Global PUR-based Reactive Hot Melt Adhesives Market Size, Share, and COVID-19 Impact Analysis, By Substrate (Fiberglass, Nylon, Plastics) By Application (Automotive, Electronics), By Regional (North-America, Europe, Asia-Pacific) Analysis and Forecast till 2022-2030

Industry: Chemicals & MaterialsGlobal PUR-based Reactive Hot Melt Adhesives Market Statistics and Facts Forecasts to 2030

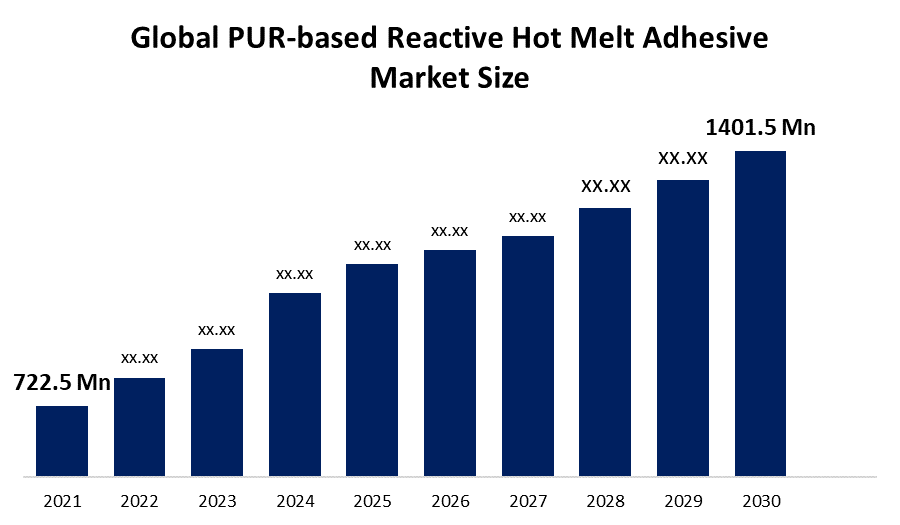

- The Global PUR-based Reactive Hot Melt Adhesives Market Size was valued at USD 722.5 million in 2021.

- The Market is Growing at a CAGR of 7.64% from 2021 to 2030.

- The Worldwide PUR-based Reactive Hot Melt Adhesives Market Size is expected to reach USD 1401.5 million by 2030.

- The North America, Europe, and Asia-Pacific regions make up the majority of the market segments for PUR-based reactive hot melt adhesives.

Get more details on this report -

Market Overview

The Global PUR-based Reactive Hot Melt Adhesives Market Size is said to reach USD 722.5 million in 2021 to USD 1401.5 million in 2030, at a CAGR of 7.64%. One of the top revenue-producing markets in the world is the market for PUR-based reactive hot melt adhesives. The aforementioned market has had considerable growth of about 2% over the past ten years and is expected to reach record-breaking levels of revenue generating between 2021 and 2030.

According to the needs and the industry, such as the automotive and electronics industry, textile industry, paper processing industry, packaging industry, etc., the PUR-based reactive hot melt adhesives find their application in a variety of industries, producing a significant demand for hot melt adhesives.

Due to the affordability and accessibility of such adhesives, the need for hot melt adhesives has increased.

Global PUR-Based Reactive Hot Melt Adhesives Market Drivers -

Wide Range of Applications based on Robust Features of the Hot Melt Adhesives a major driving element for the market

Hot melt adhesives are typically employed in situations where streamlined and simpler manufacturing are required, together with reliable end-product protection. The aforementioned adhesives have several uses in every industrial sector, including those in the automotive, electronics, medical, furniture, and packaging industries. Due to its adaptability with a variety of substrates, including composites, papers, rubbers, plastics, ceramics, metals, glass, and wood, hot-melt adhesives are able to serve such a wide range of applications.

