South Korea Automotive Parts Zinc Die Casting Market Size, Share, and COVID-19 Impact Analysis, By Production Process (Pressure Die Casting, Vacuum Die Casting, Squeeze Die Casting, and Semi-Solid Die Casting), By Application (Body Assembly, Engine Parts, Transmission Parts, and Others), and South Korea Automotive Parts Zinc Die Casting Market Insights Forecasts to 2033

Industry: Automotive & TransportationSouth Korea Automotive Parts Zinc Die Casting Market Insights Forecasts to 2033

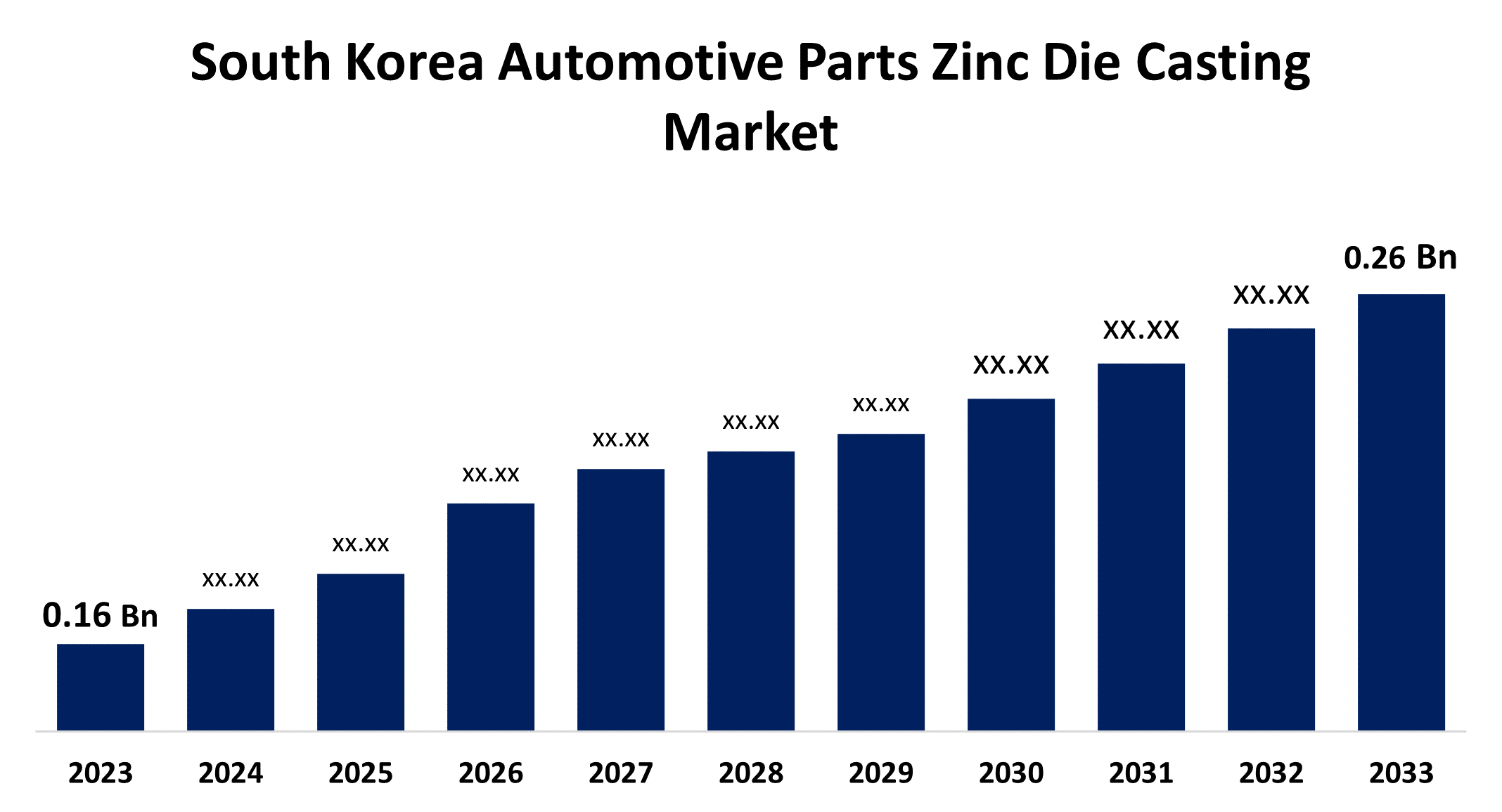

- The South Korea Automotive Parts Zinc Die Casting Market Size was valued at USD 0.16 Billion in 2023.

- The Market Size is Growing at a CAGR of 4.97% from 2023 to 2033

- The South Korea Automotive Parts Zinc Die Casting Market Size is Expected to Reach USD 0.26 Billion by 2033

Get more details on this report -

The South Korea Automotive Parts Zinc Die Casting Market is Anticipated to Exceed USD 0.26 Billion by 2033, growing at a CAGR of 4.97% from 2023 to 2033.

