Global Rubber Processing Chemicals Market Size, Share, and COVID-19 Impact Analysis, By Type (Antidegradants, Accelerators, Flame Retardants, and Processing Aids), By Application (Tire and Non-Tire), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2023 - 2033.

Industry: Chemicals & MaterialsGlobal Rubber Processing Chemicals Market Insights Forecasts to 2033

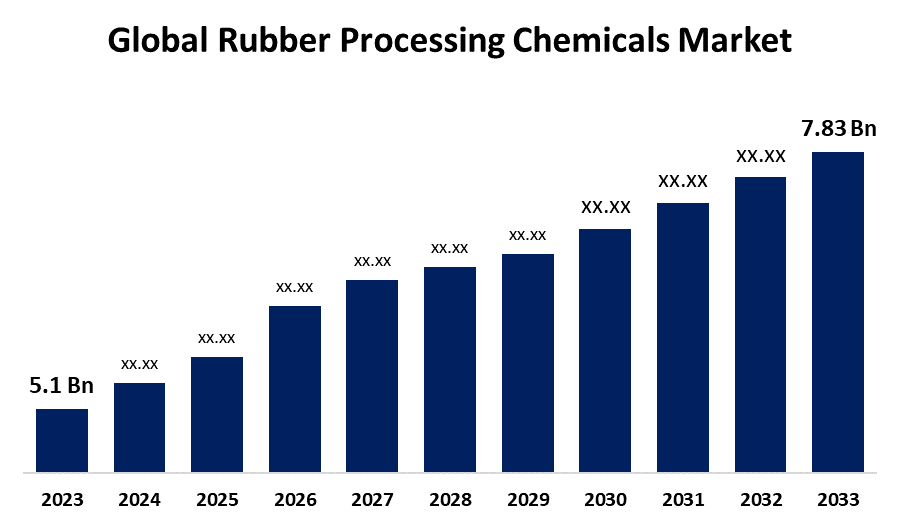

- The Global Rubber Processing Chemicals Market Size Was Valued at USD 5.1 Billion in 2023

- The Market Size is Growing at a CAGR of 4.38% from 2023 to 2033

- The Worldwide Rubber Processing Chemicals Size is Expected to Reach USD 7.83 Billion by 2033

- Europe is expected to Grow the fastest during the forecast period.

Get more details on this report -

The Global Rubber Processing Chemicals Market Size is Anticipated to Exceed USD 7.83 Billion by 2033, Growing at a CAGR of 4.38% from 2023 to 2033.

Market Overview:

Rubber processing chemical is the process of combining vulcanized and unvulcanized latex, coagulating the mixes, and then treating them to enhance their extrusion and scheduling qualities to create a variety of greater rubber products. The rubber products are extensively used in the automotive industry, particularly tires. The rising manufacture and sales of vehicles, particularly in developing nations, are driving the market for chemicals used in rubber processing. Construction of new roads and other structure projects increases the need for rubber-based products like hoses and conveyor belts, which in turn upsurges the demand for chemicals used in the rubber processing industry. The demand for high-performance and specific rubber products in industries like oil and gas, aerospace, and healthcare drives the need for cultured rubber processing chemicals. In addition to being an essential part of rubber compounds, morpholin has several applications in other economic fields. Butylamine is a main aliphatic amine that finds application in the pharmaceutical and agricultural industries as well as in the manufacturing of accelerators for the rubber sector. The use of synthetic and natural rubber elastomers, as well as chemicals used in rubber manufacturing, is expected to rise worldwide which will drive the market growth.

Report Coverage:

This research report categorizes the market for the global rubber processing chemicals market based on various segments and regions forecasts revenue growth and analyses trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the global rubber processing chemicals market. Recent market developments and competitive strategies such as expansion, product launch, and development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the global rubber processing chemicals market.

Global Rubber Processing Chemicals Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2023 |

| Market Size in 2023: | USD 5.1 Billion |

| Forecast Period: | 2023 - 2033 |

| Forecast Period CAGR 2023 - 2033 : | 4.38% |

| 2033 Value Projection: | USD 7.83 Billion |

| Historical Data for: | 2019-2022 |

| No. of Pages: | 220 |

| Tables, Charts & Figures: | 110 |

| Segments covered: | By Type, By Application, By Region |

| Companies covered:: | Merchem Limited, Lanxess, Arkema, Akzo Nobel N.V, Solvay S.A, BASF SE, Linkwell, Arkema SA, Crofa International PlC, NOCIL Ltd., The Chemours Co., Emery Oleochemicals, Henan Xuannuo Imp & Exp Co., Ltd, Vanderbilt Chemicals, LLC, Emerald Performance Materials Company, Eastman Chemical Company, Kumho Petrochemicals, Pukhraj Additives LLP, and Others |

| Pitfalls & Challenges: | COVID-19 Empact, Challenge, Future, Growth, & Analysis |

Get more details on this report -

Driving Factors:

Rubber processing is expected to increase at a rapid rate due to its widespread use in industries such as automotive, electronics, medical, aerospace, and footwear manufacturing. In the upcoming years, the market will also be driven by expanding applications for sound insulation, sealants in construction sites, and roofing materials. The increasing use of synthetic rubber products represents one of the main reasons fuelling the market's expansion. The market has been significantly influenced by technological developments, which have increased productivity, product quality, and sustainability.

