Global Wedge Wire Screen Market Size, Share, Growth, and Industry Analysis, By Type (Flat Type, Cylinder Type, Basket Type, Sieve Bend Type), By Application (Water Treatment, Food and Beverage, Pulp and Paper, Mining and Mineral, Chemical and Petrochemical), and Regional Wedge Wire Screen and Forecast to 2033

Industry: Chemicals & MaterialsGlobal Wedge Wire Screen Market Insights Forecasts to 2033

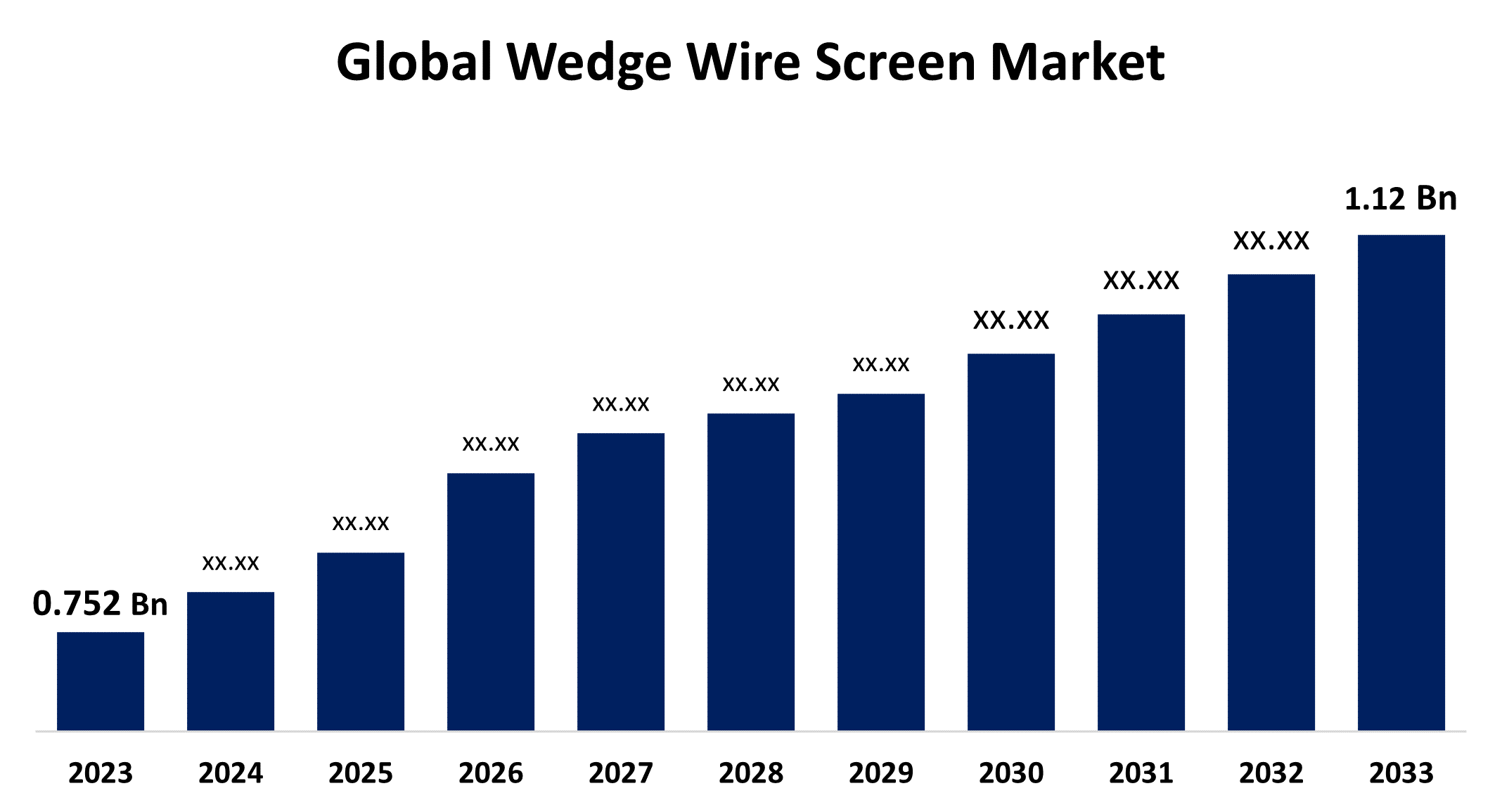

- The Global Wedge Wire Screen Market Size was Valued at USD 0.752 Billion in 2023

- The Market Size is Growing at a CAGR of 4.06 % from 2023 to 2033

- The Worldwide Wedge Wire Screen Market Size is Expected to Reach USD 1.12 Billion by 2033

- Asia-Pacific is Expected to Grow the fastest during the forecast period.

