Singapore Additive Manufacturing Market Size, Share, and COVID-19 Impact Analysis, By Printer Type (Desktop 3D Printer and Industrial 3D Printer), By Technology (Stereolithography, Fuse Deposition Modelling, Selective Laser Sintering, Direct Metal Laser Sintering, Polyjet Printing, Inkjet Printing, Electron Beam Melting, and Others), By Software (Design Software, Inspection Software, Printer Software, and Scanning Software), By Material (Polymer, Metal, and Ceramic), By Application (Prototyping, Tooling, and Functional Parts), and Singapore Additive Manufacturing Market Insights, Industry Trend, Forecasts to 2033

Industry: Chemicals & MaterialsSingapore Additive Manufacturing Market Insights Forecasts to 2033

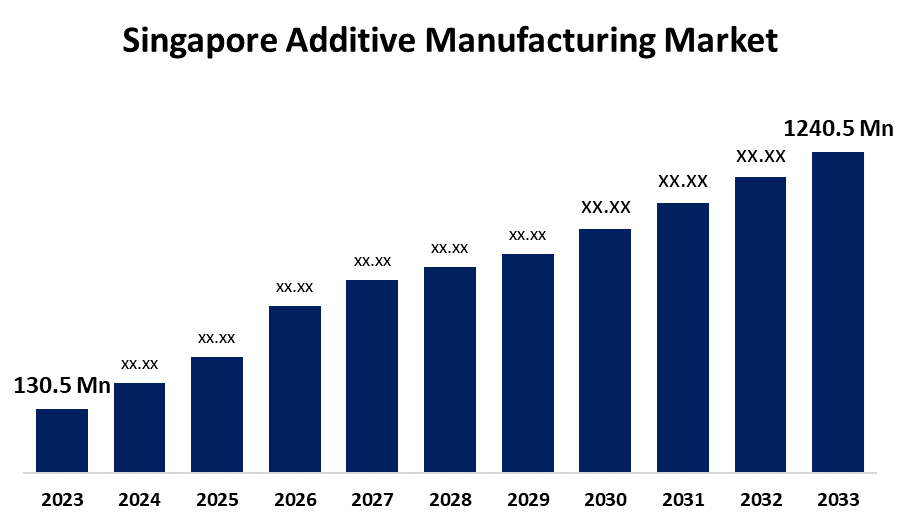

- The Singapore Additive Manufacturing Market Size was valued at USD 130.5 Million in 2023.

- The Market is growing at a CAGR of 25.26% from 2023 to 2033

- The Singapore Additive Manufacturing Market Size is expected to reach USD 1240.5 Million by 2033

Get more details on this report -

The Singapore Additive Manufacturing Market is anticipated to exceed USD 1240.5 Million by 2033, growing at a CAGR of 25.26% from 2023 to 2033. The increasing demand for lightweight components of automotive & aerospace categories and technological advancements in 3D metal printing are driving the growth of the additive manufacturing market in the Singapore.

Market Overview

Additive manufacturing refers to the process of creating an object by building something up, such as molding. This typically uses computer-aided design, or CAD software followed by translation of design into a layer-by-layer framework for additive manufacturing machines. The 3D printer then creates the object immediately. In the automotive and aerospace sectors, where precision in designing and developing parts and complex systems is crucial, this approach is widely used. The increase in the variety of materials available such as high-performance polymers and metals, broadens the scope of application in critical industries like aerospace and medical devices. The integration of AI in additive manufacturing aids in accelerating the processes across various stages of additive manufacturing, which contributes to overall efficiency gains and faster product development cycles, allowing it to fulfill the market demand quickly and stay ahead of the competition.

Report Coverage

This research report categorizes the market for the Singapore additive manufacturing market based on various segments and regions and forecasts revenue growth and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the Singapore additive manufacturing market. Recent market developments and competitive strategies such as expansion, product launch, and development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the Singapore additive manufacturing market.

Driving Factors

Additive manufacturing is used in the aerospace and automotive sectors. The growing aerospace and automotive sector reported to increase in the range of 1-2% annually is contributing to driving the market growth for additive manufacturing. The use of 3D printing and additive manufacturing lowers waste and energy consumption during the manufacturing process, ultimately lowering production costs and promoting the sustainable development of the manufacturing process. The advancement in 3D such as the development of new printing materials including advanced polymers, metals & alloys, and biomaterials for medical applications, profoundly impacting healthcare, aerospace, and architecture industries are bolstering the market growth for additive manufacturing.

