North America Boron Carbide Market Size, Share, and COVID-19 Impact Analysis, By Type (Paste Boron Carbide, Powdered Boron Carbide, Solid Boron Carbide, and Granular Boron Carbide), By Grade (Armor Grade Boron Carbide, Abrasive Grade Boron Carbide, Nuclear Grade Boron Carbide, and Refractory Grade Boron Carbide), By Application (Industrial Manufacturing, Nuclear Power Generation, and Defense and Security Sector), and North America Boron Carbide Market Insights, Industry Trend, Forecasts to 2033

Industry: Chemicals & MaterialsNorth America Boron Carbide Market Insights Forecasts to 2033

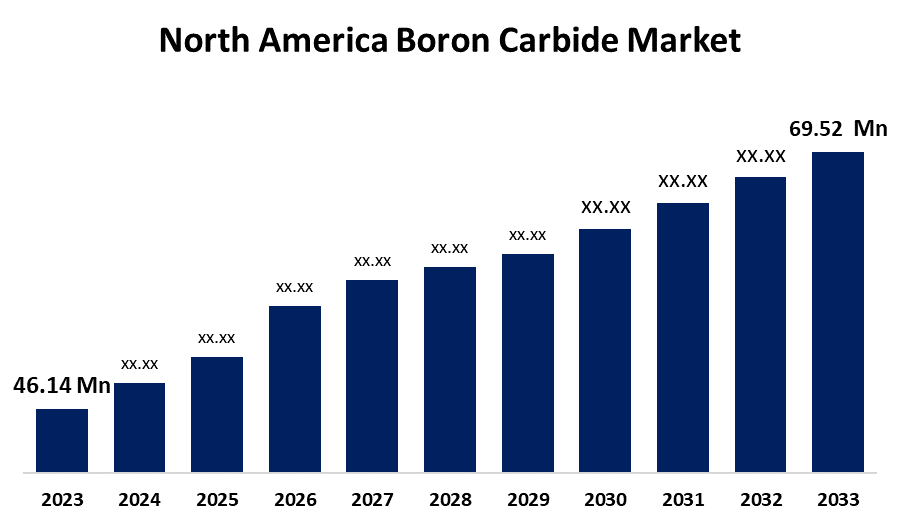

- The North America Boron Carbide Market Size was Valued at USD 46.14 Million in 2023.

- The Market Size is Growing at a CAGR of 4.18% from 2023 to 2033

- The North America Boron Carbide Market Size is Expected to reach USD 69.52 Million by 2033

Get more details on this report -

The North America Boron Carbide Market is Anticipated to Reach USD 69.52 Million by 2033, Growing at a CAGR of 4.18% from 2023 to 2033.

Market Overview

The North America boron carbide market encompasses the production, distribution, and utilization of boron carbide, a ceramic compound with unique properties like high hardness, wear resistance, neutron absorption, and chemical resistance, which is used in defense, nuclear energy, abrasives, and industrial manufacturing. Boron carbide(B4C), also known as black diamond, is a hard ceramic material with a high melting point, outstanding hardness, good mechanical properties, and low specific gravity. It is ideal for lightweight armors and is the third hardest material after diamond and cubic boron nitride. Its high hardness makes it suitable for abrasive powders, lapping, polishing, and water jet cutting of metals and ceramics. Its low specific weight, high hardness, and reasonable toughness make it suitable for body and vehicle armor. Boron carbide is also used as control rods, shielding materials, and neutron detectors in nuclear reactors. As a p-type semiconductor, it can be suitable for high-temperature electronic devices and is an excellent p-type thermoelectric material. Boron carbide is a highly regarded abrasive material with a hardness just below that of diamond, making it a popular choice for lapping agents, finishing semiprecious gems, polishing high-speed steel and carbide-tipped tools, and wire drawing dies. Its sintered shapes are used in sandblasting nozzles and rigid ceramic bearings. In the aerospace industry, it generates a significant amount of heat when combined with oxygen, making it a rocket propellant. In the nuclear industry, it is used as a control and shielding material for neutrons due to its favorable absorption characteristics. The production of boron carbide involves four major steps: reduction of boric acid and carbon mixture in a graphite resistance furnace, communication of as-reduced boron carbide, purification of ground boron carbide powder, and filtering, drying, and classification. The product is generally suitable for the abrasive industry, with a recovery rate of over 85%. Boron carbide is used to create protective tools to resist the impact of sharp objects like bullets, shrapnel, and missiles. Its high toughness makes it difficult for bullets to penetrate, and its surface can shatter into small and hard particles. Boron carbide is also used as a control material in nuclear power plants due to its neutron-absorbing ability, low price, and abundant source. Its high absorption cross-section and lack of radionuclides reduce residual radioactivity levels. B4C ceramic is an ideal shielding material in nuclear industries owing to its heat resistance, no radioisotope production, and low cost. Therefore, these optimistic features of the boron carbide drive the market growth in North America.

Report Coverage

This research report categorizes the North America boron carbide market based on various segments and regions, forecasts revenue growth, and analyzes trends in each submarket. The report analyzes the key growth drivers, opportunities, and challenges influencing the North America boron carbide market. Recent market developments and competitive strategies such as expansion, product launch, and development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyzes their core competencies in each sub-segment of the North America boron carbide market.

