Global Pipe Coatings Market Size, Share, and COVID-19 Impact, By Product (Liquid, Powder), By Application (Oil And Gas, Marine, Chemical Processing), by Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2022 - 2032.

Industry: Chemicals & MaterialsGlobal Pipe Coatings Market Insights Forecasts to 2032

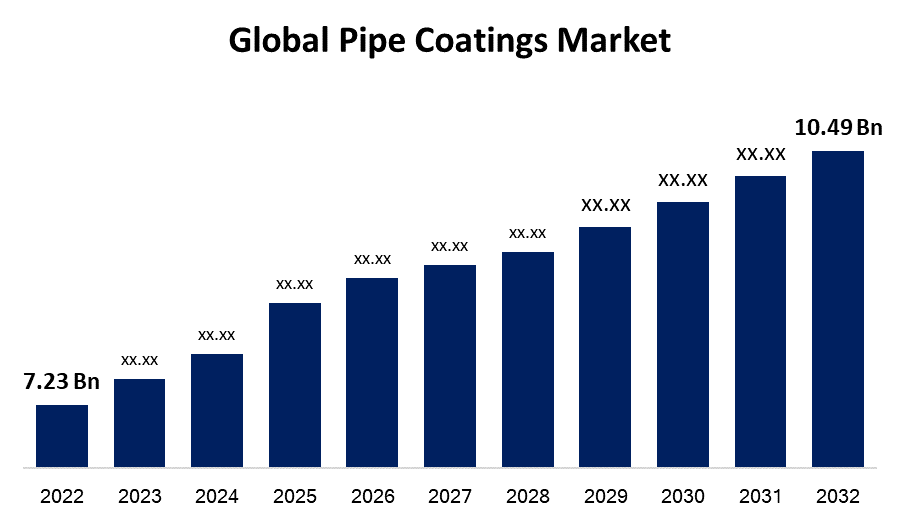

- The Pipe Coatings Market Size was valued at USD 7.23 Billion in 2022.

- The Market Size is Growing at a CAGR of 4.62% from 2022 to 2032

- The Worldwide Pipe Coatings Market Size is expected to reach USD 10.49 Billion by 2032

- North America is expected To Grow the fastest during the forecast period

Get more details on this report -

The Global Pipe Coatings Market Size is expected to reach USD 10.49 Billion by 2032, at a CAGR of 4.62% during the forecast period 2022 to 2032.

Pipe coatings are different compounds that are placed to a pipe's surface to guard against corrosion, abrasion, and other types of damage. Coatings are frequently employed in sectors like infrastructure, water and wastewater treatment, chemical processing, and oil and gas. Fusion-bonded epoxy (FBE), polyethylene (PE), polypropylene (PP), polyurethane (PU), and other corrosion-resistant metals are examples of common pipe coatings. The pipe material, the intended use, and any unique requirements for corrosion protection, temperature tolerance, and chemical resistance all play a role in the coating choice. Pipe coatings serve as a barrier between the pipe surface and corrosive substances in the environment, including moisture, chemicals, and soil. They increase the pipes' lifespan and aid in preventing corrosion.

Impact of COVID 19 On Global Pipe Coatings Market

The worldwide supply chain was hampered by lockdowns, travel restrictions, and temporary closures of manufacturing plants. As a result, there was a lack of the raw materials and parts needed to make pipe coatings, which caused manufacturing to be delayed and cost more money. Due to social segregation policies and governmental constraints, numerous development projects were postponed or delayed. Given that pipes are frequently used in industrial applications, oil and gas pipelines, and infrastructure projects, the fall in building activity had a direct impact on the market for pipe coatings. Due mostly to decreased travel, decreased industrial activity, and an economic slowdown, the pandemic resulted in a major decline in the world's demand for oil and gas. This fall in pipeline developments due to the decline in demand for fossil fuels had an effect on the market for pipe coatings used in the transmission of oil and gas. The pandemic's uncertainty led to market volatility and decreased investment across a range of industries. Demand and price volatility in the pipe coatings market made it difficult for suppliers and manufacturers to foresee and plan successfully.