Due to their high melt viscosity and suitability for the applications they are used for, these hot melt adhesives are typically applied using extruding, rolling, or spraying techniques. The hot-melt adhesives serve both B2B and B2C end customers because they may be utilised for both industrial and domestic repair applications. The characteristics of hot-melt adhesives, such as quick setting, temperature resistance, and most crucially, price, make them the most dominant driving force in the industry.

Rising Demand for Light Weight Automotive boosts the market’s growth

At this point in human progress, new inventions and technologies are being developed to improve the comfort and accessibility of human life. One of the industries that is always changing is the automobile. One of the main factors driving the global PUR-based Reactive Hot Melts Adhesives Market at the moment is the demand for lighter, lower carbon-emission automobiles. The goal of the global automotive industry is to create lightweight automobile designs using materials and components that will also serve the needs of environmentally friendly automobiles. This goal is being pursued constantly through innovation.

Adhesives have the ability to join different surfaces with the necessary structural strength and play a significant role in lowering CO2 emissions. These adhesives are well recognised for their effective weight distribution, which leads to higher efficiency, and they make the vehicle lighter, safer, and quieter. Because of this, these adhesives are one of the major factors driving the market for PUR-based reactive hot melt adhesives globally.

Global PUR-based Reactive Hot Melt Adhesives Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2021 |

| Market Size in 2021: | USD 722.5 million |

| Forecast Period: | 2022 - 2030 |

| Forecast Period CAGR 2022 - 2030 : | 7.64% |

| 2030 Value Projection: | USD 1401.5 million |

| Historical Data for: | 2018 - 2021 |

| No. of Pages: | 210 |

| Tables, Charts & Figures: | 123 |

| Segments covered: | By Substrate, By Application, By Regional |

| Companies covered:: | BASF SE, 3M, Henkel, Bostik Inc, H B Fuller, Sika AG, Hunstman International LLC, etc. |

Get more details on this report -

Global PUR-based Reactive Hot Melt Adhesives Market Restraints –

Volatile Raw Material Costs and Dynamic Exchange Rates have an adverse impact on the market’s growth.

Petrochemicals, their derivatives, and tackifiers are the primary raw materials used in the production of hot-melt adhesives. The price of these commodities is based on the price of crude oil on the world market. The price of hot-melt adhesives is influenced by the fluctuating crude oil rates, which also have an impact on the total price structure of the raw materials. The supply and demand concerns and the significant volatility in raw material price structures make it more expensive overall to manufacture hot melt adhesives, which may limit the growth of the PUR-based reactive hot melt adhesive market globally.

Global PUR-based Reactive Hot Melt Adhesives Market Opportunities -

Robust Growth of the Packaging and Labelling Industry creates huge opportunities

Global adhesive market expansion has been significantly boosted by the surge in consumer demand brought on by expanding urbanisation and modern lifestyle trends. Such adhesives have an advantage over others in the labelling sector thanks to capabilities and features like temperature resistance, moisture resistance, and shear resistance. Additionally, the ready-to-eat food culture is expanding rapidly, which fuels the packaging industry. For this use, hot-melt adhesives may be the ideal choice.

Rising Demands for eco-Friendly Adhesives open wide window of opportunities

The use of low-volatile organic chemicals that are safe for the environment and eco-friendly adhesives is seen as a market opportunity for PUR-based reactive hot melt adhesives. The poisonous components in the adhesives create toxic, irritating, and carcinogenic vapours when they dry out, which can have a negative impact on people's health and the quality of the air. Because of this, the production of environmentally friendly adhesives that can do away with the aforementioned concerns is the fundamental goal of the adhesive sector. Due to the rising demand for such environmentally friendly adhesives, the industry is shifting towards an eco-friendly model where consumers are looking for adhesives that won't harm the environment or their health. In light of all of this, eco-friendly adhesives are seen as a business possibility.

Segmental analysis of the global PUR-based reactive hot melt adhesives market

The Global PUR-based reactive hot melt adhesive market is segmented by substrates and by applications.

