Global Surface Inspection Market Size, Share, and COVID-19 Impact Analysis, By Component (Cameras, Frame Grabbers, Optics, Lighting Equipment, Processors, Software, and Others), By Surface Type (2D and 3D), By System (Computer-based Systems and Camera-based Systems), By Deployment (Traditional and Robotic Cell), By Industry Vertical (Semiconductors, Automotive, Electrical & Electronics, Food & Packaging, Pharmaceutical, and Others), By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2022 – 2032

Industry: Semiconductors & ElectronicsGlobal Surface Inspection Market Insights Forecasts to 2032

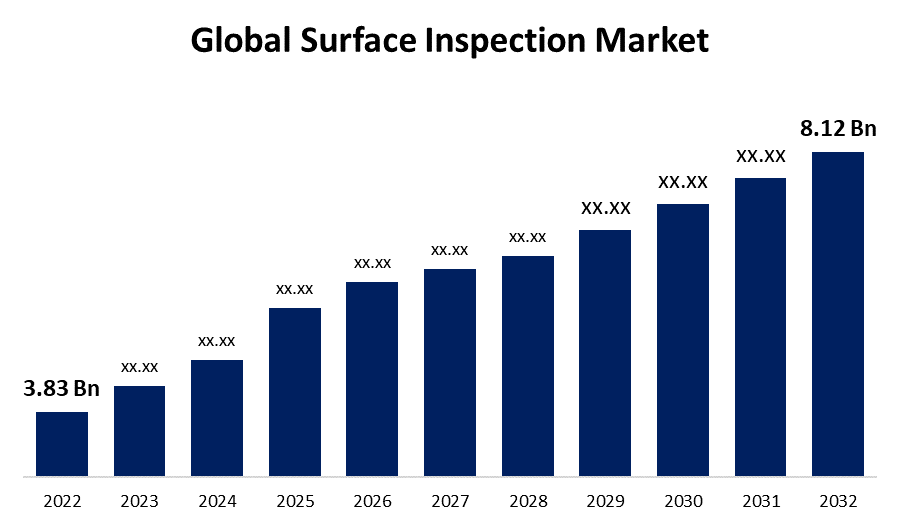

- The Global Surface Inspection Market Size was valued at USD 3.83 Billion in 2022.

- The Market Size is Growing at a CAGR of 7.8% from 2022 to 2032

- The Worldwide Surface Inspection Market Size is expected to reach USD 8.12 Billion by 2032

- Asia-Pacific is expected to highest grow during the forecast period

Get more details on this report -

The Global Surface Inspection Market Size is expected to reach USD 8.12 Billion by 2032, at a CAGR of 7.8% during the forecast period 2022 to 2032.

Market Overview

Surface inspection is a crucial process used in manufacturing and quality control to ensure the integrity and reliability of products. It involves the examination of the outer surface of an object to detect defects, irregularities, or imperfections that may affect its functionality or appearance. Surface inspection techniques vary depending on the type of material and the desired level of scrutiny. Common methods include visual inspection, automated imaging systems, and advanced technologies such as machine vision and artificial intelligence. These approaches enable rapid and accurate identification of flaws such as scratches, dents, cracks, or color variations. By detecting and addressing surface defects early on, surface inspection helps maintain product quality, reduce waste, enhance customer satisfaction, and uphold industry standards.

Report Coverage

This research report categorizes the market for surface inspection market based on various segments and regions and forecasts revenue growth and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the surface inspection market. Recent market developments and competitive strategies such as expansion, product launch, and development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segments of the surface inspection market.

Global Surface Inspection Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2022 |

| Market Size in 2022 : | USD 3.83 Billion |

| Forecast Period: | 2022-2032 |

| Forecast Period CAGR 2022-2032 : | 7.8% |

| 2032 Value Projection: | USD 8.12 Billion |

| Historical Data for: | 2018-2021 |

| No. of Pages: | 200 |

| Tables, Charts & Figures: | 125 |

| Segments covered: | By Component, By Surface Type, By System, By Deployment, By Industry Vertical, By Region |

| Companies covered:: | Isra Vision, Ametek Inc., Matrox Imaging, Datalogic S.P.A., Teledyne Technologies, Keyence Corporation, Cognex Corporation, OMRON Corporation, Basler AG, Baumer Holding AG, Panasonic Corporation, National Instruments Corporation, Pixargus, Dark Field Technologies, Stemmer Imaging, Maschinenfabrik Herkules GmbH & Co. KG |

| Pitfalls & Challenges: | COVID-19 Empact,Challenges, Future, Growth, & Analysis |

Get more details on this report -

Driving Factors

The surface inspection market is driven by several factors that contribute to its growth and adoption across industries due to increasing demand for quality control and assurance in manufacturing processes fuels the need for reliable surface inspection solutions. Additionally, stringent government regulations and quality standards imposed on industries like automotive, electronics, and pharmaceuticals drive the implementation of surface inspection systems. The advancements in imaging technologies, such as machine vision and artificial intelligence, play a significant role in enhancing inspection accuracy and efficiency. Moreover, the rising focus on reducing production costs, minimizing waste, and improving productivity encourages companies to invest in surface inspection solutions to detect and address surface defects early on. Furthermore, the growing adoption of automation in manufacturing processes and the expanding use of surface inspection in emerging sectors like aerospace and energy further contribute to the market's expansion.