Get more details on this report -

The Wedge Wire Screen Market Size is Anticipated to Exceed USD 1.12 Billion by 2033, Growing at a CAGR of 4.06 % from 2023 to 2033.

WEDGE WIRE SCREEN MARKET REPORT OVERVIEW

The wedge wire screen is a popular metal mesh element used for desliming and dehydration in sieving and filtering applications. The components of a wedge wire screen are stainless steel support rods (also known as triangle wire, round bar, flat bar, or wedge wire) and surface profiles made of triangle wire. It creates a variety of V-shaped slots with large bottom openings and narrow top openings, and it performs exceptionally well against corrosion while offering high flow rates and outstanding chemical stability. The perfect gap size of wedge wire screens provides effective separation of particles and liquids, resulting in great filtration efficiency. Wedge wire screens can be adjusted to obtain precise particle sizing, making them perfect for applications that require a certain particle size distribution. The sturdy structure of wedge wire screens enables high flow rates while reducing pressure drop and assuring continuous operation. The V-shaped wires of wedge wire screens enhance self-cleaning, which reduces the need for manual maintenance while enhancing operational efficiency. Wedge wire screens are manufactured from high-quality materials that are resistant to corrosion and wear, ensuring a long lifespan and low downtime. Wedge wire screen demand shall be driven throughout the projected period by an increase in demand from end-user sectors such as water treatment, petrochemicals, and the food industry. Additionally, wedge wire screens are an ideal tool for boring holes. These screens enable simple liquid flow and can withstand a wide range of pressures.

Report Coverage

This research report categorizes the market for the global wedge wire screen market based on various segments and regions forecasts revenue growth and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the global wedge wire screen market. Recent market developments and competitive strategies such as expansion, product launch, and development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the global wedge wire screen market.

Global Wedge Wire Screen Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2023 |

| Market Size in 2023: | 0.752 Billion |

| Forecast Period: | 2023-2033 |

| Forecast Period CAGR 2023-2033 : | 4.06 % |

| 2033 Value Projection: | USD 1.12 Billion |

| No. of Pages: | 189 |

| Tables, Charts & Figures: | 110 |

| Segments covered: | By Type, By Application |

| Companies covered:: | CP Screens, Gap Technology, HEIN, LEHMANN, Hendrick Screen Company, International Screen Supplies, Jagtap Engineering, Multotec, Optima International, Progress Eco, Steinhaus GmbH, TOYO SCREEN KOGYO CO, Trislot NV and Wedge Tech., Carbis Filtration, Concord Screen, and Others Key Vendors. |

| Pitfalls & Challenges: | COVID-19 Empact, Challenges, Future, Growth, & Analysis |

Get more details on this report -

DRIVING FACTORS:

The product demand rises as a result of growing interest from end-user sectors can boost the market growth.

The industries that use wedge wire screens the most include the chemical, mining, gas oil, and paper sectors. It is reasonably sturdy and long-lasting, and its bigger drainage surface improves water flow. They are mostly utilized in end-use sectors for media retention, filtration, and separation. They are usually constructed of stainless steel. Furthermore, less power is needed at the pump load to pump the same volume of water due to decreased frictional head losses and greater discharge. Consequently, every one of these industries is greatly impacted by the expansion of the wedge wire screen market. The growing need for wastewater treatment solutions, strict environmental laws pertaining to water quality, and improvements in industrial processes necessitating effective solids-liquid separation are all contributing factors to the wedge wire screen market's growth.

RESTRAINING FACTORS

The small configuration of conventional wedges impedes market growth.

The narrow designs of traditional wedges cause a pressure drop across the screen basket to grow quickly, which in turn increases the amount of pumping energy needed to make up for the screening capacity restriction. These issues are anticipated to hinder sales in the global market during the forecast market.

Market Segmentation

The wedge wire screen market share is classified into type and application.

The flat type segment has the highest share of the market over the forecast period.

