Global Polyphenylsulfone Market Size, Share, and COVID-19 Impact Analysis, By Form Type (Sheet and Rod), By Application Type (Pipe Fittings and Plumbing, Medical, Automotive, Aerospace, and Baby Bottles), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2023 - 2033.

Industry: Chemicals & MaterialsGlobal Polyphenylsulfone Market Insights Forecasts to 2033

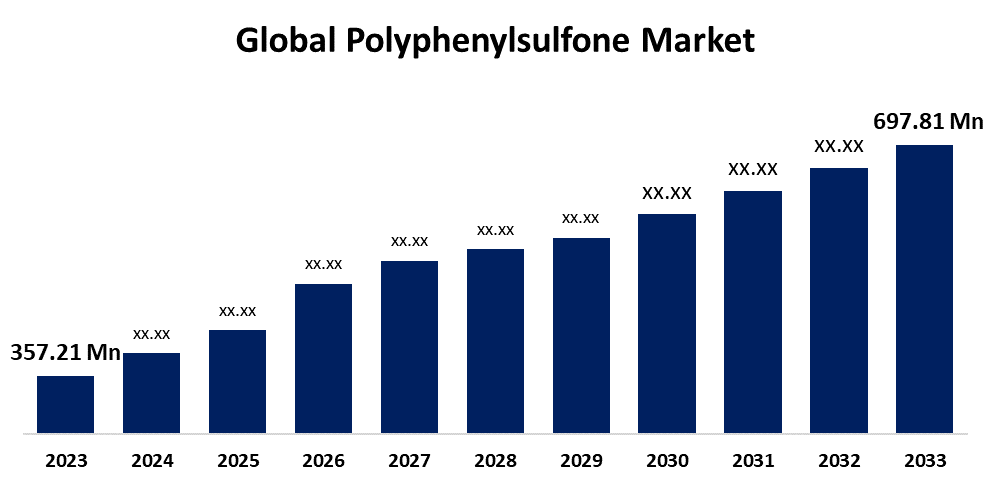

- The Global Polyphenylsulfone Market Size was Valued at USD 357.21 Million in 2023

- The Market Size is Growing at a CAGR of 6.93% from 2023 to 2033

- The Worldwide Polyphenylsulfone Market Size is Expected to reach USD 697.81 Million by 2033

- North America is Expected to Grow the fastest during the forecast period.

Get more details on this report -

The Global Polyphenylsulfone Market Size is Anticipated to Exceed USD 697.81 Million by 2033, Growing at a CAGR of 6.93% from 2023 to 2033.

Market Overview

Polyphenylsulfone is a high-quality thermoplastic that is clear, amorphous, and can withstand high temperatures, produced using difluorodiphenyl sulfone and 4,4-dihydroxybiphenyl. PPSU stands out as the top choice for polysulfone materials. Some of its notable features are its remarkable hardness, flexural and tensile strength, excellent hydrolytic stability, and resistance to chemicals and heat. It has superior mechanical properties compared to PSU and PES, but it is more expensive and thus less frequently used. Polyphenylsulfone is a form of plastic that does not have a distinct structure, leading to low moisture absorption and a high melting point. It consists mainly of aromatic rings linked by sulfone groups. The substance undergoes sterilization through high-temperature steam and can withstand various disinfectants. PPSU has better toughness and heat resistance in comparison to PP and PES. Polyphenylsulfone outperforms regular polysulfone, polyethersulfone, and polyarylsulfone because of its exceptional high-temperature characteristics. Polyphenylsulfone has a glass transition temperature of 288 °C and a heat-deflection temperature of 274 °C. Strong growth in the global market is being driven by its increasing use across different industries. There is a noticeable increase in the market, particularly in the medical and automotive sectors, driven by the growing demand for attributes like thermal stability and resistance to sterilization.

