the methanol-to-olefins market?The Global Methanol-to-Olefins Market Size is Expected to Grow from USD 24.46 Billion in 2023 to USD 41.62 Billion by 2033, at a CAGR of 5.46% during the forecast period 2023-2033.

-

3. Which region holds the largest share of the methanol-to-olefins market?Asia Pacific is anticipated to hold the largest share of the methanol-to-olefins market over the predicted timeframe.

Need help to buy this report?