North America Metal Injection Molding Market Size, Share, and COVID-19 Impact Analysis, By Material (Stainless Steel, Ferrous Alloys, and Non-Ferrous Alloys), By Component Type (Precision Components, Complex Geometries, and Structural Components), and North America Metal Injection Molding Market Insights, Industry Trend, Forecasts to 2033

Industry: Advanced MaterialsNorth America Metal Injection Molding Market Insights Forecasts to 2033

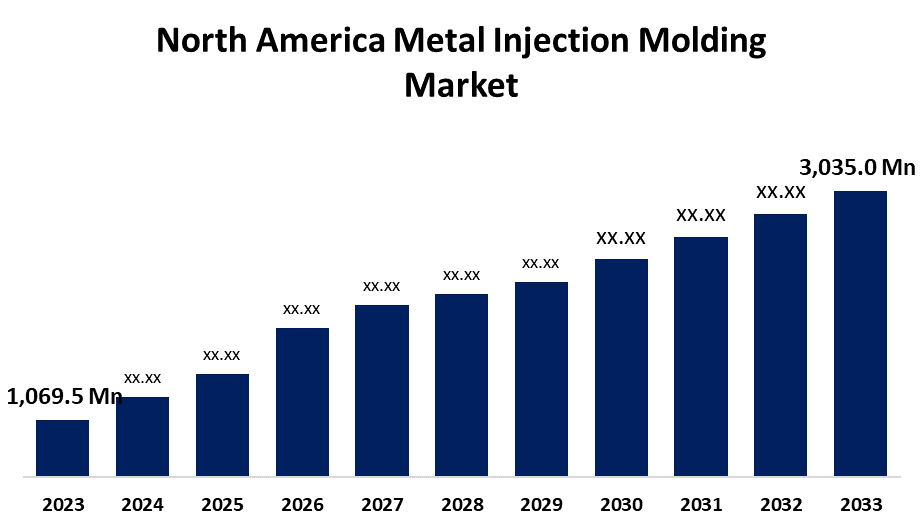

- The North America Metal Injection Molding Market Size was valued at USD 1,069.5 Million in 2023.

- The Market Size is growing at a CAGR of 10.99% from 2023 to 2033

- The North America Metal Injection Molding Market Size is Expected to Reach USD 3,035.0 Million by 2033.

Get more details on this report -

The North America Metal Injection Molding Market Size is Anticipated to Exceed USD 3,035.0 Million by 2033, growing at a CAGR of 10.99% from 2023 to 2033.

Market Overview

The North America metal injection molding (MIM) market refers to the segment of the manufacturing industry that focuses on producing metal parts through a process that combines powder metallurgy and injection molding. This method involves blending metal powders with a binder material, shaping the mixture into desired forms, and then sintering the component to remove the binder and solidify the metal. MIM is widely used for producing complex, high-precision parts in industries such as automotive, aerospace, healthcare, and consumer electronics. The market is driven by the increasing demand for lightweight, durable, and complex metal parts in various industries. The automotive sector, in particular, benefits from MIM technology due to its ability to produce small, intricate components at lower costs compared to traditional manufacturing methods. Advancements in material science, enabling the use of high-performance alloys, and the growing trend of miniaturization in electronic devices further fuel market growth. Additionally, the rising adoption of MIM in the medical and aerospace industries for producing specialized parts contributes to the market’s expansion. Government support for advanced manufacturing technologies, including research and development funding, fosters innovation in the MIM industry. Regulatory frameworks ensuring quality control and environmental sustainability, along with tax incentives for manufacturers adopting green production practices, further encourage market growth. Additionally, the promotion of lightweight materials in the transportation and aerospace sectors aligns with MIM technology, stimulating demand.

Report Coverage

This research report categorizes the market for the North America metal injection molding market based on various segments and regions forecasts revenue growth and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the North America metal injection molding market. Recent market developments and competitive strategies such as expansion, product launch, and development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the North America metal injection molding market.