Based on type, the wedge wire screen is classified into flat type, cylinder type, basket type, and sieve bend type. Flat wedge wire screening provides a flawlessly smooth and level surface. In contrast to sieve bend screens and cylinder wedge screens, flat wedge wire screens can be made with strength and open area to meet the needs of any application in mind. Support rods and V-shaped profile wire are used to create flat wedge screen panels. In a variety of architectural contexts, flat wedge wire screens are utilized as floor grates to conceal water runoff drains in locations including driveways, parking lots, retail malls, and car parks. Additionally, it can resolve issues with liquid cooling, food products, paints, oils, greases, water, fuels, and solid/liquid and solid/gas separation.

The water treatment segment owing to the largest share of the market during the forecast period.

Based on application, the wedge wire screen is classified into water treatment, food and beverage, pulp and paper, mining and mineral, and chemical and petrochemical. In several aspects of water treatment, including sludge treatment, solid-liquid separation, flow management, and filtering wedge wire screens are essential. These products effectively aid in the filtration, separation, and flow regulation of water, and they are vital to the preservation of the environment and the sustainable use of water resources. To stop groundwater pollution, wedge wire can filter out sand, gravel, and other particles. To enhance the quality of municipal water, wedge wire is used to remove solid contaminants from water. Fish and other aquatic life are kept safe from the water intake system by the presence of wedge wire.

Regional Segment Analysis of the Global Wedge Wire Screen Market

- North America (U.S., Canada, Mexico)

- Europe (Germany, France, U.K., Italy, Spain, Rest of Europe)

- Asia-Pacific (China, Japan, India, Rest of APAC)

- South America (Brazil and the Rest of South America)

- The Middle East and Africa (UAE, South Africa, Rest of MEA)

