Global Motor Lamination Market Size, Share, and COVID-19 Impact Analysis, By Material (Steel, Nickel Alloys, Cobalt Alloys, Others), By Technology (Welding, Bonding, Others), By Vehicle Type (Passenger Car, Light Commercial Vehicles, Truck, Bus), By Application (Performance, Comfort, Safety), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2023 - 2033

Industry: Automotive & TransportationGlobal Motor Lamination Market Insights Forecasts to 2033

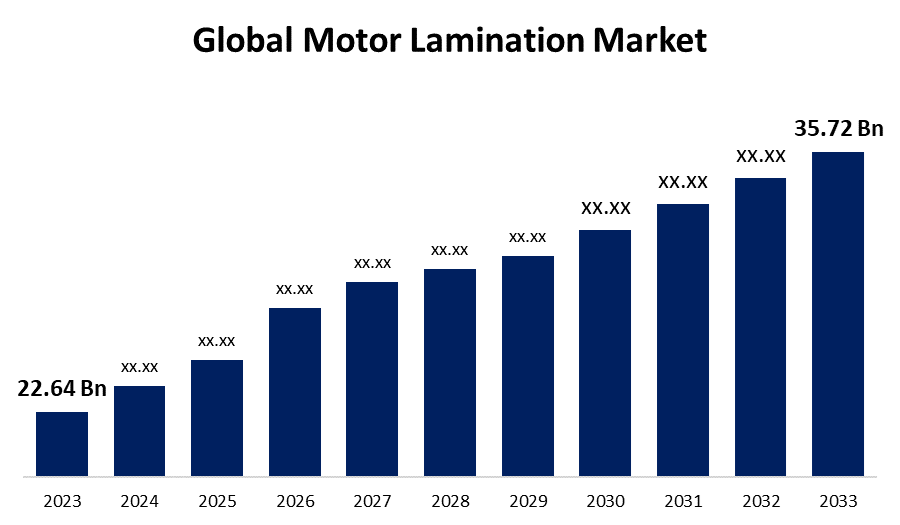

- The Global Motor Lamination Market Size was Valued at USD 22.64 Billion in 2023

- The Market Size is Growing at a CAGR of 4.67% from 2023 to 2033

- The Worldwide Motor Lamination Market Size is Expected to Reach USD 35.72 Billion by 2033

- Europe is Expected to Grow the fastest during the forecast period.

Get more details on this report -

The Global Motor Lamination Market Size is Anticipated to Exceed USD 35.72 Billion by 2033, Growing at a CAGR of 4.67% from 2023 to 2033.

Market Overview

Motor laminations are the internal structures of an electric motor's stator and rotor. They're made of thin metal sheets that are layered, welded, or glued together. They have lower eddy current losses because they are made of discrete pieces of metal rather than monolithic sections. For instance, in June 2023, a team of engineers at MIT was working on constructing a 1 MW motor, which might be a significant step toward electrifying larger aircraft. They methodically built and tested the motor's main components, demonstrating through extensive computations that these components can work together effortlessly to generate one megawatt of electricity. Experimenting with toroidal samples and full-size stator laminations was an important step in confirming the stator core loss estimate. Furthermore, the lamination bonding technique was found to enhance core loss in Fe-Co-V material by a ratio of 1.2. Leading motor lamination companies are developing globally, influencing industry trends. These organizations are embracing technical breakthroughs to improve manufacturing processes and product quality and satisfy the changing needs of global markets. Additionally, strategic collaborations and acquisitions allow them to enter new markets and expand their consumer base. As a result, the motor lamination sector is becoming more globalized, with major companies establishing strong presences in key locations to capitalize on growing possibilities and drive future growth.

Report Coverage

This research report categorizes the market for the global motor lamination market based on various segments and regions forecasts revenue growth and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the global motor lamination market. Recent market developments and competitive strategies such as expansion, product launch, and development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the global motor lamination market.