Restraining Factors:

Certain rubber processing chemicals can have harmful impacts on the environment and human health when they are produced and used. Hazardous chemical regulations and limits can impede market expansion. Variations in the cost of raw materials can affect producers' profitability and cause pricing volatility in the market.

Market Segmentation:

The global rubber processing chemicals market share is classified into type, application, and end-use.

- The antidegradants segment is expected to have the largest share of the market during the projected timeframe.

Based on the type, the global rubber processing chemicals market is categorized into antidegradants, accelerators, flame retardants, and processing aids. Among these, the antidegradants segment is expected to have the largest share of the market during the projected timeframe. Rubber products require antidegradants, such as antioxidants and antiozonants, to be long-lasting and functional. These compounds shield rubber components from light and oxidation, they are vital to their longevity which is essential for the market growth. These substances are vital and crucial in determining the kind of curing network, as well as factors like scorch safety, reaction speed, bond length, and crosslinking density also driving the market growth. These agents enable the large-scale, economical production of rubber products while hastening the sulfur cross-linking reaction, or vulcanization, and giving rubber products the desired physical qualities.

- The tire segment is anticipated to boost the market growth throughout the forecast period.

Based on the application, the global rubber processing chemicals market is categorized into tire and non-tire. Among these, the tire segment is anticipated to boost the market growth throughout the forecast period. Tire demand is directly increased by the automotive industry's growth, which is fueled by rising car sales and production. This in turn fuels the requirement for rubber processing chemicals to guarantee tire performance and quality. Additionally, leading-edge rubber processing chemicals are desirable for tire technology progressions like the creation of high-performance, fuel-efficient, and all-season tires. To attain the desired qualities, such as augmented grip, sturdiness, and resistance to wear and tear, these compounds are necessary. These are all some of the factors responsible for segment growth during the projected timeframe.

Regional Segment Analysis of the Global Rubber Processing Chemicals Market

- North America (U.S., Canada, Mexico)

- Europe (Germany, France, U.K., Italy, Spain, Rest of Europe)

- Asia-Pacific (China, Japan, India, Rest of APAC)

- South America (Brazil and the Rest of South America)

- The Middle East and Africa (UAE, South Africa, Rest of MEA)