Global Pipe Coatings Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2022 |

| Market Size in 2022: | USD 7.23 Billion |

| Forecast Period: | 2022-2032 |

| Forecast Period CAGR 2022-2032 : | 4.62% |

| 2032 Value Projection: | USD 10.49 Billion |

| Historical Data for: | 2018-2021 |

| No. of Pages: | 200 |

| Tables, Charts & Figures: | 110 |

| Segments covered: | By Product, By Application, by Region. |

| Companies covered:: | PPG Industries, Inc., Akzo Nobel N.V., The Sherwin-Williams Company, Valspar Industrial., Axalta Coating Systems, LLC, WASCO ENERGY GROUP OF COMPANIES, Arkema Group, 3M, SHAWCOR, Berry Plastics Cpg, Tenaris, Winn & Coales (Denso) Ltd, Aegion Corporation, Dura-Bond Industries, Eupec Pipecoatings France, L.B. Foster Company, Arabian Pipe Coating Company, Perma-Pipe, Inc, Jotun, DuPont. |

| Pitfalls & Challenges: | COVID-19 Empact, Challenge, Future, Growth, & Analysis |

Get more details on this report -

Key Market Drivers

Numerous factors, including rising infrastructure construction, expanding oil and gas exploration, and rising pipeline industry demand for corrosion protection, all have an impact on the growth of the pipe coatings market. The increase of oil and gas exploration and production operations has led to rise in the pipe coatings market. Pipelines are required to carry oil and gas over large distances, both onshore and offshore, due to the demand for energy resources. Pipe coatings are essential for preventing corrosion, which can cause leaks, environmental harm, and expensive maintenance expenses. Pipe coatings are employed in a number of different industries outside the oil and gas one, including water and wastewater, chemicals, and infrastructure. The corrosion resistance, abrasion resistance, and insulating qualities of these coatings increase the pipelines' robustness and longevity. The market for pipe coatings is predicted to keep growing as a result of ongoing infrastructure building initiatives, particularly in developing nations. The demand for pipelines and, consequently, pipe coatings will be driven by rapid urbanisation, population development, and investments in water and wastewater management systems.

Key Market Challenges

Resins, pigments, and additives are frequently used in the production of pipe coatings. The overall production costs and profitability of pipe coating businesses can be greatly impacted by changes in the price of these raw materials. In addition, the construction of infrastructure, including water and gas pipelines, industrial facilities, and water distribution systems, is intimately related to the pipe coatings business. The demand for pipe coatings may be impacted by deteriorating economic conditions or delays in infrastructure projects. Market players must closely watch trends in infrastructure development and modify their strategy as necessary. The usage of eco-friendly coatings and environmental sustainability are becoming more and more important. Strict laws governing emissions, waste disposal, and the use of hazardous materials must be followed by the pipe coatings sector. Making large efforts in research and development to create environmentally friendly coating solutions may be necessary to comply with these laws. The state of the world economy has an impact on the market for pipe coatings. Investments in infrastructure and the demand for pipe coatings may be impacted by economic downturns or changes in particular locations. To reduce the risks brought on by economic volatility, market participants must keep an eye on economic trends and diversify their consumer bases across different geographies.

Market Segmentation

Product Insights

Powder segment is dominating the market with the largest market share over the forecast period

On the basis of product, the global pipe coatings market is segmented into powder and liquid. Among these, the powder segment is dominating the market with the largest market share over the forecast period. When compared to conventional coating techniques, powder pipe coatings offer a more affordable solution. With its high transfer rates and efficiency, the powder coating method minimises material waste. Additionally, the capacity to recycle surplus powder adds to cost savings. Due to their greater corrosion resistance, affordability, environmental advantages, adaptability, improved application procedures, infrastructure expansion, and regulatory compliance, powder pipe coatings have become more popular. The market for powder pipe coatings is projected to keep rising in the future as long as industries continue to place a premium on performance, efficiency, and sustainability.

Application Insights

Oil and gas segment accounted for the largest market share over the forecast period

Based on the application, the global pipe coatings market is segmented into Oil and Gas, Marine, Chemical Processing, Water and Wastewater Treatment, and Others. Among these, the oil and gas segment accounted the largest market share over the forecast period. By shielding pipes from corrosion, abrasion, and other types of damage, pipe coatings are essential to the oil and gas industry. To preserve the integrity and longevity of pipelines, these coatings are applied to both onshore and offshore pipelines. Some pipe coatings are made particularly to improve the fluids being transported's ability to flow. These coatings feature a smooth surface that lessens frictional resistance and reduces pressure drop, improving flow rates and consuming less energy as a result.