Market Overview

The automotive parts zinc die casting involves the accurate and effective production of car parts through zinc die casting. This technique enables the creation of detailed designs and lightweight components, which are essential for improving the fuel efficiency and performance of vehicles. The market growth is driven by the country's growing automotive manufacturing industry, increasing need for lightweight and sturdy components, strict rules on emissions and fuel efficiency, cost efficiency of zinc die casting, presence of skilled workers, and the emergence of electric vehicles. Technological advances and the increasing demand for high-pressure die-casting are driving the growth of the zinc die-casting machines market. Recent advancements and innovations have transformed automotive parts due to the evolution of new technologies. Auto components made from lightweight materials gained significant attention among them. In comparison to other die-casting components, zinc die-casting components generally have superior mechanical characteristics, such as toughness, as well as providing improved surface finish and reduced thermal shock during casting because of their lower operating temperature. The market sees potential in the rising sales of electric vehicles, leading to a need for more lightweight components. Big companies such as Dynacast are dedicated to finding inexpensive raw materials and alloys that provide enhanced longevity.

Report Coverage

This research report categorizes the market for South Korea automotive parts zinc die casting market based on various segments and regions and forecasts revenue growth and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the South Korea automotive parts zinc die-casting market. Recent market developments and competitive strategies such as expansion, product launch, and development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segments of the South Korea automotive parts zinc die casting market.

South Korea Automotive Parts Zinc Die Casting Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2023 |

| Market Size in 2023 : | USD 0.16 Billion |

| Forecast Period: | 2023-2033 |

| Forecast Period CAGR 2023-2033 : | 4.97% |

| 2033 Value Projection: | USD 0.26 Billion |

| Historical Data for: | 2019-2022 |

| No. of Pages: | 200 |

| Tables, Charts & Figures: | 110 |

| Segments covered: | By Production Process, By Application |

| Companies covered:: | Ashok Minda Group, Brill cast Manufacturing LLC, Dynacast, Pace Industries, Sandhar Technologies Ltd, and Others Key Vendors. |

| Pitfalls & Challenges: | COVID-19 Empact, Challenges, Future, Growth, & Analysis |

Get more details on this report -

Driving Factors

The major driving force is the demand for lightweight automotive parts, so as to improve fuel efficiency and comply with stringent environmental regulations. Flexibility and complexity of zinc die casting to create intricate and complex designs in automotive components, meeting modern design requirements. Key factors driving the South Korea automotive parts zinc die casting market include the country's rapidly expanding automotive industry. This is due to the growing trend of electric vehicles (EVs) along with a focus on quality and precision in manufacturing processes, which drive the growth of the market. Other aspects like the country's skilled labor force along with advanced technology infrastructure assist in a conducive environment for market growth across the country.

Restraining Factors

The possible issue of changing zinc prices impacts the total production cost and market competitiveness.

Market Segment

The South Korea automotive parts zinc die casting market share is classified into production process and application.

- The pressure die casting segment is expected to hold the largest market share through the forecast period.

The South Korea automotive parts zinc die casting market is segmented by production process into pressure die casting, vacuum die casting, squeeze die casting, and semi-solid die casting. Among these, the pressure die-casting segment is expected to hold the largest market share through the forecast period. This process is suited to high-volume production, high-precision production of complex shapes, and efficiency thus, it is particularly well-suited for the automotive industry. The demand for light as well as durable vehicle components can be said to be further enhancing the dominance of pressure die casting in this market.

- The engine parts segment is expected to hold the largest market share through the forecast period.

The South Korea automotive parts zinc die casting market is segmented by application into body assembly, engine parts, transmission parts, and others. Among these, the engine parts segment is expected to hold the largest market share through the forecast period. This is mainly because the market is demanding lightweight, hard, and high-performance components that zinc die casting can offer. Engine parts require a great deal of precise engineering and durability, which means they support the advantages of zinc die casting well, making this a prime focus area for manufacturers in the automotive sector.

Competitive Analysis:

The report offers the appropriate analysis of the key organizations/companies involved within the South Korea automotive parts zinc die casting market along with a comparative evaluation primarily based on their product offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborative analysis focusing on the current news and developments of the companies, which includes product development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

List of Key Companies

- Ashok Minda Group

- Brill cast Manufacturing LLC

- Dynacast

- Pace Industries

- Sandhar Technologies Ltd

- Others

Key Target Audience

- Market Players

- Investors

- End-users

- Government Authorities

- Consulting and Research Firm

- Venture capitalists

- Value-Added Resellers (VARs)

Recent Development

- In August 2023, Hyundai Motor Group agreed to partner with Korea Zinc, wherein it bought a 5% stake in the metal smelting firm. The two also collaborate on sourcing and processing raw materials.

Market Segment

This study forecasts revenue at regional, and country levels from 2022 to 2033. Spherical Insights has segmented the South Korea automotive parts zinc die casting market based on the below-mentioned segments

South Korea Automotive Parts Zinc Die Casting Market, By Production Process

- Pressure Die Casting

- Vacuum Die Casting

- Squeeze Die Casting

- Semi-Solid Die Casting

South Korea Automotive Parts Zinc Die Casting Market, By Application

- Body Assembly

- Engine Parts

- Transmission Parts

- Others

Need help to buy this report?