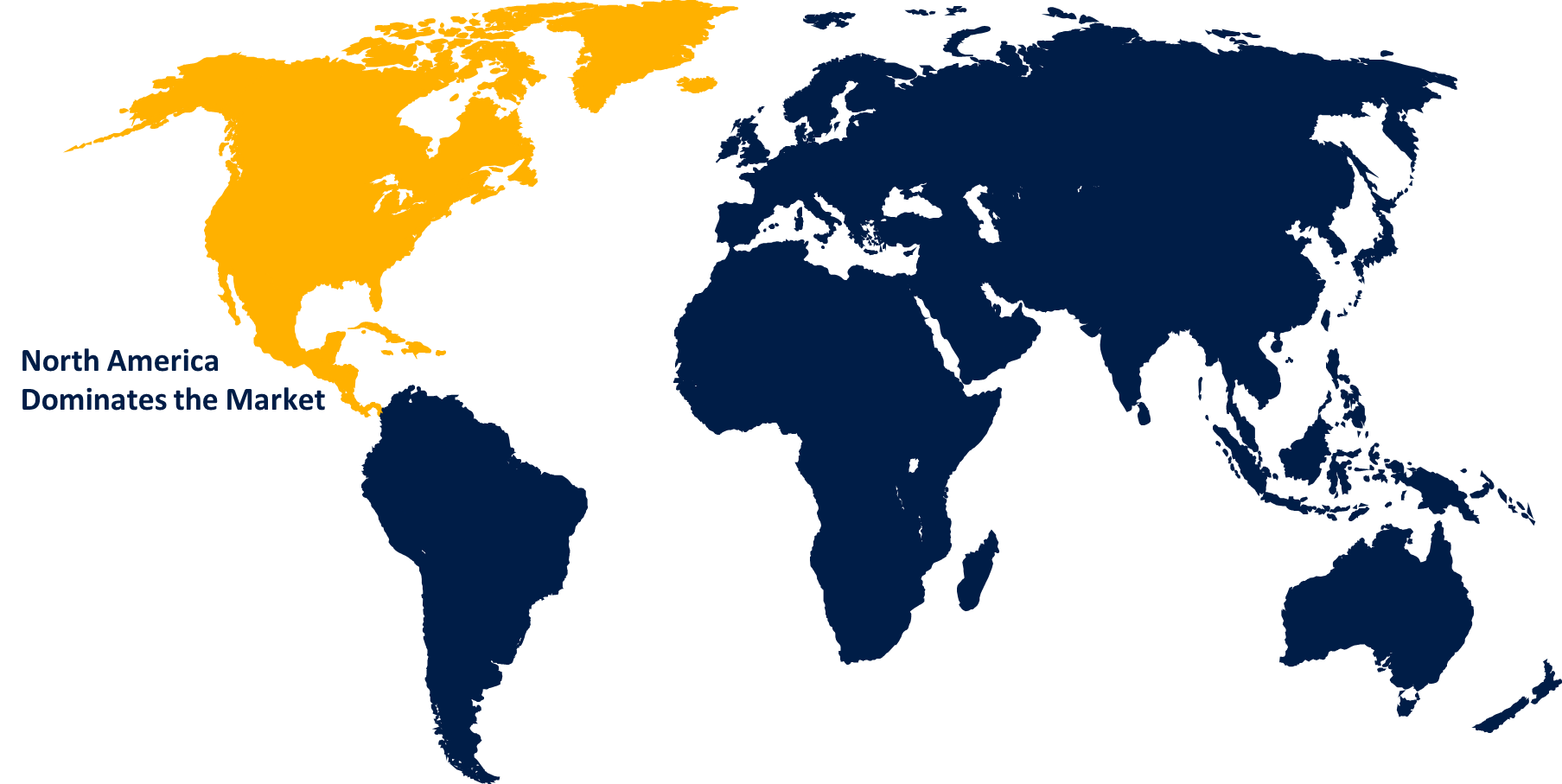

North America is projected to hold the largest share of the global rubber processing chemicals market over the forecast period.

Get more details on this report -

Significant expansion in the rubber processing chemicals business is expected in North America. It can be accredited to the occurrence of sectors that are major manipulators of rubber products, including manufacturing, construction, and the vehicle industry. The region's market is expanding due to the development of the manufacturing, building, and automotive industries. The market is fueled by the growing businesses in North America and the stringent regulations put in place by administrations like the Environmental Protection Agency (EPA) to assurance product acquiescence and security. This has raised the need for premium chemicals that adhere to legal requirements.

Europe region is also expected to fastest CAGR growth during the forecast period. To encourage sustainable manufacturing techniques and lessen the processing European nations have strict laws and standards in place. As a result, safe chemicals with low levels of volatile organic compounds that meet EU regulations have been produced. European manufacturers are devoting resources to research and development to provide novel and environmentally friendly chemicals for rubber production.

Competitive Analysis:

The report offers the appropriate analysis of the key organizations/companies involved within the global rubber processing chemicals market along with a comparative evaluation primarily based on their product offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborative analysis focusing on the current news and developments of the companies, which includes product development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

List of Key Companies

- Merchem Limited

- Lanxess, Arkema

- Akzo Nobel N.V

- Solvay S.A

- BASF SE

- Linkwell

- Arkema SA

- Crofa International PlC

- NOCIL Ltd.

- The Chemours Co.

- Emery Oleochemicals

- Henan Xuannuo Imp & Exp Co., Ltd

- Vanderbilt Chemicals, LLC

- Emerald Performance Materials Company

- Eastman Chemical Company

- Kumho Petrochemicals

- Pukhraj Additives LLP

- Others

Key Market Developments:

- In April 2023, the 360 Tire Recycling Group was acquired by Ecore International, a significant participant in the recycling and conversion of reclaimed goods into performance driver surfaces. them is anticipated that this action increase Ecore International's production scale and give them access to a wide variety of recycled rubber tires.

- In April 2022, 'Eco Point3' is a new mixing technology that Sailun Tire Group introduced. Under liquid phase circumstances, the method would allow rubber-compounding elements to be mixed continuously and uniformly. The technique increases the grip and longevity of tires while providing resistance and efficiency.

Key Target Audience

- Market Players

- Investors

- End-users

- Government Authorities

- Consulting And Research Firm

- Venture capitalists

- Value-Added Resellers (VARs)

Market Segment

This study forecasts revenue at global, regional, and country levels from 2020 to 2033. Spherical Insights has segmented the global rubber processing chemicals market based on the below-mentioned segments:

Global Rubber Processing Chemicals Market, By Type

- Antidegradants

- Accelerators

- Flame Retardants

- Processing Aids

Global Rubber Processing Chemicals Market, By Application

- Tire

- Non-Tire

Global Rubber Processing Chemicals Market, By Regional

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

Frequently Asked Questions (FAQ)

-

1.What is the CAGR of the global rubber processing chemicals market over the forecast period?The global rubber processing chemicals market size is expected to grow from USD 5.1 Billion in 2023 to USD 7.83 Billion by 2033, at a CAGR of 4.38 % during the forecast period 2023-2033.

-

2.Which region is expected to hold the highest share in the global rubber processing chemicals market?North America is projected to hold the largest share of the global rubber processing chemicals market over the forecast period.

-

3.Woare the top key players in the rubber processing chemicals market?Merchem Limited, Lanxess, Arkema, Akzo Nobel N.V, Solvay S.A, BASF SE, Linkwell, Arkema SA, Crofa International PlC, NOCIL ltd, The Chemours Co, Emery Oleochemicals, Henan Xuannuo Imp & Exp Co., Ltd, Vanderbilt Chemicals, LLC, Emerald Performance Materials Company, Eastman Chemical Company, Kumho Petrochemicals, Pukhraj Additives LLP, and Others.

Need help to buy this report?