Motor Lamination Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2023 |

| Market Size in 2023: | USD 22.64 Billion |

| Forecast Period: | 2023 - 2033 |

| Forecast Period CAGR 2023 - 2033 : | 4.67% |

| 2033 Value Projection: | USD 35.72 Billion |

| Historical Data for: | 2019 - 2022 |

| No. of Pages: | 200 |

| Tables, Charts & Figures: | 110 |

| Segments covered: | By Material, By Technology, By Vehicle Type, By Application, By Region |

| Companies covered:: | Tempel, Pitti Engineering Ltd, Alinabal, Inc, EuroGroup Laminations S.p.A., Wingard & Co., Laser Technologies, Lawkim Motors Group, R. Bourgeois, LCS Company, Others, and |

| Pitfalls & Challenges: | COVID-19 Empact, Challenges, Future, Growth, & Analysis |

Get more details on this report -

Driving Factors

The motor lamination market is primarily driven by the growing need for energy-efficient electric motors in a variety of sectors. As governments throughout the world implement tough rules to reduce carbon emissions and promote sustainability, there is a rising emphasis on improving the efficiency of electric motors, which are commonly used in appliances, automotive systems, and industrial gear. Motor laminations improve motor performance and efficiency by reducing energy losses caused by eddy currents and hysteresis. As a result, manufacturers are increasing their investment in sophisticated motor lamination technologies to fulfil the growing need for environmentally friendly and energy-efficient solutions, propelling the motor lamination market forward.

Restraining Factors

The fabrication of motor lamination material demands a significant amount of mechanical energy and force. As a result, it raises the total cost of manufacturing motor lamination materials. Furthermore, any fluctuations in raw material prices harm the worldwide motor lamination market.

Market Segmentation

The global motor lamination market share is classified into material, technology, vehicle type, and application.

- The steel segment is expected to hold the largest share of the global motor lamination market during the forecast period.

Based on the material, the global motor lamination market is categorized into steel, nickel alloys, cobalt alloys, and others. Among these, the steel segment is expected to hold the largest share of the global motor lamination market during the forecast period. Steel, known for its low core loss and magnetic permeability, has become increasingly important in the manufacture of motor laminations. This growth can be attributable to the increasing need for energy-efficient electric motors in a variety of industries. The steel segment's growth is accelerated by a growing emphasis on sustainability and severe energy efficiency rules, which require manufacturers to use materials that improve motor performance. As industries prioritize energy savings and technological improvements, the steel segment will play a critical role in creating the future landscape of the motor lamination market.

- The welding segment is expected to grow at the fastest CAGR during the forecast period.

Based on the technology, the global motor lamination market is categorized into welding, bonding, and others. Among these, the welding segment is expected to grow at the fastest CAGR during the forecast period. Welding is critical in the production of motor laminations because it requires precision and efficiency. The use of novel welding technologies, including laser welding and advanced robotic welding systems, has improved the overall quality and speed of motor lamination manufacturing. These technologies allow for perfect connecting of laminations, resulting in optimal performance and energy efficiency in electric motors. Furthermore, the growing demand for electric vehicles and renewable energy solutions fuels the growth of the motor lamination market, with welding technologies at the forefront of improving manufacturing efficiency and quality. As the industry embraces automation and cutting-edge welding processes, the welding segment is expected to provide a substantial contribution to the motor lamination market's long-term growth and evolution.

- The light commercial vehicles segment is expected to hold a significant share of the global motor lamination market during the forecast period.

Based on the vehicle type, the global motor lamination market is categorized into passenger car, light commercial vehicles, truck, bus. Among these, the light commercial vehicles segment is expected to hold a significant share of the global motor lamination market during the forecast period. As urbanization and e-commerce continue to grow internationally, there is a greater demand for efficient and versatile transportation options, increasing the production and use of light commercial vehicles. These vehicles frequently use complex electric motor systems, in which motor laminations play an important role. Motor laminations are critical components in electric motors, increasing efficiency and performance. With the LCV category expanding rapidly due to economic activity and shifting customer tastes, demand for motor laminations is likely to rise in tandem. This tendency is exacerbated by the increasing emphasis on electric and hybrid vehicles in the LCV category as manufacturers strive to conform to sustainability goals and harsher environmental requirements.

- The comfort segment is predicted to dominate the global motor lamination market during the forecast period.

Based on the application, the global motor lamination market is categorized into performance, comfort, safety. Among these, the comfort segment is predicted to dominate the global motor lamination market during the forecast period. This expansion is especially visible in the automotive industry, where improvements in electric vehicles (EVs) and hybrid vehicles are increasing the demand for efficient and high-performance motor systems. Motor laminations play an important role in boosting electric motor performance by lowering energy losses and increasing overall efficiency. In applications such as power seats, HVAC systems, and electric power steering, the comfort segment is seeing an increase in demand for specialist motor laminations that contribute to smoother and quieter performance, improving the overall driving experience. As consumers value comfort and automakers focus on sustainable and electric transportation solutions, the comfort sector is expected to be a major driver of growth in the motor lamination market.