North America Metal Injection Molding Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2023 |

| Market Size in 2023: | USD 1,069.5 Million |

| Forecast Period: | 2023-2033 |

| Forecast Period CAGR 2023-2033 : | 10.99% |

| 2033 Value Projection: | USD 3,035.0 Million |

| Historical Data for: | 2019-2022 |

| No. of Pages: | 190 |

| Tables, Charts & Figures: | 163 |

| Segments covered: | By Material, By Component Type |

| Companies covered:: | Dynacast, GKN Automotive Limited, Greene Group Industries, Inc. (Britt Manufacturing), Optimim, Dean Group International, Sintex, CMG Technologies, INDO-MIM, Schunk Mobility, Rockleigh Industries, and other key vendors. |

| Pitfalls & Challenges: | COVID-19 Empact, Challenge, Future, Growth, & Analysis |

Get more details on this report -

Driving Factors

The North America metal injection molding (MIM) market is driven by increasing demand for high-precision, lightweight, and complex metal parts in industries such as automotive, aerospace, healthcare, and consumer electronics. MIM's ability to produce intricate components at lower costs compared to traditional manufacturing methods makes it particularly attractive for the automotive sector. Advancements in material science, such as the use of high-performance alloys, and the trend of miniaturization in electronic devices further contribute to market growth. Additionally, the rising adoption of MIM in the medical and aerospace industries for specialized, high-quality parts supports the expansion of the market.

Restraining Factors

The North America metal injection molding (MIM) market faces restraints due to high initial setup costs, limitations in material variety, and challenges in achieving high production volumes. Additionally, competition from alternative manufacturing methods and potential quality control issues may hinder market growth.

Market segmentation

The North America metal injection molding market share is classified into material and component.

- The stainless-steel segment is expected to hold the largest market share through the forecast period.

The North America metal injection molding market is segmented by material into stainless steel, ferrous alloys, and non-ferrous alloys. Among these, the stainless-steel segment is expected to hold the largest market share through the forecast period. This is primarily due to the material's widespread use across various industries, including automotive, aerospace, and healthcare, due to its corrosion resistance, strength, and durability. Stainless steel's versatility in producing complex parts with high precision makes it a preferred choice for MIM applications.

- The precision components segment is expected to hold the largest market share through the forecast period.

The North America metal injection molding market is segmented by component type into precision components, complex geometries, and structural components. Among these, the precision components segment is expected to hold the largest market share through the forecast period. This dominance is driven by the increasing demand for high-precision parts across various industries, including automotive, aerospace, medical devices, and electronics. MIM's ability to produce intricate, high-tolerance components at lower costs compared to traditional manufacturing methods makes it particularly suitable for applications that require complex shapes and tight dimensional control

Competitive Analysis:

The report offers the appropriate analysis of the key organizations/companies involved within the North America metal injection molding market along with a comparative evaluation primarily based on their product offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborative analysis focusing on the current news and developments of the companies, which includes product development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

List of Key Companies

- Dynacast

- GKN Automotive Limited

- Greene Group Industries, Inc. (Britt Manufacturing)

- Optimim

- Dean Group International

- Sintex

- CMG Technologies

- INDO-MIM

- Schunk Mobility

- Rockleigh Industries

- Others

Key Target Audience

- Market Players

- Investors

- End-users

- Government Authorities

- Consulting And Research Firm

- Venture capitalists

- Value-Added Resellers (VARs)

Market Segment

This study forecasts revenue at North America, regional, and country levels from 2020 to 2033. Spherical Insights has segmented the North America metal injection molding market based on the below-mentioned segments:

North America Metal Injection Molding Market, By Material

- Stainless Steel

- Ferrous Alloys

- Non-Ferrous Alloys

North America Metal Injection Molding Market, By Component Type

- Precision Components

- Complex Geometries

- Structural Components

Need help to buy this report?