Report Coverage

This research report categorizes the market for the global polyphenylsulfone market based on various segments and regions forecasts revenue growth and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the global polyphenylsulfone market. Recent market developments and competitive strategies such as expansion, product launch, and development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the global polyphenylsulfone market.

Global Polyphenylsulfone Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2023 |

| Market Size in 2023: | USD 357.21 Million |

| Forecast Period: | 2023-2033 |

| Forecast Period CAGR 2023-2033 : | 6.93% |

| 2033 Value Projection: | USD 697.81 Million |

| Historical Data for: | 2019-2022 |

| No. of Pages: | 233 |

| Tables, Charts & Figures: | 110 |

| Segments covered: | By Form Type, By Application Type, By Region |

| Companies covered:: | BASF SE, Solvay Chemical Company, Sumitomo Chemicals, SABIC Innovative plastics, Quadrant Engineering Plastics Product, NYTEF Plastics Ltd., Polymer Dynamix, RTP Company, Westlake Plastics Company, Ensigner Inc., Evonik Industries, Emco Industrial Plastics LLC, Mitsubishi Chemical Corporation, Trident Plastics Inc., and Others |

| Pitfalls & Challenges: | Covid-19 Empact, Challenges, Growth, Analysis. |

Get more details on this report -

Driving Factors

A key factor driving the market is the rising utilization of polyphenylsulfone in the healthcare industry, particularly for manufacturing medical devices. The biocompatibility, sterilizing properties, and chemical resistance of polyphenylsulfone make it perfect for medical device parts like surgical tools, dental equipment, and medical instruments. The increasing need for high-quality materials in the worldwide healthcare sector is a key driver of the PPSU market's expansion. The aerospace sector is also a major consumer of PPSU, utilizing technology for the production of aircraft parts. PPSU's low smoke emission, high heat resistance, and fireproof characteristics make it an ideal choice for a range of aviation uses, such as interior and structural components. Predictions suggest a growth in the polyphenylsulfone industry as demand increases.

Restraining Factors

Unexpected increases in raw material prices might increase production costs and affect the profitability of PPSU manufacturers. Fluctuations in the price of PPSU products might reduce their competitiveness, or this price volatility might reduce consumer appeal. Fluctuations in raw material prices directly affect the profitability of PPSU manufacturers. This price volatility might lead to consumer uncertainty, which might also affect PPSU demand. Rigid regulations can stifle innovation by establishing rigid standards that prevent the adoption of new or complex PPSU formulations.

Market Segmentation

The global polyphenylsulfone market share is classified into form type and application type.

- The sheet segment is expected to grow at the fastest CAGR in the global polyphenylsulfone market during the forecast period.

Based on the form type, the global polyphenylsulfone market is divided into sheets and rods. Among these, the sheet segment is expected to grow at the fastest CAGR in the global polyphenylsulfone market during the forecast period. The segment has grown due to the widespread use of polyphenylsulfone sheets in medical applications such as sterilization of hot trays, dental and surgical tools, and food service trays. The material protects surgical instruments from the harmful effects of microbes and inhibits the spread of fungi that can degrade polymers, boosting industry growth.

The medical segment is expected to hold the largest share of the global polyphenylsulfone market during the forecast period.

Based on the application type, the global polyphenylsulfone market is divided into pipe fittings & plumbing, medical, automotive, aerospace, and baby bottles. Among these, the medical segment is expected to hold the largest share of the global polyphenylsulfone market during the forecast period. A growing aging population with demand for preventive, restorative, and surgical devices for dental care. Due to its strong impact resistance, transparency, design flexibility, remarkable sterilization durability, and resistance to cleaning agents and disinfectants, polyphenylsulfone materials are used in dental and orthopedic devices, which is likely to favor product demand.

Regional Segment Analysis of the Global Polyphenylsulfone Market

- North America (U.S., Canada, Mexico)

- Europe (Germany, France, U.K., Italy, Spain, Rest of Europe)

- Asia-Pacific (China, Japan, India, Rest of APAC)

- South America (Brazil and the Rest of South America)

- The Middle East and Africa (UAE, South Africa, Rest of MEA)

Asia Pacific is anticipated to hold the largest share of the global polyphenylsulfone market over the predicted timeframe.