The fibreglass, nylon, and plastic substrates are further categorised in the global PUR-based reactive hot melt adhesives market. With a market share of USD 304.9 million in 2021 and a projected CAGR of 8.15%, the plastic segment is expected to expand to USD 617.5 million in 2030. Because consumers prefer lightweight and attractive packaging, the demand for packaged food products has increased the need for adhesives in the packaging industry. For this reason, plastic substrates are currently dominating the market segment.

After plastics, fibreglass substrates dominate the market for hot melt glue because they offer outstanding flexibility to the joints at the highest processing speeds and working temperatures. These are primarily used to bind the fibreglass parts that are used in a variety of industries, which brought in an astounding USD 186.80 million for the substrate in 2021 and is anticipated to reach USD 334.85 million in 2030 at a CAGR of 6.7%.

Nylon polymers have a low surface energy and a high moisture absorption rate, making them difficult to bond. Nevertheless, it is utilised in a variety of industrial applications, contributing to sales of USD 50.9 million in 2021 and forecast to reach USD 81.15% million at a CAGR of 5.32%.

Application-based Segmentation –

The automotive and electronics markets are the two segments that the hot melt adhesive market falls under when categorised by applications. With a staggering estimated number of USD 256.86 million in 2030 and a CAGR of 11.95% from USD 93 million in 2021, the automotive segment has the lion's share of the market. Hot melt adhesives are used in cars to make them lightweight and aesthetically pleasing, which is why the automotive sector is driving growth in the adhesive business.

In addition to the automotive industry, there is a significant market for hot melt adhesives in the electronics manufacturing sector. These adhesives are used to build electronic components with maximal adhesive usage for perfect joints throughout the entire structure of the electronic device or piece of equipment. When categorised by applications, it holds the second-largest market share, behind the automotive sector, with estimated revenue of USD 37.06 million in 2030, growing at a CAGR of 8.49 percent. This represents a significant increase from the revenue of USD 17.8 million in 2021.

Regional Analysis

The North America, Europe, and Asia-Pacific regions make up the majority of the market segments for PUR-based reactive hot melt adhesives. With sales projected to reach USD 239.9 million in 2021 and USD 630.30 million in 2022 at a CAGR of 11.35%, Asia-Pacific will continue to be the leading region. The Asia-Pacific area has made the most money thanks to the expanding economies of China and India. India, the rapidly developing automotive centre of South Asia, has the most active automotive manufacturing facilities, which contributes to the region's overall revenue output.

In terms of technological advancement, North America is one of the top regions, and it is also a major producer of PUR-based reactive hot melt adhesives. With a CAGR of 4.07%, the region's revenue grows from USD 142.7 million in 2021 to USD 204.34 million by 2024. The North American area is one of the primary producers for the aforementioned market sector, which helps the region reach the anticipated sales level. Hot melt adhesives are primarily used in the automotive industries.

Given that the automotive manufacturing industry is the centre of the world's automotive industry, Europe offers numerous opportunities for hot melt adhesives. This explains the sector's projected increase from early values of USD 99.40 million in 2021 to USD 189.61 million at a CAGR of 7.44%.

Competitive Analysis –

Following are the major key competitors from the global PUR-based reactive hot melt adhesive industry – BASF SE, 3M, Henkel, Bostik Inc, H B Fuller, Sika AG, Hunstman International LLC, etc.

Recent Developments by Key Players in the industry.

- The Uvinul A-plus production facility in Asia was purchased by BASF SE in December 2021; production is scheduled to begin there in early 2023.

- 3M unveiled a brand-new item in September 2021 dubbed the Next Generation Clear Aligner System to further customise and modernise the designs.

- Henkel Adhesives' Loctite glue products received RecyClass Approval in November 2021 for their potential to be recycled.

- By purchasing Sable Marco Inc, a Canadian maker of cement materials, in March 2022, Sika AG established a new distribution network in Canada.

Global PUR based Reactive Hot Melt Adhesives Market Segmentation

By Substrates –

- Fiberglass

- Nylon

- Plastics

By Applications –

- Automotive

- Electronics

By Region –

- North-America

- Europe

- Asia-Pacific

Need help to buy this report?