Restraining Factors

While the surface inspection market has numerous drivers, it also faces certain restraints. One of the key challenges is the high initial cost associated with implementing surface inspection systems, including the hardware, software, and training required. Additionally, the complexity and customization required for different manufacturing processes pose a barrier to widespread adoption. Limited awareness and understanding of surface inspection technologies among manufacturers, particularly in small and medium-sized enterprises, can also hinder market growth. Furthermore, the integration of surface inspection systems into existing production lines and workflows can be a time-consuming and disruptive process. Overall, the potential limitations in accurately detecting certain types of defects or variations on complex surfaces can impact the effectiveness of surface inspection solutions.

Market Segmentation

- In 2022, the 2D surface inspection segment accounted for more than 57.3% market share

On the basis of the surface type, the global surface inspection market is segmented into 2D and 3D. The surface inspection market, the 2D surface inspection segment has emerged as the leader, holding the largest market share. This can be attributed to several factors because 2D surface inspection technologies offer a cost-effective and efficient solution for detecting defects and irregularities on the surface of objects. They utilize high-resolution cameras and image processing algorithms to analyze 2D images and identify flaws such as scratches, dents, and color variations. Additionally, 2D surface inspection is widely applicable across various industries, including automotive, electronics, packaging, and pharmaceuticals, where product quality and visual appearance are critical. Moreover, advancements in machine vision and image processing techniques have improved the accuracy and speed of 2D surface inspection systems, further driving their adoption. Furthermore, the simplicity and ease of integration of 2D inspection technologies into existing production lines have contributed to their widespread use and dominance in the market.

- In 2022, the semiconductor industry segment dominated with around 34.2% market share

Based on the industry vertical, the global surface inspection market is segmented into semiconductors, automotive, electrical & electronics, food & packaging, pharmaceutical, and others. The semiconductor industry has emerged as a dominant player in the global market, holding the largest market share. Several factors contribute to its significant presence because semiconductors are essential components in a wide range of electronic devices, including smartphones, computers, automotive electronics, and industrial equipment. The increasing demand for these devices drives the demand for semiconductors. Additionally, technological advancements such as the Internet of Things (IoT), artificial intelligence (AI), and 5G networks further fuel the demand for semiconductors. Furthermore, the rapid growth of industries like automotive, healthcare, and consumer electronics in emerging economies like China, India, and Southeast Asia has significantly contributed to the expansion of the semiconductor market. Moreover, the continuous investments in research and development by key industry players, coupled with the need for miniaturization and enhanced performance of electronic devices, have further propelled the growth and market share of the semiconductor industry.

Regional Segment Analysis of the Surface Inspection Market

- North America (U.S., Canada, Mexico)

- Europe (Germany, France, U.K., Italy, Spain, Rest of Europe)

- Asia-Pacific (China, Japan, India, Rest of APAC)

- South America (Brazil and the Rest of South America)

- The Middle East and Africa (UAE, South Africa, Rest of MEA)

Asia-Pacific held the largest market with more than 37.8% revenue share in 2022.

Get more details on this report -

Based on region, the Asia-Pacific region currently holds the largest market share in the surface inspection market. This can be attributed to several factors due to the region is home for some of the world's largest manufacturing economies, including China, Japan, and South Korea. These countries have a strong presence in industries such as automotive, electronics, and semiconductor manufacturing, which require extensive surface inspection processes. Additionally, the rapid industrialization and urbanization in emerging economies like India, Indonesia, and Vietnam have led to increased manufacturing activities and the demand for quality control solutions. Furthermore, the availability of a large skilled workforce, advancements in technology, and government initiatives promoting industrial automation and quality assurance have also contributed to the dominance of the Asia-Pacific region in the surface inspection market.

Competitive Analysis:

The report offers the appropriate analysis of the key organizations/companies involved within the global surface inspection market along with a comparative evaluation primarily based on their product offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborative analysis focusing on the current news and developments of the companies, which includes product development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

List of Companies:

- Isra Vision

- Ametek Inc.

- Matrox Imaging

- Datalogic S.P.A.

- Teledyne Technologies

- Keyence Corporation

- Cognex Corporation

- OMRON Corporation

- Basler AG

- Baumer Holding AG

- Panasonic Corporation

- National Instruments Corporation

- Pixargus, Dark Field Technologies

- Stemmer Imaging

- Maschinenfabrik Herkules GmbH & Co. KG.

Key Target Audience

- Market Players

- Investors

- End-Users

- Government Authorities

- Consulting and Research Firm

- Venture Capitalists

- Value-Added Resellers (VARs)

Recent Developments

- In October 2022, Vitronic (Germany) has recently expanded its facilities in Louisville, Kentucky (US). This expansion aims to provide additional capacity for regional engineering and customer collaboration centers that are dedicated to innovation.

Market Segment

This study forecasts revenue at global, regional, and country levels from 2019 to 2032. Spherical Insights has segmented the global surface inspection market based on the below-mentioned segments:

Surface Inspection Market, By Component

- Cameras

- Frame Grabbers

- Optics

- Lighting Equipment

- Processors

- Software

- Others

Surface Inspection Market, By Surface Type

- 2D

- 3D

Surface Inspection Market, By System

- Computer-based Systems

- Camera-based Systems

Surface Inspection Market, By Deployment

- Traditional

- Robotic Cell

Surface Inspection Market, By Industry Vertical

- Semiconductors

- Automotive

- Electrical & Electronics

- Food & Packaging

- Pharmaceutical

- Others

Surface Inspection Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of Middle East & Africa

Need help to buy this report?