Restraining Factors

The high investment required for 3D printing technologies and equipment is restraining the additive manufacturing market. Further, the lack of software efficiency is responsible for hampering the market.

Market Segmentation

The Singapore Additive Manufacturing Market share is classified into printer type, technology, software, material, and application.

- The industrial 3D printer segment is anticipated to hold the largest market share during the forecast period.

The Singapore additive manufacturing market is segmented by printer type into desktop 3D printer and industrial 3D printer. Among these, the industrial 3D printer segment is anticipated to hold the largest market share during the forecast period. Industrial 3D printer is designed and built to live on the factory floor with advanced and enhanced conventional manufacturing features. The rising emphasis on high-volume production by utilizing 3D printing is driving the market growth in the industrial 3D printing segment.

- The stereolithography segment accounted for the largest market share in 2023.

The Singapore additive manufacturing market is segmented by technology into stereolithography, fuse deposition modelling, selective laser sintering, direct metal laser sintering, polyjet printing, inkjet printing, electron beam melting, and others. Among these, the stereolithography segment accounted for the largest market share in 2023. Stereolithography is the most common resin 3D printing process. The increased popularity of stereolithography 3D printing technologies owing to the production of high-resolution and accurate parts for its direct use in rapid prototyping is driving the market.

- The design software segment dominated the market with the largest market share during the forecast period.

Based on the software, the Singapore additive manufacturing market is divided into design software, inspection software, printer software, and scanning software. Among these, the design software segment dominated the market with the largest market share during the forecast period. Design software is utilized for constructing the designs of the object to be printed, especially in the automotive, aerospace & defense, and construction & engineering industries.

- The metal segment is expected to grow at the fastest CAGR growth over the forecast period.

Based on the material, the Singapore additive manufacturing market is divided into polymer, metal, and ceramic. Among these, the metal segment is expected to grow at the fastest CAGR growth over the forecast period. The 3D metal objects are often manufactured by layering fine metal powders layer-by-layer by using bonding agents in between layers. The rising need from the automotive industry for additive manufacturing is propelling the market demand.

- The prototyping segment dominated the market with the largest revenue share in 2023.

Based on the application, the Singapore additive manufacturing market is divided into prototyping, tooling, and functional parts. Among these, the prototyping segment dominated the market with the largest revenue share in 2023. Additive manufacturing techniques provide the possibility for rapid prototyping with complex geometries. For instance, stereolithography and fused deposition modeling enable quick prototype development. The extensive application of the prototyping process in several industries is driving the market.

Competitive Analysis:

The report offers the appropriate analysis of the key organizations/companies involved within the Singapore additive manufacturing market along with a comparative evaluation primarily based on their product offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborative analysis focusing on the current news and developments of the companies, which includes product development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

List of Key Companies

- SLM Solutions

- Proto Labs

- Renishaw plc.

- YAMAZAKI MAZAK CORPORATION

- Ultimaker BV

- Optomec, Inc.

- Markforged

- Stratasys

- ExOne

- Others

Key Target Audience

- Market Players

- Investors

- End-users

- Government Authorities

- Consulting And Research Firm

- Venture capitalists

- Value-Added Resellers (VARs)

Recent Developments

- In August 2024, Class Society ABS is leading a project in Singapore to accelerate the adoption of additive manufacturing (AM, aka 3D printing) within the maritime sector.

- In July 2024, ABS and the Maritime and Port Authority of Singapore (MPA) are collaborating to create a model-based additive manufacturing (AM) qualification framework tailored for the maritime industry.

Market Segment

This study forecasts revenue at Singapore, regional, and country levels from 2020 to 2033. Spherical Insights has segmented the Singapore Additive Manufacturing Market based on the below-mentioned segments:

Singapore Additive Manufacturing Market, By Printer Type

- Desktop 3D Printer

- Industrial 3D Printer

Singapore Additive Manufacturing Market, By Technology

- Stereolithography

- Fuse Deposition Modelling

- Selective Laser Sintering

- Direct Metal Laser Sintering

- Polyjet Printing

- Inkjet Printing

- Electron Beam Melting

- Others

Singapore Additive Manufacturing Market, By Software

- Design Software

- Inspection Software

- Printer Software

- Scanning Software

Singapore Additive Manufacturing Market, By Material

- Polymer

- Metal

- Ceramic

Singapore Additive Manufacturing Market, By Application

- Prototyping

- Tooling

- Functional Parts

Need help to buy this report?