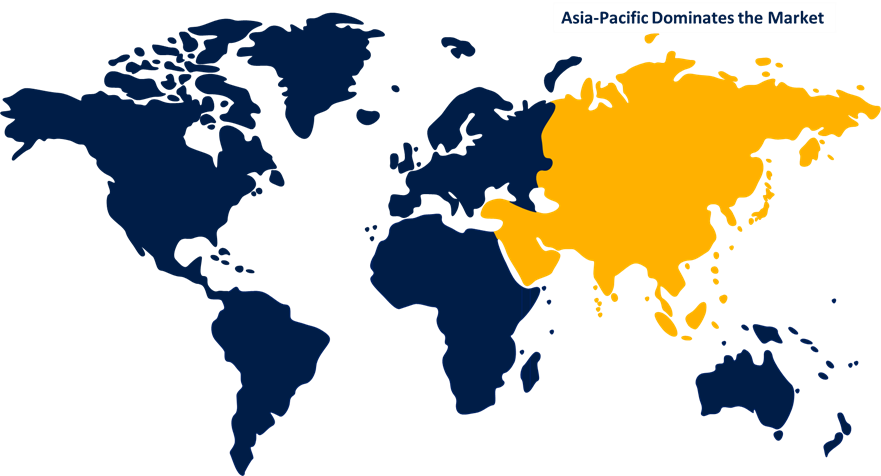

Regional Insights

Asia Pacific region is dominating the market growth over the forecast period

Get more details on this report -

Asia Pacific is dominating the market with the highest market growth over the forecast period. The fast industrialisation, urbanisation, and infrastructural growth occurring in nations like China, India, Japan, South Korea, and Southeast Asian countries are the main factors driving the need for pipe coatings in this region. Oil and gas are heavily consumed in the Asia Pacific area, with China and India playing a big role in this market. In order to ensure the safe and effective transportation of oil and gas products, pipe coatings serve a critical role in the oil and gas sector by preventing pipeline corrosion brought on by harsh working conditions and corrosive substances.

North America, on the other hand, is witnessing the fastest market growth over the forecast period. The pipe coatings market in North America is mostly driven by the oil and gas industry. Shale gas deposits are plentiful in the area, and exploration and production activities have led to a significant increase in the demand for coated pipelines to assure the secure transfer of hydrocarbons. Oil and gas pipelines benefit from coatings' corrosion protection, insulation, and other features, which increase their structural integrity and lifespan.

Recent Market Developments

- The Sherwin-Williams Company said that the acquisition of Sika AG's European industrial coatings business had been completed. The acquired company will be incorporated into the Performance Coatings Group operational segment of Sherwin-Williams.

- The next-generation, ambient-cure PPG HI-TEMP 1027 HD coating was introduced by PPG. It was designed for difficult corrosion-under-insulation (CUI) conditions. When plants are running, it offers great protection against corrosion on pipes, vessels, and structural components.

List of Key Companies

- PPG Industries, Inc.

- Akzo Nobel N.V.

- The Sherwin-Williams Company

- Valspar Industrial.

- Axalta Coating Systems, LLC

- WASCO ENERGY GROUP OF COMPANIES

- Arkema Group

- 3M

- SHAWCOR

- Berry Plastics Cpg

- Tenaris

- Winn & Coales (Denso) Ltd

- Aegion Corporation

- Dura-Bond Industries

- Eupec Pipecoatings France

- L.B. Foster Company

- Arabian Pipe Coating Company

- Perma-Pipe, Inc

- Jotun

- DuPont

Market Segment

This study forecasts revenue at global, regional, and country levels from 2019 to 2032. Spherical Insights has segmented the global Pipe Coatings Market based on the below-mentioned segments:

Pipe Coatings Market, Product Analysis

- Powder

- Liquid

Pipe Coatings Market, Application Analysis

- Oil and Gas

- Marine

- Chemical Processing

- Water and Wastewater Treatment

- Others

Pipe Coatings Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of Middle East & Africa

Frequently Asked Questions (FAQ)

-

1.What is the market size of Pipe Coatings Market?The global Pipe Coatings Market is expected to grow from USD 7.23 Billion in 2022 to USD 10.49 Billion by 2032, at a CAGR of 4.62% during the forecast period 2022-2032.

-

2.Who are the key market players of Pipe Coatings Market?Some of the key market players of PPG Industries, Inc., Akzo Nobel N.V. The Sherwin-Williams Company, Valspar Industrial, Axalta Coating Systems, LLC , WASCO ENERGY GROUP OF COMPANIES, Arkema Group, 3M, SHAWCOR, Berry Plastics Cpg, Tenaris, Winn & Coales (Denso) Ltd, Aegion Corporation, Dura-Bond Industries, Eupec Pipecoatings France, L.B. Foster Company, Arabian Pipe Coating Company, Perma-Pipe, Inc, Jotun, and DuPont.

-

3.Which segment hold the largest market share?Oil and gas segment holds the largest market share is going to continue its dominance.

-

4.Which region is dominating the Pipe Coatings Market?Asia Pacific is dominating the Pipe Coatings Market with the highest market share.

Need help to buy this report?