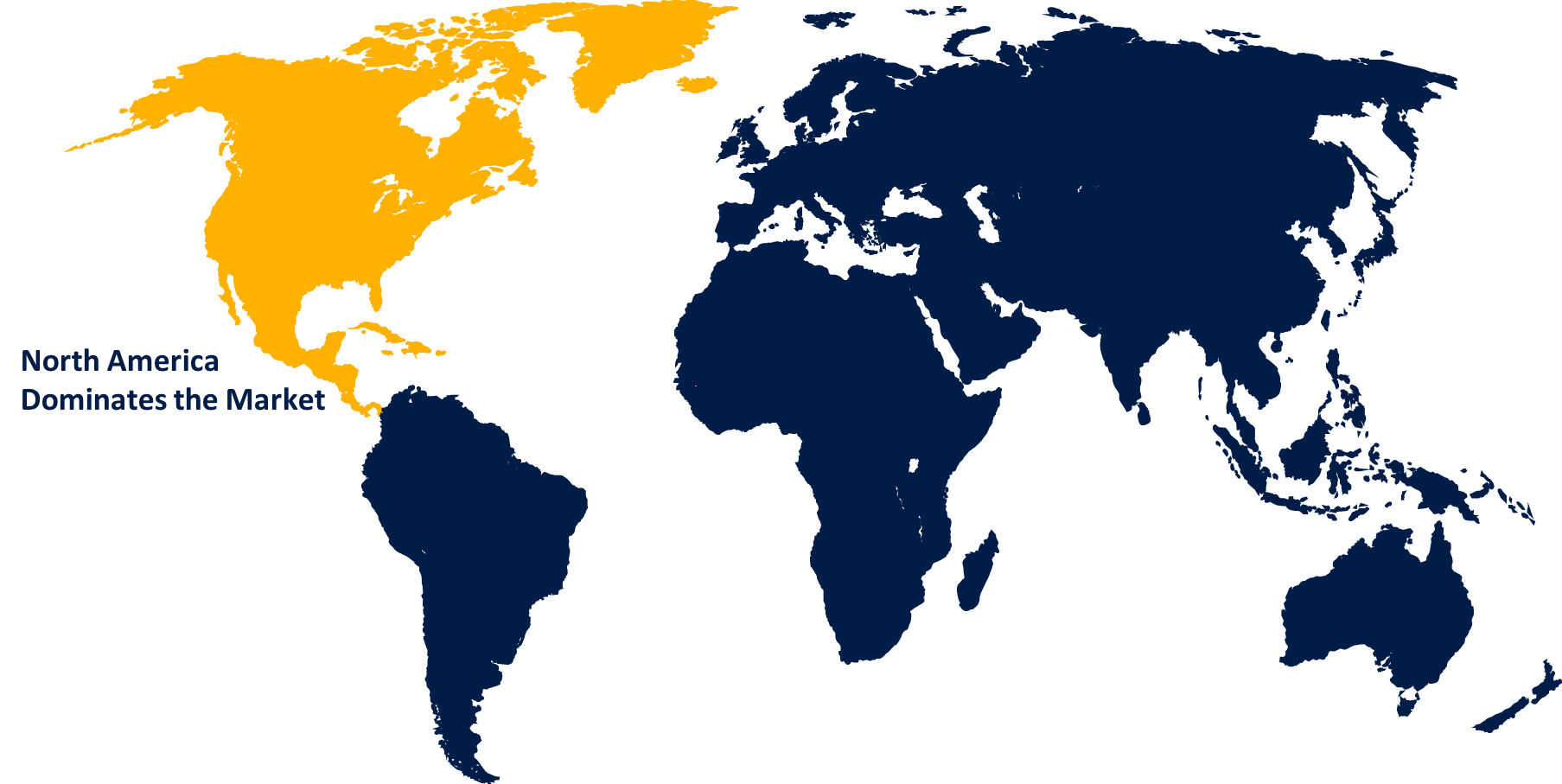

North America is having the biggest share of the wedge wire screen market throughout the forecast period.

Get more details on this report -

North America is most likely to hold a dominant market share in the wedge wire screen industry. The growing applications in fruit processing and wastewater treatment, which are anticipated to propel the market in the upcoming years, are responsible for this market expansion. Additionally, the highly developed agricultural sector in North America offers an infinite supply of premium organic raw materials for the production of organic fertilizers, which spurs further expansion in the fertilizer sector. The market is anticipated to expand further as a result of its increasing use in fertilizer manufacturing. The demand for wedge wire screens is expected to rise throughout the forecast period due to their widespread use in the manufacturing of fertilizer.

The Asia-Pacific is the fastest-growing region over the projected timeframe.

The demand for wedge wire screens is anticipated to increase in the Asia-Pacific area due to their growing use in the photochemical and mining industries. Because of its consistent filtration precision and ability to be frequently used and function dependably in end-use sectors, the region is anticipated to increase at the fastest rate. In this market, wedge wires offer a significant advantage due to their vast range of filtering choices.

Competitive Analysis:

The report offers the appropriate analysis of the key organizations/companies involved within the global wedge wire screen market along with a comparative evaluation primarily based on their product offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborative analysis focusing on the current news and developments of the companies, which includes product development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

List of Key Companies

- CP Screens

- Gap Technology

- HEIN

- LEHMANN

- Hendrick Screen Company

- International Screen Supplies

- Jagtap Engineering

- Multotec

- Optima International

- Progress Eco

- Steinhaus GmbH

- TOYO SCREEN KOGYO CO

- Trislot NV and Wedge Tech.

- Carbis Filtration

- Concord Screen

- Others

Key Target Audience

- Market Players

- Investors

- End-users

- Government Authorities

- Consulting And Research Firm

- Venture capitalists

- Value-Added Resellers (VARs)

Market Segment

This study forecasts revenue at global, regional, and country levels from 2020 to 2033. Spherical Insights has segmented the global wedge wire screen market based on the below-mentioned segments:

Global Wedge Wire Screen Market, By Type

- Flat Type

- Cylinder Type

- Basket Type

- Sieve Bend Type

Global Wedge Wire Screen Market, By Application

- Water Treatment

- Food and Beverage

- Pulp and Paper

- Mining and Mineral

- Chemical and Petrochemical

Global Wedge Wire Screen Market, By Regional

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

Frequently Asked Questions (FAQ)

-

1. What is the CAGR of the global wedge wire screen market over the forecast period?The global wedge wire screen market size is expected to grow from USD 0.752 Billion in 2023 to USD 1.12 Billion by 2033, at a CAGR of 4.06 % during the forecast period 2023-2033.

-

2. Which region is expected to hold the highest share in the global wedge wire screen market?North America is projected to hold the largest share of the global wedge wire screen market over the forecast period.

-

3. Who are the top key players in the wedge wire screen market?CP Screens, Gap Technology, HEIN, LEHMANN, Hendrick Screen Company, International Screen Supplies, Jagtap Engineering, Multotec, Optima International, Progress Eco, Steinhaus GmbH, TOYO SCREEN KOGYO CO, Trislot NV and Wedge Tech, Carbis Filtration, Concord Screen, and Others.

Need help to buy this report?