North America Boron Carbide Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2023 |

| Market Size in 2023: | USD 46.14 Million |

| Forecast Period: | 2023-2033 |

| Forecast Period CAGR 2023-2033 : | 4.18% |

| 2033 Value Projection: | USD 69.52 Million |

| Historical Data for: | 2019-2022 |

| No. of Pages: | 210 |

| Tables, Charts & Figures: | 120 |

| Segments covered: | By Type, By Grade, By Application and COVID-19 Impact Analysis. |

| Companies covered:: | Washington Mills, Electro Abrasives Corporation, Skyspring Nanomaterials, Reade International Corporation, 3M, Momentive Performance Material, American Elements, Stanford Advanced Materials, San Jose Delta, Advanced Ceramic Materials, and Other Key Vendors. |

| Pitfalls & Challenges: | COVID-19 Empact,Challenges, Future, Growth, & Analysis |

Get more details on this report -

Driving Factors

Boron carbide is a widely used material in the defense industry due to its optimistic properties, such as being lightweight and hard. It is suitable for a variety of industrial applications due to its unique characteristics, which include high hardness, chemical resistance, and abrasion resistance. With defense budgets on the rise and the demand for sophisticated protective solutions growing, boron carbide is anticipated to see a surge in demand. Boron carbide-based materials are being more widely embraced in the fields of metalworking, abrasives, drilling, and wear-resistant components. In the nuclear sector, boron carbide is utilized for its ability to absorb neutrons. Market growth for boron carbide is fueled by ongoing R&D initiatives, and North America enjoys the advantages of a strong R&D environment. This emphasis on refining production methods and boosting performance traits aids in market expansion.

Restraining Factors

The North America boron carbide market faces challenges due to fluctuations in raw material prices, competition from substitute materials like silicon carbide and alumina ceramics, and global economic conditions. These factors can affect manufacturing costs and restrict market growth.

Market Segmentation

The North America boron carbide market share is classified into type, grade, and application.

- The powdered boron carbide segment accounted for the largest market share in 2023 and is expected to grow at a significant CAGR during the forecast period.

The North America boron carbide market is segmented by type into paste boron carbide, powdered boron carbide, solid boron carbide, and granular boron carbide. Among these, the powdered boron carbide segment accounted for the largest market share in 2023 and is expected to grow at a significant CAGR during the forecast period. The segmental expansion is attributed to the superior surface finishing, longer span, lower prices, capability to absorb neutron, lightweight, resistant to chemical reactions, and robust material powder.

- The nuclear grade boron carbide segment held the largest share in 2023 and is predicted to grow at a significant CAGR during the forecast period.

The North America boron carbide market is segmented by grade armor grade boron carbide, abrasive grade boron carbide, nuclear grade boron carbide, and refractory grade boron carbide. Among these, the nuclear grade boron carbide segment held the largest share in 2023 and is predicted to grow at a significant CAGR during the forecast period. The segment growth is ascribed to the regulation of nuclear fission, increasing usage in the energy sector, improved chemical and thermal stability, and use in medical and research facilities.

- The industrial manufacturing segment held a significant share in 2023 and is predicted to grow at a remarkable CAGR during the forecast period.

The North America boron carbide market is segmented by application industrial manufacturing, nuclear power generation, and defense and security sector. Among these, the industrial manufacturing segment held a significant share in 2023 and is predicted to grow at a remarkable CAGR during the forecast period. The sector's growth is facilitated by the growing use of boron carbide in the manufacturing field due to its idealistic characteristics, such as being highly abrasives, regulating nuclear fission, greater wear and tear resistance, and low thermal conductivity.

Competitive Analysis:

The report offers the appropriate analysis of the key organizations/companies involved within the North America boron carbide market, along with a comparative evaluation primarily based on their product offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborative analysis focusing on the current news and developments of the companies, which includes product development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

List of Key Companies

- Washington Mills

- Electro Abrasives Corporation

- Skyspring Nanomaterials

- Reade International Corporation

- 3M

- Momentive Performance Material

- American Elements

- Stanford Advanced Materials

- San Jose Delta

- Advanced Ceramic Materials

- Others

Key Target Audience

- Market Players

- Investors

- End-users

- Government Authorities

- Consulting And Research Firm

- Venture capitalists

- Value-Added Resellers (VARs)

Recent Developments

- In January 2025, Virtual Foundry, a leading innovator in advanced materials for 3D printing, launched the Boron Carbide Filament, a novel product designed for neutron absorption applications. This new filament enables the creation of the 3D printed radiation shielding with unprecedented ease and precision and having scope in nuclear safety, medical imaging, and research.

Market Segment

This study forecasts revenue at North America, regional, and country levels from 2023 to 2033. Spherical Insights has segmented the North America boron carbide market based on the below-mentioned segments:

North America Boron Carbide Market, By Type

- Paste Boron Carbide

- Powdered Boron Carbide

- Solid Boron Carbide

- Granular Boron Carbide

North America Boron Carbide Market, By Grade

- Armor Grade Boron Carbide

- Abrasive Grade Boron Carbide

- Nuclear Grade Boron Carbide

- Refractory Grade Boron Carbide

North America Boron Carbide Market, By Application

- Industrial Manufacturing

- Nuclear Power Generation

- Defense and Security Sector

Need help to buy this report?