Get more details on this report -

Asia Pacific is anticipated to hold the largest share of the global polyphenylsulfone market over the predicted timeframe. The market's largest section is found in the Asia Pacific area, which is mostly due to the region's fast industrialization and expansion in important end markets like electronics, medical devices, and automobiles. With their substantial investments in infrastructure and technology, together with their robust manufacturing bases, nations like South Korea, Japan, and China are major contributors. Demand is also greatly increased by the region's developing electronics industry and burgeoning automobile sector. In addition, the presence of emerging economies and the growing emphasis on healthcare innovations are the main drivers propelling the market's growth in this area.

North America is expected to grow at the fastest pace in the global polyphenylsulfone market during the forecast period. The North American market is characterized by advanced technological capabilities and a significant presence of key industries such as aerospace, medical, and automotive. The United States is particularly influential in healthcare and environmental compliance, due to its advanced technology and strict regulations. The sector's emphasis on high-performance materials in the automotive and aerospace sectors, coupled with the increasing adoption of cutting-edge medical technology, also drives demand significantly.

Competitive Analysis:

The report offers the appropriate analysis of the key organizations/companies involved within the global polyphenylsulfone market along with a comparative evaluation primarily based on their product offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborative analysis focusing on the current news and developments of the companies, which includes product development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

List of Key Companies

- BASF SE

- Solvay Chemical Company

- Sumitomo Chemicals

- SABIC Innovative plastics

- Quadrant Engineering Plastics Product

- NYTEF Plastics Ltd.

- Polymer Dynamix

- RTP Company

- Westlake Plastics Company

- Ensigner Inc.

- Evonik Industries

- Emco Industrial Plastics LLC

- Mitsubishi Chemical Corporation

- Trident Plastics Inc.

- Others

Key Target Audience

- Market Players

- Investors

- End-users

- Government Authorities

- Consulting And Research Firm

- Venture capitalists

- Value-Added Resellers (VARs)

Recent Developments

- In November 2023, Solvay and Orbia's Fluorinated Solutions signed a joint venture agreement to establish the largest PVDF (polyvinylidene fluoride) production facility in North America for battery materials.

- In October 2023, BASF SE announced plans to invest a high double-digit million euro amount at its Ludwigshafen location in a new fermentation plant for biology and biotechnology-based crop protection products.

Market Segment

This study forecasts revenue at global, regional, and country levels from 2020 to 2033. Spherical Insights has segmented the global polyphenylsulfone market based on the below-mentioned segments:

Global Polyphenylsulfone Market, By Form Type

- Sheet

- Rod

Global Polyphenylsulfone Market, By Application Type

- Pipe Fittings and Plumbing

- Medical

- Automotive

- Aerospace

- Baby Bottles

Global Polyphenylsulfone Market, Regional

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

Frequently Asked Questions (FAQ)

-

1. Which are the key companies that are currently operating within the market?BASF SE, Solvay Chemical Company, Sumitomo Chemicals, SABIC Innovative Plastics, Quadrant Engineering Plastics Product, NYTEF Plastics Ltd., Polymer Dynamix, RTP Company, Westlake Plastics Company, Ensigner Inc., Evonik Industries, Emco Industrial Plastics LLC, Mitsubishi Chemical Corporation, Trident Plastics Inc., and others.

-

2. What is the size of the global polyphenylsulfone market?The Global Polyphenylsulfone Market is expected to grow from USD 357.21 Million in 2023 to USD 697.81 Million by 2033, at a CAGR of 6.93% during the forecast period 2023-2033.

-

3. Which region is holding the largest share of the market?Asia Pacific is anticipated to hold the largest share of the global polyphenylsulfone market over the predicted timeframe.

Need help to buy this report?