Regional Segment Analysis of the Global Motor Lamination Market

- North America (U.S., Canada, Mexico)

- Europe (Germany, France, U.K., Italy, Spain, Rest of Europe)

- Asia-Pacific (China, Japan, India, Rest of APAC)

- South America (Brazil and the Rest of South America)

- The Middle East and Africa (UAE, South Africa, Rest of MEA)

Asia Pacific is projected to hold the largest share of the global motor lamination market over the forecast period.

Get more details on this report -

Asia Pacific is projected to hold the largest share of the global motor lamination market over the forecast period. In recent years, Asia Pacific has developed as an automotive production hub. The region's increased car production is primarily due to the government's facilitative regulatory measures, such as 'Make in India'. Countries such as China have emerged as the primary export hubs for car production due to the availability of inexpensive capital, raw materials, and a skilled labor force to meet the demands of other regions. Almost all-important automation and enhancements for performance, safety, and comfort in automobiles are essentially powered by motors, implying that demand for motor lamination will increase in tandem with demand for motors. Given all of this, it is clear that the motor lamination market is anticipated to expand significantly in the forecast period.

Europe is expected to grow at the fastest CAGR growth of the global motor lamination market during the forecast period. The region's automotive sector, in particular, has been a major driver, with the change to electric mobility increasing demand for efficient and high-performance motors. Furthermore, the push for sustainable energy solutions, as well as the ongoing expansion of manufacturing infrastructure in countries such as Germany and the United Kingdom, contribute to the European motor lamination market's rapid growth. As industries expand and prioritize environmentally friendly technology, the need for advanced motor laminations is projected to remain strong, driving further growth in this competitive market sector.

Competitive Analysis:

The report offers the appropriate analysis of the key organizations/companies involved within the global motor lamination market along with a comparative evaluation primarily based on their product offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborative analysis focusing on the current news and developments of the companies, which includes product development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

List of Key Companies

- Tempel

- Pitti Engineering Ltd

- Alinabal, Inc

- EuroGroup Laminations S.p.A.

- Wingard & Co.

- Laser Technologies

- Lawkim Motors Group

- R. Bourgeois

- LCS Company

- Others

Key Market Developments

- In March 2023, EuroGroup Laminations Spa reported an increase in first-quarter revenues of EUR229.8 million compared to EUR191.2 million in the same period previous year. The rise was mostly attributed to the EV and Automotive business, which enjoyed tremendous growth, more than doubling from the same time in 2022, with revenues increasing from EUR55.9 million to EUR116.4 million.

Key Target Audience

- Market Players

- Investors

- End-users

- Government Authorities

- Consulting And Research Firm

- Venture capitalists

- Value-Added Resellers (VARs)

Market Segment

This study forecasts revenue at global, regional, and country levels from 2020 to 2033. Spherical Insights has segmented the global motor lamination market based on the below-mentioned segments:

Global Motor Lamination Market, By Material

- Steel

- Nickel Alloys

- Cobalt Alloys

- Others

Global Motor Lamination Market, By Technology

- Welding

- Bondin

- Others

Global Motor Lamination Market, By Vehicle Type

- Passenger Car

- Light Commercial Vehicles

- Truck

- Bus

Global Motor Lamination Market, By Application

- Performance

- Comfort

- Safety

Global Motor Lamination Market, By Regional

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

Frequently Asked Questions (FAQ)

-

1.What is the CAGR of the global motor lamination market over the forecast period?The Global Motor Lamination Market Size is expected to Grow from USD 22.64 Billion in 2023 to USD 35.72 Billion by 2033, at a CAGR of 4.67% during the forecast period 2023-2033.

-

2.Which region is expected to hold the highest share in the global motor lamination market?Asia Pacific is projected to hold the largest share of the global motor lamination market over the forecast period.

-

3.Who are the top key players in the motor lamination market?Tempel, Pitti Engineering Ltd, Alinabal, Inc, EuroGroup Laminations S.p.A., Wingard & Co., Laser Technologies, Lawkim Motors Group, R. Bourgeois, LCS Company, and others.

Need help to buy this report?